Evenly Distribute Contaminant-Free Feed

Magnetic Products Inc. (MPI) Quick Clean Free Flow Magnets are expertly designed to eliminate ferrous contaminants from dry, granular, or powdered materials within free-flowing systems. Tailored for high-volume operations, these magnets feature a quick-clean mechanism that reduces maintenance downtime and optimizes contaminant extraction. They are particularly suited for industries such as food processing, pharmaceuticals, plastics, recycling, and chemicals, where product purity is paramount.

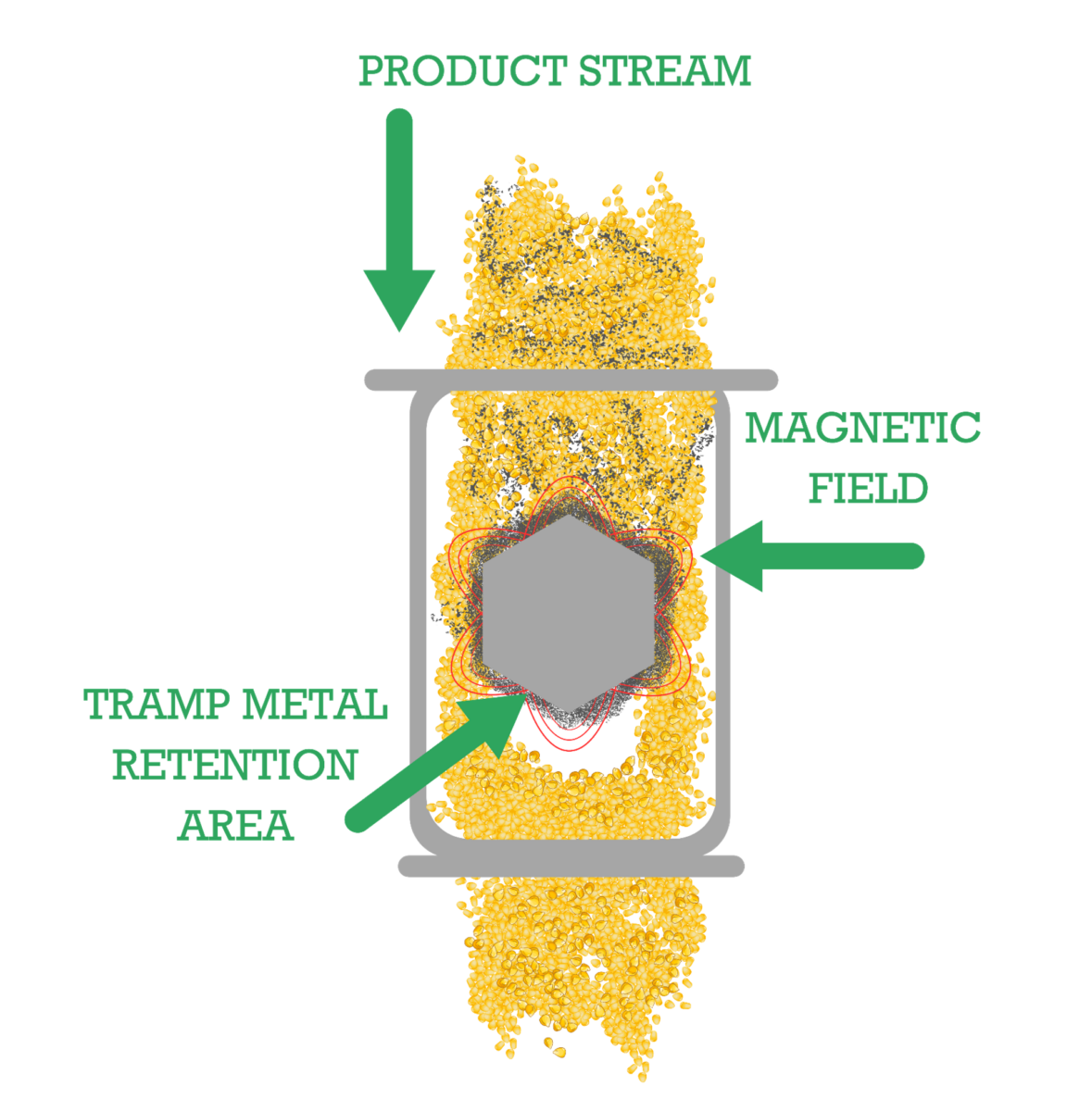

MPI’s unique Quick-Cleaning Free-Flow Cylinder Magnets are intended to capture both large and small tramp metal from high-volume, abrasive, vertical gravity-fed product streams, including grain and mining materials. The FFC-QC Series magnets ensure maximum retention of ferrous tramp metal in product streams where the risk of “wash-off” is a significant concern.

Benefits of the Quick-Clean Free Flow Magnet From Magnetic Products, Inc

-

Quick-Clean Mechanism

Simplifies the cleaning process with a pull-and-wipe design, reducing downtime and labor.

-

High-Intensity Magnetic Circuit

Rare-earth magnets effectively capture fine and coarse ferrous contaminants. Heavy-duty hexagon-shaped magnet.

-

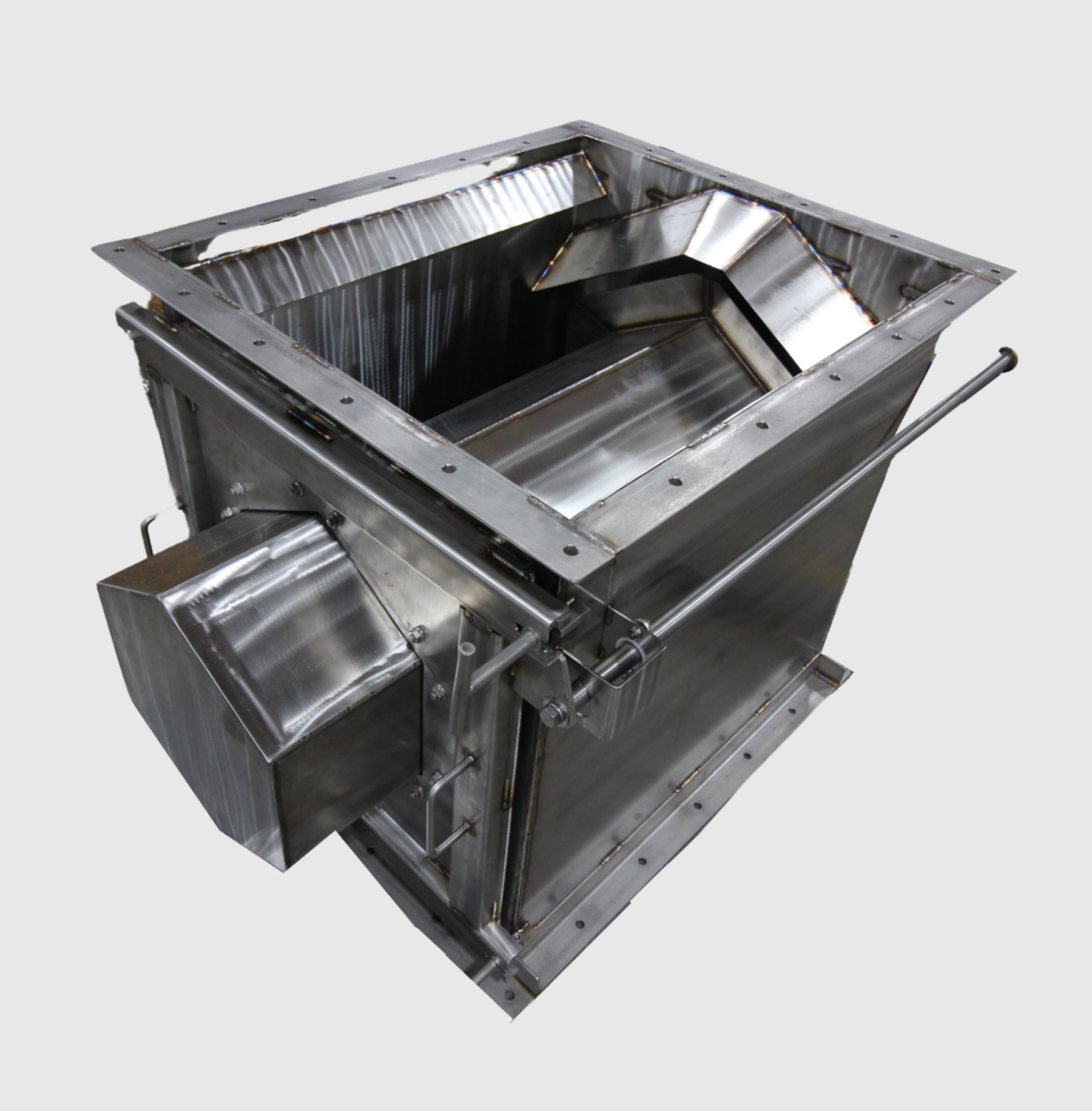

Durable Construction

100% stainless steel housing ensures long-lasting performance and resistance to corrosion. Removable stripper shell–provides three wear surfaces to handle abrasive products

-

Compact Design

Easily integrates into existing systems with minimal modifications.

-

Food-Grade Options

- FDA approved “O-Ring Cord” compression-style gasket which offers bullet-proof seal and virtually eliminates replacement. FDA-compliant materials and coatings available for hygienic applications in food and pharmaceutical environments.

-

Versatile Configurations

Customizable to suit various material flow rates and processing requirements.

Quick-Clean Free Flow Magnet Product Details

Magnetic Products Inc. (MPI) has created the Quick-Clean Free Flow Feeder Magnet to eliminate ferrous contaminants from bulk materials in gravity-fed systems effectively. These magnets are exceptionally proficient in abrasive industries such as grain processing and mining.

As bulk materials flow through the feeder, they interact with a powerful magnetic assembly to attract and capture ferrous impurities. This process ensures that only purified material continues downstream, preventing contamination.

At the heart of the system is a six-sided permanent magnet encased in stainless steel. As materials navigate around the magnet, ferrous metals accumulate on its surface. The six-sided configuration merges the benefits of both plate and grate magnets,

Like a grate magnet, it directs contaminants into direct contact with the magnet, thereby enhancing capture efficiency.

Like a plate magnet, each of its six surfaces produces a strong, extended magnetic field, attracting and retaining larger ferrous particles.

To avoid "wash-off," where the product flow could sweep away contaminants, the collected metals remain on the magnet's surface and rotate around it until they exit the flow area.

The system features a distinctive quick-clean stripper shell, enabling operators to eliminate captured contaminants swiftly. When cleaning is necessary, the operator extracts the magnetic assembly, wipes off the collected metal particles, and reinserts the unit to continue operations. This efficient cleaning process minimizes downtime and maintains smooth production.

The Quick-Clean Free Flow Feeder Magnet is engineered for use in gravity-fed and pneumatic conveying systems. It guarantees the effective removal of ferrous contaminants from free-flowing materials. Its high-intensity magnetic tubes deliver dependable performance in high-volume, abrasive material-handling environments.

By integrating efficient contamination capture with a user-friendly cleaning mechanism, MPI’s Quick-Clean Free Flow Feeder Magnet helps ensure optimal efficiency while reducing maintenance interruptions.

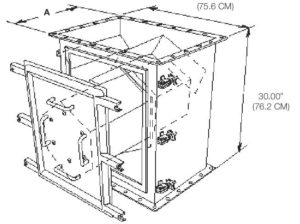

Quick-Clean Free Flow Magnet Specification Table

US Customary Units

| MODEL # | MAXIMUM INLET AREA OPENING (IN2) | (A) DEPTH (IN.) | APPROX. WEIGHT (LBS) |

|---|---|---|---|

| FFC-12-QC | 152 | 12 | 450 |

| FFC-18-QC | 216 | 18 | 632 |

| FFC-24-QC | 288 | 24 | 817 |

| FFC-30-QC | 360 | 30 | 1002 |

| FFC-36-QC | 432 | 36 | 1187 |

| FFC-42-QC | 504 | 42 | 1372 |

| FFC-48-QC | 576 | 48 | 1557 |

| MINI FREE FLOW QUICK-CLEAN SIZES | |||

| MFF-1408-QC | 36 | 8 | 85 |

| MFF-1410-QC | 48 | 10 | 100 |

| MFF-1412-QC | 60 | 12 | 115 |

| MFF-1414-QC | 72 | 14 | 130 |

| MFF-1416-QC | 84 | 16 | 145 |

| MFF-1418-QC | 96 | 18 | 160 |

| MFF-1420-QC | 108 | 20 | 175 |

Quick-Clean Free Flow Magnet Installations and Variations

Quick-Clean Free Flow Magnet for Grain Processing Application

Quick-Clean Free Flow Magnet Built for Abrasive Mining Application

Quick-Clean Free Flow Feeder Magnet with Intell-I-Mag to Reduce Downtime and Unnecessary Stoppages