Maximum Magnetic Filtration

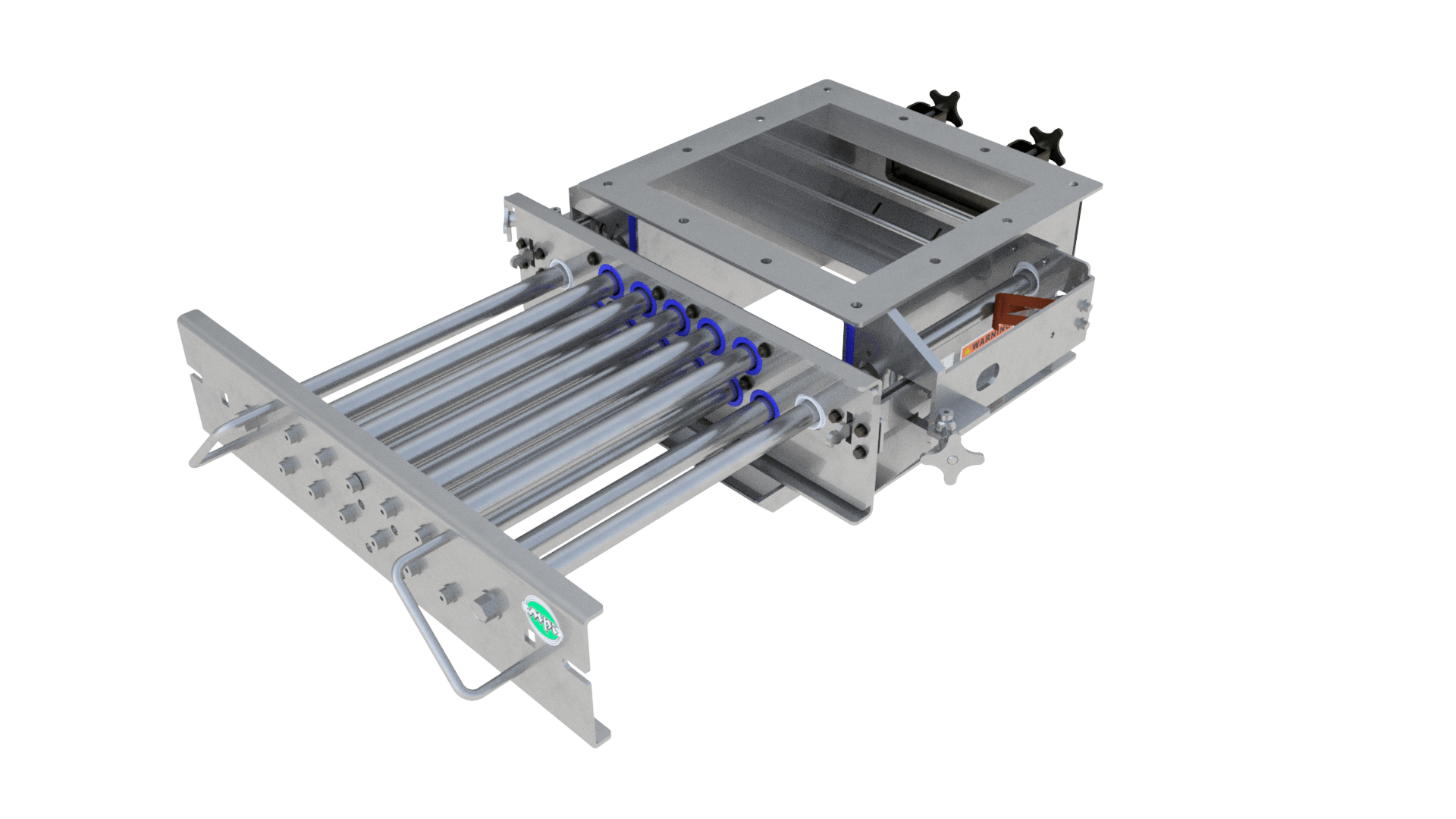

Magnetic Products Inc. (MPI) Quick Clean Drawer Magnets are expertly engineered to effectively extract ferrous metal contaminants from dry, free-flowing materials in gravity-fed systems, all while significantly reducing downtime. Ideal for sectors such as food processing, plastics, chemicals, and pharmaceuticals, these drawer magnets ensure dependable contamination control, boost operational efficiency, and lower maintenance labor. The innovative quick-clean mechanism simplifies the process of removing captured metal debris, greatly decreasing the time and effort involved in maintenance compared to traditional manual models. This system is equipped with high-intensity rare earth magnetic tubes arranged in a staggered pattern to optimize product contact and enhance filtration effectiveness. During the cleaning process, operators can effortlessly slide out the magnetic assembly, which automatically clears collected ferrous materials from the tubes using a mechanical stripper assembly. The contaminants are then directed into a designated discharge chute or collection tray, facilitating a smooth and hygienic removal process. This design reduces direct handling of captured metals, improves worker safety, and minimizes production downtime, making it a superior choice for challenging industrial environments.

Benefits of the Manual Quick-Clean Drawer Magnet From Magnetic Products, Inc

-

Quick-Clean Mechanism

Reduces downtime and simplifies the cleaning process with a pull-and-wipe design.

-

High-Intensity Magnetic Tubes

Rare-earth or ceramic magnets capture even the smallest ferrous particles to ensure product purity.

-

Durable Construction

Stainless-steel housing for superior strength and corrosion resistance.

-

Easy Manual Cleaning

Simple and quick cleaning process reduces downtime and ensures operational efficiency.

-

Compact and Modular Design

Fits easily into existing systems with minimal modifications. Multiple sizes and layouts to accommodate specific processing needs.

-

FDA-Compliant Models

Options available for food-grade applications.

Manual Quick-Clean Drawer Magnet Product Details

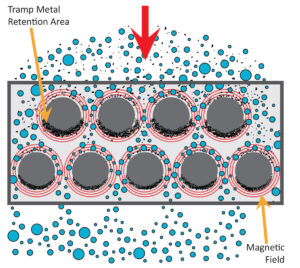

MPI Quick Clean Drawer Magnets efficiently remove ferrous contaminants from gravity-fed dry materials using high-intensity magnetic tubes. As material flows through the housing, two staggered rows of 1” diameter magnetic tubes create an optimized magnetic circuit, capturing tramp metal and preventing wash-off.

MPI Quick Clean Drawer Magnets efficiently remove ferrous contaminants from gravity-fed dry materials using high-intensity magnetic tubes. As material flows through the housing, two staggered rows of 1” diameter magnetic tubes create an optimized magnetic circuit, capturing tramp metal and preventing wash-off.

When cleaning is required, the operator activates the quick-clean mechanism, pulling the magnetic tubes through non-metallic UHMW stripper assemblies. This process safely removes contaminants from the tubes and deposits them into a collection tray, ensuring fast, easy maintenance with minimal operational disruption.

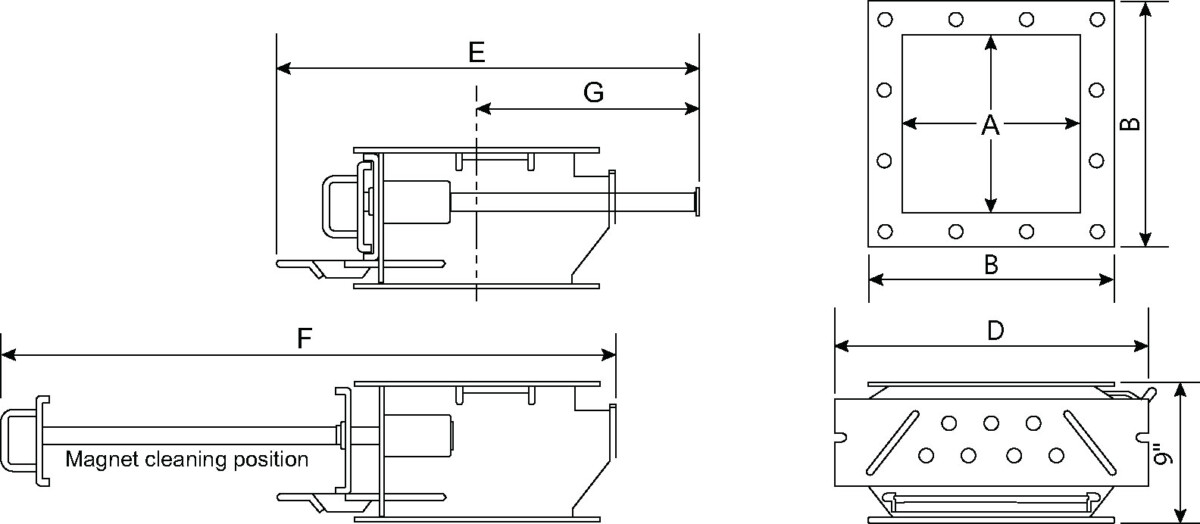

Manual Quick-Clean Drawer Magnet Specification Table

US Customary Units

| QUICK-CLEAN DRAWER MAGNET MODEL # | (A) FLOW OPENING (IN.) | (B) FLANGE WIDTH (IN.) | (D) OVERALL WIDTH (IN.) | (E) OVERALL LENGTH - DRAWER CLOSED (IN.) | (F) OVERALL LENGTH - DRAWER OPEN (IN.) | (G) REAR EDGE TO CENTER (IN.) | # MAGENT TUBES (2 ROWS) | APROX. WEIGHT (LBS.) | FLOW RATE (FT/HR) |

|---|---|---|---|---|---|---|---|---|---|

| DMU-206-QC | 6 | 10.25 | 18.25 | 23.71 | 27 | 14.8 | 5 | 66 | 260 |

| DMU-208-QC | 8 | 12.25 | 20.25 | 25.71 | 31 | 15.8 | 7 | 77 | 600 |

| DMU-210-QC | 10 | 14.25 | 22.25 | 29.71 | 35 | 18.8 | 9 | 106 | 1,350 |

| DMU-212-QC | 12 | 16.25 | 24.25 | 33.71 | 39 | 21.8 | 11 | 120 | 2,400 |

| DMU-214-QC | 14 | 18.25 | 26.25 | 37.71 | 43 | 24.8 | 13 | 135 | 3,037 |

Manual Quick-Clean Drawer Magnet Installations and Variations

Manual Quick-Clean Drawer Magnet in Flour Mill

Manual Quick-Clean Drawer Magnet for Recycling Application

Manual Quick-Clean Drawer Magnet Installed in Sugar Refinery