MPI, based in southeastern Michigan, is a worldwide provider of both magnetic and non-magnetic material handling solutions. MPI leads the industry by continuously engineering inventive magnetic equipment and advancing customer education, though significant investments in research and development and proactive product training.

Founded in 1981, MPI was formed to advance development of permanent magnet technology used in industry. Along with the company’s initial mission to engender research and development, the founders also focused on customer education, which would allow users to better select and maintain purchased equipment. These cornerstone principles still guide the company and its management team.

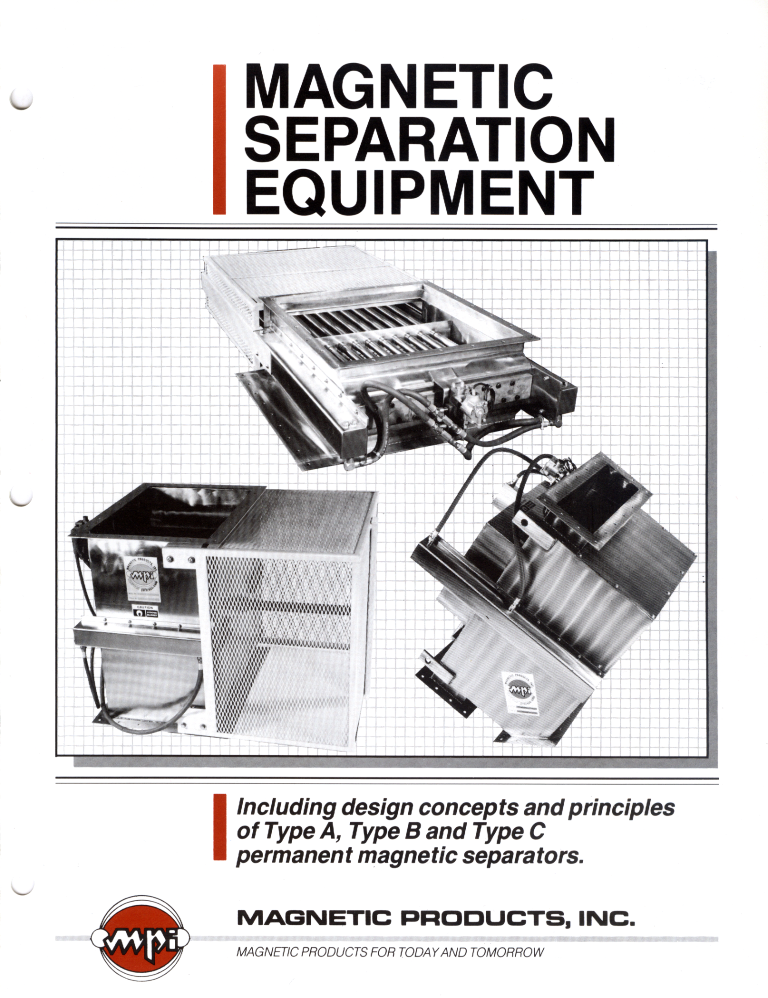

MPI’s first goal was to improve the performance of permanent magnetic separators. Within five years, MPI was to implement dramatic changes in equipment design that remain in place today. As a result of MPI’s engineering and development, easy-to-clean manually operated permanent magnets and self-cleaning automatic permanent magnetic separators are common worldwide. MPI is proud to have set the industry standard for permanent magnet separator equipment design and performance.

As MPI has grown over three decades, the same focus on product development and improvement has remained, and has been expanded to include magnetic conveying, automation and material handling equipment systems as well as metal detection.

From its beginnings, MPI recognized the need to educate customers to understand, evaluate and specify their applications, as well as to select and maintain magnetic equipment. Promoting and sponsoring industry education ensures that users are able to determine and understand both the expectations and limitations of equipment before investments are made. A basic understanding of the workings of magnetic equipment allows users to determine whether existing equipment can meet process expectations or whether new equipment should be considered. MPI staff is frequently invited to speak at multinational corporations, engineering firms, industry associations and educational institutions on topics related to magnets and their application in industry.

Going forward, MPI will continue its tradition of advancing product performance and expanding its line of metal control systems and material handling equipment solutions. By interacting closely with its customers and focusing on a market-driven product line, MPI has positioned itself to readily meet the challenges of today’s dynamic global economy.

Timeline of Achievements

2025

Kyle Rhodes takes over at MPI President.

MPI applies for Hazardous Location certification for suite of Intell-I-Mag® magnetic separators.

2024

MPI patents Intell-I-Mag® Liquid Magnet - the Blade Magnet.

MPI patents Intell-I-Mag® Pneumatic Line Magnetic - the Wave Magnet.

MPI launches Intell-I-Mag® mobile app in Apple and Google Play stores.

MPI refreshes brand and promises "Practical Guidance. Uncompromising Service."

MPI celebrates 10 years without a lost time accident.

2021

MPI patents Intell-I-Mag® the revolutionary next step in magnetic separation.

Releases Magnet Audit 2.0 program.

MPI celebrates 40 years of business operations.

2020

MPI expands Automation and Workholding products.

2019

MPI builds a 224′ Beltless Magnetic Conveyor Central Scrap System.

MPI patents the Sanitary Toolless Drawer Magnet.

2017

All MPI Regional Sales Managers become Certified Food Safety HACCP (Hazard Analysis Critical Control Point) managers.

2015

MPI begins offering subscribed service plans for continued product validation.

MPI receives USDA certification in the dairy category and meat and poultry category for its plates, grates, drawers, and liquid trap magnets.

MPI patents a magnetic separator system for the recycling industry.

2014

MPI patents its electric shakers.

MPI adds checkweigh and X-Ray inspection to its electronic inspection product line.

2013

MPI becomes a certified UL/ETL 61010-1 USA & CSA/Canada and 508A electrical panel shop.

2012

MPI launches its new noble purpose statement: Protecting and Moving the World through Innovation.

2010

MPI becomes the distributor for Cassel metal detection and checkweighing equipment.

MPI patents its first-generation electric shaker conveyors.

2007

MPI becomes the distributor for Eclipse Magnetics products in North America.

2006

MPI patents the seal-less pneumatic shaker conveyor and introduces the next generation electric shaker.

2001

MPI patents the seal-less pneumatic beltless magnetic conveyor.

MPI patents its automatic Self-Cleaning Drawer Magnet.

2000

MPI’s founder is profiled for his business success and continued growth.

1995

MPI introduces its pneumatic shaker

MPI is featured in the Detroit Free Press for its growth into Europe and Mexico.

MPI expands its manufacturing facility, doubling capacity

1994

MPI’s building wins an award and is featured in Metal Construction News Magazine.

1993

July 1, 1993 – MPI relocates to Highland, Michigan, into its newly constructed state-of-the-art R&D and manufacturing facility, more than doubling its current operations

January 21, 1993 – Groundbreaking of the future site of MPI’s current manufacturing facility.

1991

MPI patents the reciprocating Drawer Magnet.

1990

MPI begins its metal fabrication services business unit.

1989

MPI patents the magnetic can-laner conveyor

1985

MPI relocates and doubles its manufacturing operations.

1984

MPI introduces Magnet Audit Services

1983

MPI introduces its first version of the educational training presentation “A Magnet is Not Just A Magnet”

MPI introduces the first generation family of self-cleaning permanent magnetic separators with its Self-Cleaning Chute Magnets

1981

MPI begins operations in Walled Lake, Michigan.