Magnetic Chute Separators are designed to effectively capture ferrous tramp metal from heavy product flows, preventing clogs that can occur with traditional magnetic tubes, especially in abrasive materials. They come in various designs, including manual, quick-clean, and automated options, and utilize advanced magnetic technologies for optimal separation performance. Features like the proprietary Sani-TIGHT Seal Gasket minimize leaks and replacement needs, while flexible cleaning configurations cater to different operational demands. MPI offers chute magnets for diverse industries, including food and beverage, pharmaceuticals, plastics, mining, and agriculture, ensuring product purity and compliance with FDA, USDA, and other regulations. These separators operate by generating a strong magnetic field to attract and capture ferrous contaminants as bulk material flows through sloped or vertical chutes, facilitating efficient and cost-effective metal removal. Their robust construction allows for durability in harsh environments, making them vital for maintaining safety and efficiency in various applications while protecting equipment from damage caused by metal contaminants.

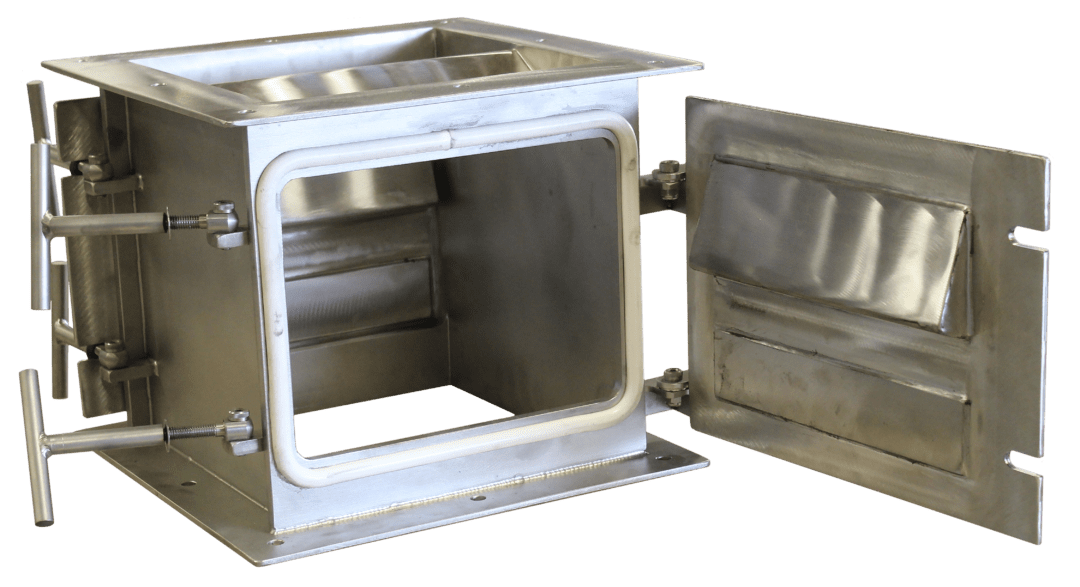

MPI Manual Clean Chute Magnets effectively capture and remove tramp metal contaminants from free-flowing materials in vertical or near-vertical chute applications. They are ideal for industries such as food processing, plastics, pharmaceuticals, and mining. Operators manually remove collected contaminants to maintain peak magnetic performance, ensuring reliable operation and ease of maintenance. Manual Clean Chute Magnets offer the highest magnetic strength of the fleet.

MPI Quick Clean Chute Magnets are designed for high-volume, gravity-fed product flows, effectively capturing medium to large ferrous contaminants without causing clogging or bridging, unlike magnetic grates. These magnets enhance product quality and protect downstream equipment in various industries, including food processing, pharmaceuticals, and chemical processing. They facilitate efficient tramp metal removal while minimizing maintenance downtime through a quick-clean mechanism that allows operators to easily dispose of collected contaminants.

MPI Self-Clean Chute Magnets offer fully automated tramp metal removal. Designed for continuous operation, these magnets feature a hands-free cleaning mechanism controlled by a timer or sensor, eliminating manual intervention. The powerful Ceramic 8 permanent magnet attracts and retains metal debris, which is then automatically removed, ensuring consistent performance and minimizing downtime. These self-cleaning magnets are ideal for industries where operational efficiency and contamination control are critical.

Compatibility Check - Magnetic Chute Comparison

Unique Benefits and Considerations

| Chute Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Manual-Clean Chute Magnet | Affordable and simple to maintain. Strongest magnetic force in the fleet due to no cleaning mechanism air gap in design. | Requires manual cleaning, which can increase downtime in high-volume applications. |

| Quick-Clean Chute Magnet | Faster cleaning process reduces downtime and labor. | Higher upfront cost compared to manual models. |

| Self-Clean Chute Magnets | Fully automated cleaning mechanism minimizes manual intervention and operational disruption. | Requires more complex installation and higher initial investment. |

Industries, Applications and Regulations

For assistance in selecting the most suitable chute magnet for your application or for additional customization options, contact Magnetic Products Inc. at info@mpimagnet.com today to speak with our team of experts!