Effective Removal of Unwanted Tramp Metal

For continuous, hands-free metal separation, MPI’s Self-Clean Suspended Receiving Belt Magnet / Cross Belt Separator is the ultimate solution. Designed to operate without manual intervention, this powerful cross-belt separator efficiently removes ferrous contaminants from conveyor-fed material streams, automatically discharging metal debris away from the product flow. This feature eliminates the need for regular cleaning stops, ensuring maximum uptime and reducing labor costs.

Constructed with heavy-duty stainless-steel housing and a high-intensity magnetic field, this unit is designed for harsh industrial environments, including mining, aggregates, recycling, and bulk material processing. The continuous self-cleaning system uses a motorized belt mechanism to remove metal contaminants, providing reliable and maintenance-free separation automatically. By preventing metal contamination and safeguarding downstream equipment, the Self-Clean RBM Plate Magnet enhances operational efficiency and ensures product integrity. All MPI Plate Magnets are Intell-I-Mag® Compatible.

Benefits of MPI's Self-Clean Suspended Receiving Belt Magnet/Cross Belt Separator

-

Extra-Wide Belt for Enhanced Protection

The self-cleaning cross-belt magnet features an extra-wide conveyor belt, ensuring complete coverage over the product flow. It also helps prevent tramp metal damage under the belt, extending the life of conveyor components and reducing maintenance costs.

-

Crowned Pulleys for Accurate Belt Tracking

Precision-engineered crowned pulleys maintain optimal belt alignment, preventing slippage and reducing wear. Ensures consistent metal removal performance, improving efficiency and minimizing operational disruptions.

-

Optional Bucking Magnet for Extended Magnetic Reach

An optional bucking magnet design increases the reach out of the magnetic field by 25%, enhancing separation efficiency. This separator is ideal for capturing deeper or more challenging ferrous contaminants in high-speed applications.

-

Powerful Drive System for Continuous Operation

It is equipped with a 1 HP or 2 HP drive motor, providing reliable and efficient belt movement. An integrated speed reducer optimizes performance, ensuring smooth and consistent operation in demanding environments.

-

High-Performance Permanent Ceramic 8 Magnet

It is constructed with Permanent Ceramic 8-magnet material, delivering strong, long-lasting magnetic separation. It is encased in stainless steel for enhanced durability and corrosion resistance, ensuring longevity in harsh industrial settings.

-

Adjustable Belt Take-Ups for Optimal Tension

Designed with adjustable belt take-ups, it allows operators to maintain proper belt tension and extend service life. It prevents unnecessary wear and slippage, reducing downtime and maintenance frequency.

-

Rugged, Welded Steel Framework for Heavy-Duty Applications

Even in the most demanding environments, the rugged steel frame construction provides unmatched durability and stability. It is engineered to withstand high impact loads and extended operational hours, ensuring reliable performance.

-

Integral Frame Suspension for Secure Installation

Features four integral frame suspension mounting eyelets, enabling quick and secure installation over conveyor systems. Ensures stable positioning, optimizing magnetic separation efficiency and maintaining long-term operational effectiveness.

Self-Clean Suspended Receiving Belt Magnet/Cross Belt Separator Product Details

MPI’s Self-Clean Suspended Receiving Belt Magnet (RBM) is an advanced tramp metal separation system designed to protect processing equipment and ensure product purity by continuously removing ferrous contaminants from material conveyed beneath it. The self-cleaning mechanism enhances efficiency by automatically discarding captured metal without interrupting production.

Step-by-Step Operation

Suspension & Positioning

- The RBM is suspended above a conveyor belt, positioned to intercept and extract ferrous contaminants from the material flow.

- Optimal suspension height is determined based on the application, ensuring maximum tramp metal capture while minimizing interference with the conveyed product.

- It is installed in a location where maintenance and cleaning can be easily performed without disrupting operations.

Magnetic Tramp Metal Capture

- As material moves beneath the suspended RBM, powerful permanent magnets generate a strong magnetic field that attracts and captures ferrous contaminants such as screws, nails, bolts, and metal shavings.

- The captured metal adheres to the magnetic plate surface, preventing it from continuing downstream and causing damage to processing equipment.

Continuous Self-Cleaning Mechanism

- The system features a motor-driven receiving belt that continuously moves across the face of the magnet.

- As the belt rotates, it pulls ferrous debris off the magnet’s surface and transports it away from the product stream.

- At a designated discharge point, the metal contaminants are released from the belt and collected in a disposal bin or chute.

- This automatic cleaning process eliminates the need for manual intervention, reducing labor costs and downtime.

Optimized for High-Volume Applications

- Designed for continuous operation in high-speed processing lines, the RBM effectively handles large material volumes without compromising separation efficiency.

- The receiving belt mechanism ensures minimal product carryover, preventing metal reintroduction into the material flow.

- The system operates at conveyor speeds of up to 250 feet per minute, making it ideal for heavy-duty applications.

System Benefits

- Reliable Tramp Metal Removal – Protects crushers, grinders, and other processing equipment from costly damage.

- Reduced Maintenance & Downtime – The self-cleaning design minimizes the need for operator involvement, ensuring continuous operation.

- Durable & Long-Lasting Construction – Available in standard and abrasion-resistant models, featuring dust-tight enclosures for enhanced durability in industrial environments.

- Easy Integration – Compact, modular design allows seamless retrofitting into existing conveyor systems.

- Customizable Options – Configurable for various suspension heights, belt speeds, and material handling requirements.

MPI’s Self-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet is an industry-leading solution for automated tramp metal separation, ensuring maximum equipment protection, operational efficiency, and product purity.

Self-Clean Suspended Receiving Belt Magnet/Cross Belt Separator Specification Table

US Customary Units

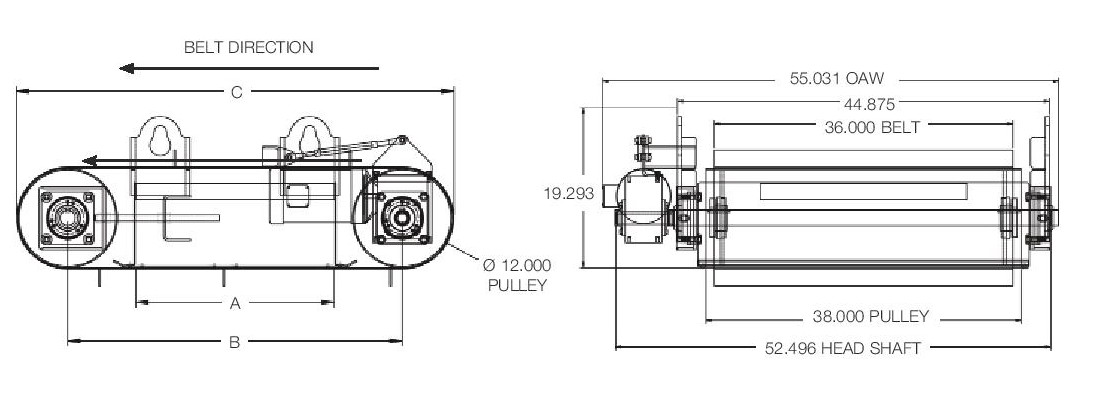

| CROSS BELT MODEL # | (A) OVERALL LENGTH (IN.) | (B) CENTER-TO-CENTER OF PULLEYS (IN.) | (C) FRAME LENGTH (IN.) | MOTOR HORSEPOWER | APPROX. WEIGHT (LBS.) |

|---|---|---|---|---|---|

| CBS-124 | 24 | 40 | 53 | 1 | 1678 |

| CBS-130 | 30 | 46 | 59 | 1 | 2147 |

| CBS-136 | 36 | 52 | 65 | 1 | 2726 |

| CBS-142 | 42 | 58 | 71 | 1 | 3462 |

| CBS-148 | 48 | 64 | 77 | 1 | 4397 |

Self-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet/Cross Belt Separator Installations

Self-Clean Suspended Receiving Belt Magnet with Extra-Wide Belt for Wood & Pulp Industry Pre-Grinding Process

Self-Clean Suspended Receiving Belt Magnet for Recycling Shredded Materials, Electronic Waste, and Other Recyclables

Self-Clean Suspended Receiving Belt Magnet Designed for Processing Ores and Crushed Stone in Mining