Ideal for Heavy Product Flows

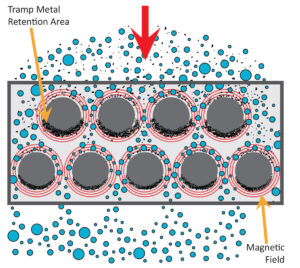

The MPI 1" Tube Self-Clean Drawer Magnets feature a specialized magnetic circuit for effectively capturing small metal contaminants from dry powders or granular products in gravity-fed chutes. The Automated Self-Clean Drawer Magnet series enhances equipment protection during processing operations like milling and mixing while maintaining high product quality through its automatic cleaning system. Equipped with two tiers of 1-inch, high-intensity rare earth magnetic tubes, the magnets maximize contact with the product stream, effectively removing ferrous tramp metal. Their staggered arrangement prevents product bridging and optimizes filtration efficiency. As the product flows, tramp metal is attracted to the tubes, and a pneumatically operated system cleans the contaminants to a designated area, ensuring a clean product stream. The self-clean drawer magnets utilize two tiers of magnetic tubes for superior filtration, with a design allowing one drawer to clean while the other filters the product, thereby maintaining uninterrupted flow. The cleaning cycle is robust, featuring a solenoid-actuated mechanism that safely extracts tramp metal outside the product flow area, allowing the system to resume operations seamlessly.

Benefits of the One Inch Tube Self-Clean Drawer Magnet From Magnetic Products, Inc

-

High-Strength Magnetic Circuit

- Four-tier high-intensity rare earth magnets maximize metal separation through direct product contact.

- Dual-tier magnetic tubes (1” diameter) ensure optimal filtration by capturing tramp metal.

- Staggered tube layout prevents bridging and choking while enhancing contamination removal.

-

Continuous Product Flow

- No need to stop product flow during the cleaning cycle, ensuring uninterrupted processing.

- Two magnet rows remain active during cleaning, always maintaining product protection.

-

Automated Cleaning Cycle

-

- Solenoid-actuated cleaning system reduces manual labor and downtime.

- Start: Magnetic tubes retract through the stripper assembly, depositing tramp metal outside the product flow.

- Finish: Tubes return to the run position for continued operation.

-

Enhanced Sealing & Durability

- Floating Stripper Seal adjusts to tube wear, extending replacement intervals.

- Stripper Latch prevents accidental cleaning within the product flow area.

-

Sani-TIGHT Seal™ Gasket

-

- Compression-style O-ring for a 100% positive seal that cannot be over-compressed.

- ½” thick machined stainless sealing plate for durability.

- Sanitary, adhesive-free design allows easy removal and replacement during wash-downs.

-

Leak & Misalignment Prevention

-

- Extended drawer front minimizes product leakage for cleaner operation.

- Internal supports prevent tube misalignment, maintaining optimal magnet positioning.

-

Easy Maintenance & Access

-

- Rear access panel simplifies inspection and maintenance.

- Bolt-on stainless steel safety cage:

- Removable cover for magnet maintenance and testing.

- Multiple options for tramp metal recovery.

-

Static Discharge Protection

-

- Integrated grounding strap prevents static buildup, ensuring safe operation.

-

Hygienic & Durable Design

-

- Stainless steel construction ensures long-lasting, sanitary operation.

- High-temperature and wash-down-compatible components for food-grade and pharmaceutical applications.

One Inch Tube Self-Clean Drawer Magnet Product Details

MPI’s 1-inch Tube Self-Clean Drawer Magnets utilize a Type A magnetic circuit designed to efficiently capture small ferrous contaminants—such as metal shavings and wear particles—from dry powder or granular products in gravity-fed vertical chutes. This system enhances equipment protection during processing operations like milling, mixing, and extrusion while upholding high product quality through automatic, uninterrupted magnetic filtration.

Magnetic Filtration and Contaminant Capture

The drawer assembly contains multiple tiers of 1” diameter high-intensity rare earth magnetic tubes, ensuring maximum product contact for superior filtration. These tubes are strategically staggered to:

- Prevent bridging and choking in the product stream.

- Maximize ferrous tramp metal capture efficiency.

As materials flow through the housing, ferrous contaminants are drawn to the magnetic tubes, effectively removing metal impurities from the product stream.

Automated Cleaning Cycle

The pneumatically operated cleaning system removes contaminants without halting product flow, ensuring continuous operation. The system follows a precise cleaning cycle:

- Activation: A solenoid valve is manually or electrically triggered, initiating the cleaning process.

- Retraction: Pneumatic cylinders retract, pulling the magnetic tubes through a stripper assembly, which automatically removes and directs collected tramp metal to a designated disposal bin.

- Return to Operation: The cylinders extend back into position, pushing the magnetic tubes through the stripper assembly into the housing, resuming full filtration.

This dual-drawer design allows one drawer to clean while the other remains active, ensuring an uninterrupted product stream.

Contaminant Removal and Collection

Captured ferrous contaminants are directed into a separate collection bin outside the product stream, preventing metal reintroduction and maintaining a sanitary production environment. Cleaning cycles can be triggered via:

- Preset Timer (scheduled cleaning cycles)

- Sensor Activation (detects metal buildup and triggers cleaning as needed)

Durable, Hygienic Construction

- All-stainless steel housing ensures durability, corrosion resistance, and compliance with food and pharmaceutical safety standards.

- Sani-TIGHT Seal™ gasket provides a 100% leak-proof, sanitary seal, preventing contamination and ensuring wash-down compatibility.

By automating the removal of ferrous contaminants, MPI’s Self-Clean Drawer Magnets provide a low-maintenance, high-efficiency solution for metal separation, delivering unmatched reliability in demanding processing environments.

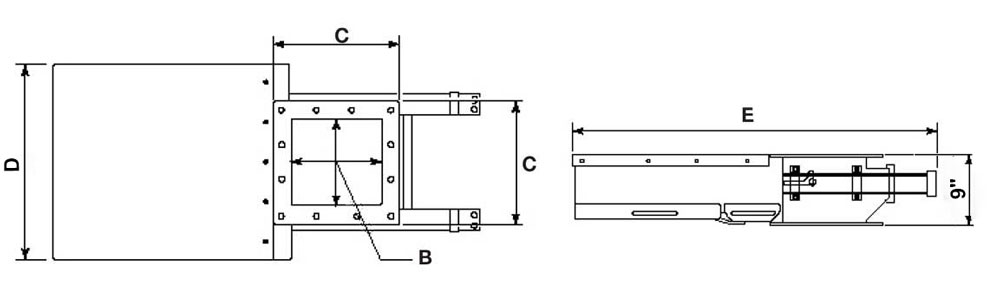

One Inch Tube Self-Clean Drawer Magnet Specification Table

US Customary Units

| SELF-CLEAN DMU MODEL # | (B) FLOW OPENING (IN.) | (C) FLANGE WIDTH (IN.) | (D) OVERALL WIDTH (IN.) | (E) OVERALL LENGTH (IN.) | # OF MAGNETIC TUBES (2 ROWS) | APPROX. WEIGHT (LBS.) | FLOW RATE (FT³/HOUR) |

|---|---|---|---|---|---|---|---|

| DMU-208-SC | 8² | 12.25 | 22.75 | 43 | 7 | 170 | 600 |

| DMU-210-SC | 10² | 14.25 | 24.75 | 45 | 9 | 180 | 1,350 |

| DMU-212-SC | 12² | 16.25 | 26.75 | 47 | 11 | 190 | 2,400 |

| DMU-214-SC | 14² | 18.25 | 28.75 | 49 | 13 | 200 | 3,750 |

| DMU-216-SC | 16² | 20.25 | 30.75 | 51 | 15 | 230 | 3,750 |

| DMU-218-SC | 18² | 22.25 | 32.75 | 53 | 17 | 270 | 5,400 |

| DMU-220-SC | 20² | 24.25 | 34.75 | 55 | 19 | 300 | 6,337 |

One Inch Tube Self-Clean Drawer Magnet Installations and Variations

1-Inch Tube Self-Clean Drawer Magnet Designed for Salt Refinery

Custom 1-Inch Tube Self-Clean Drawer Magnet Designed with Enclosed Cylinders for Bulk Powder Application

1-Inch Tube Self-Clean Drawer Magnet for Textile Application