MPI's Magnetic Beltless and Belted Conveyors are designed for efficient movement and control of ferrous materials, including parts, scrap, and finished components. The beltless models utilize internal magnetic systems for transportation across stainless steel surfaces, reducing maintenance needs by eliminating external moving parts. In contrast, belted magnetic conveyors blend traditional belt functionality with magnetic force for secure handling of challenging materials like sharp, oily, or hot items in various industrial applications. These conveyors enhance equipment protection, minimize downtime, and prolong operational lifespan by ensuring smooth, jam-free material flow. Suitable for both simple and flexible automation needs, MPI's magnetic conveyors deliver robust performance and seamless integration into production lines.

MPI’s Shaker and Vibratory Conveyors provide dependable, low-maintenance solutions for moving scrap, parts, or bulk materials through manufacturing processes. Ideal for metal stamping, machining, and foundry applications, these conveyors use controlled linear motion to transport materials quietly and cleanly, with fewer jams and lower energy than traditional belt systems. MPI’s shaker and vibratory systems offer robust performance with minimal moving parts for high-reliability scrap and part handling. Their energy-efficient, jam-resistant operation increases uptime and reduces floor maintenance, making them ideal for harsh, high-volume environments that demand simplicity and durability.

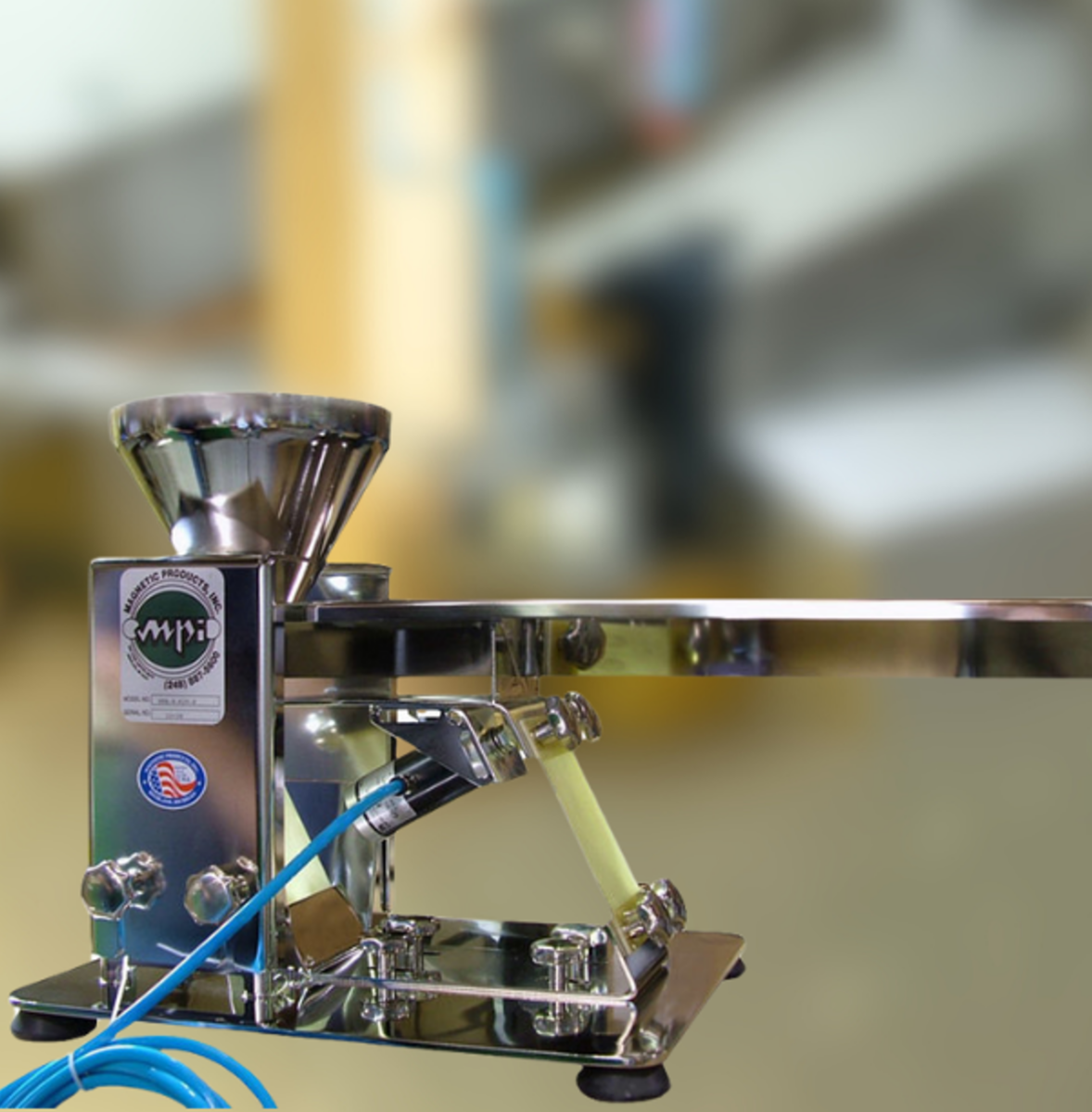

Compatibility Check - What Type of Magnetic Separation Fits Your Application

MPI provides Magnetic Beltless and Belted Conveyors for effective handling of ferrous materials, such as parts, scrap, and finished products. Beltless models utilize internal magnetic systems to move items over stainless steel surfaces, minimizing maintenance by removing external moving parts. Belted conveyors incorporate magnetic forces with traditional belts to tackle tough materials, including sharp or hot items, suitable for diverse industrial applications. Both systems enhance equipment protection, reduce downtime, and extend operational lifespan by ensuring smooth, jam-free operation. MPI’s magnetic conveyors accommodate varying automation needs, while their Shaker and Vibratory Conveyors offer reliable, low-maintenance solutions for transporting materials in manufacturing, particularly in metal stamping, machining, and foundry settings. These conveyors employ controlled linear motion for quiet, efficient material transport, decreasing jams and energy consumption compared to standard belt systems. With few moving parts, MPI's shaker and vibratory systems provide strong performance and enhanced reliability for high-volume scrap and part handling, improving uptime and minimizing floor maintenance in demanding environments.