Simple and Automatic Fluid Cleaning

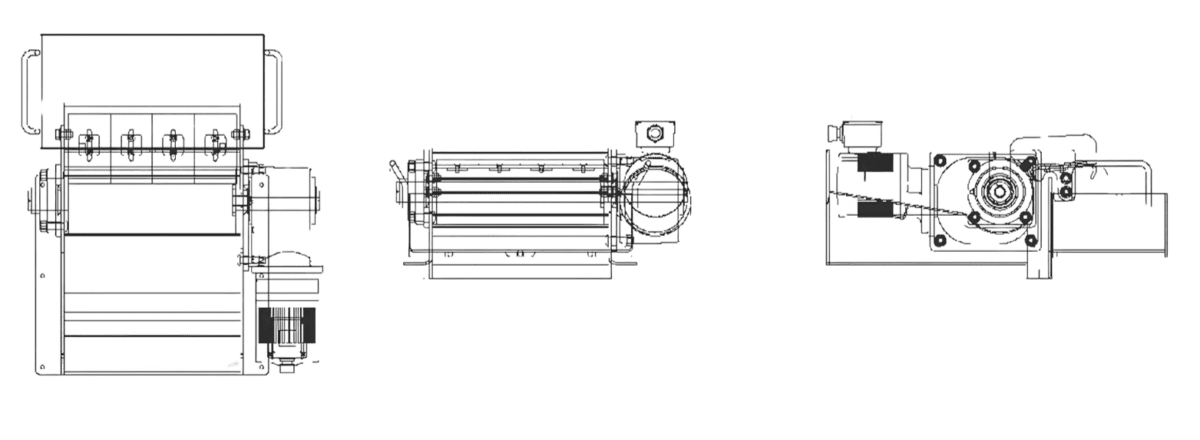

MPI's Coolant Cleaner is a magnetic separator designed for continuous cleaning, effectively eliminating ferrous materials from the coolant flow and collecting them in a disposal bin. This CC-series cleaner is perfect for production processes involving ferrous materials on cutting and grinding machine tools, and it operates efficiently with both water-based coolants and straight cutting oils. It is both cost-effective and durable, prolonging the life of machine tools and coolant. Additionally, it enhances productivity by reducing downtime associated with coolant replacement.

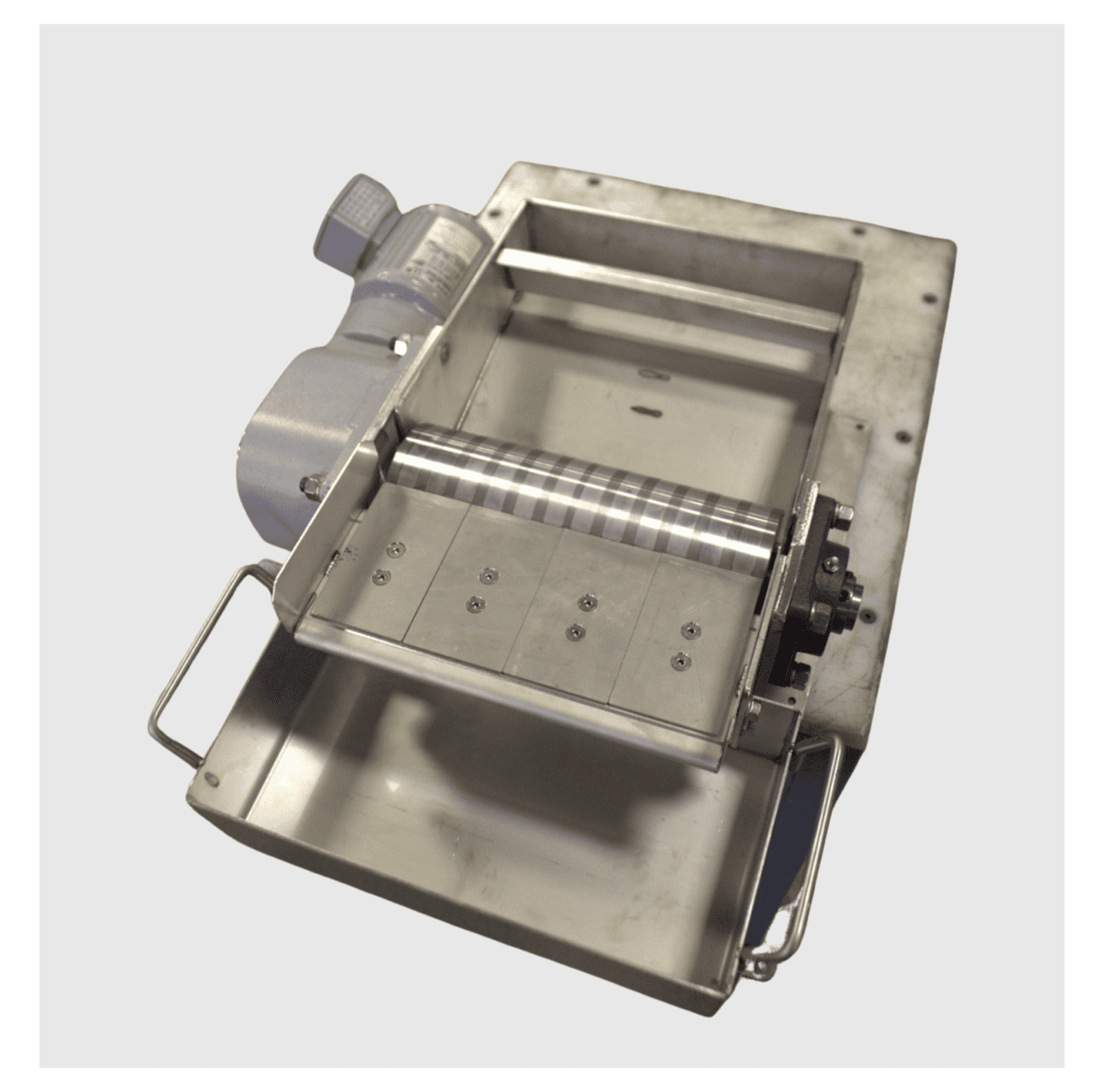

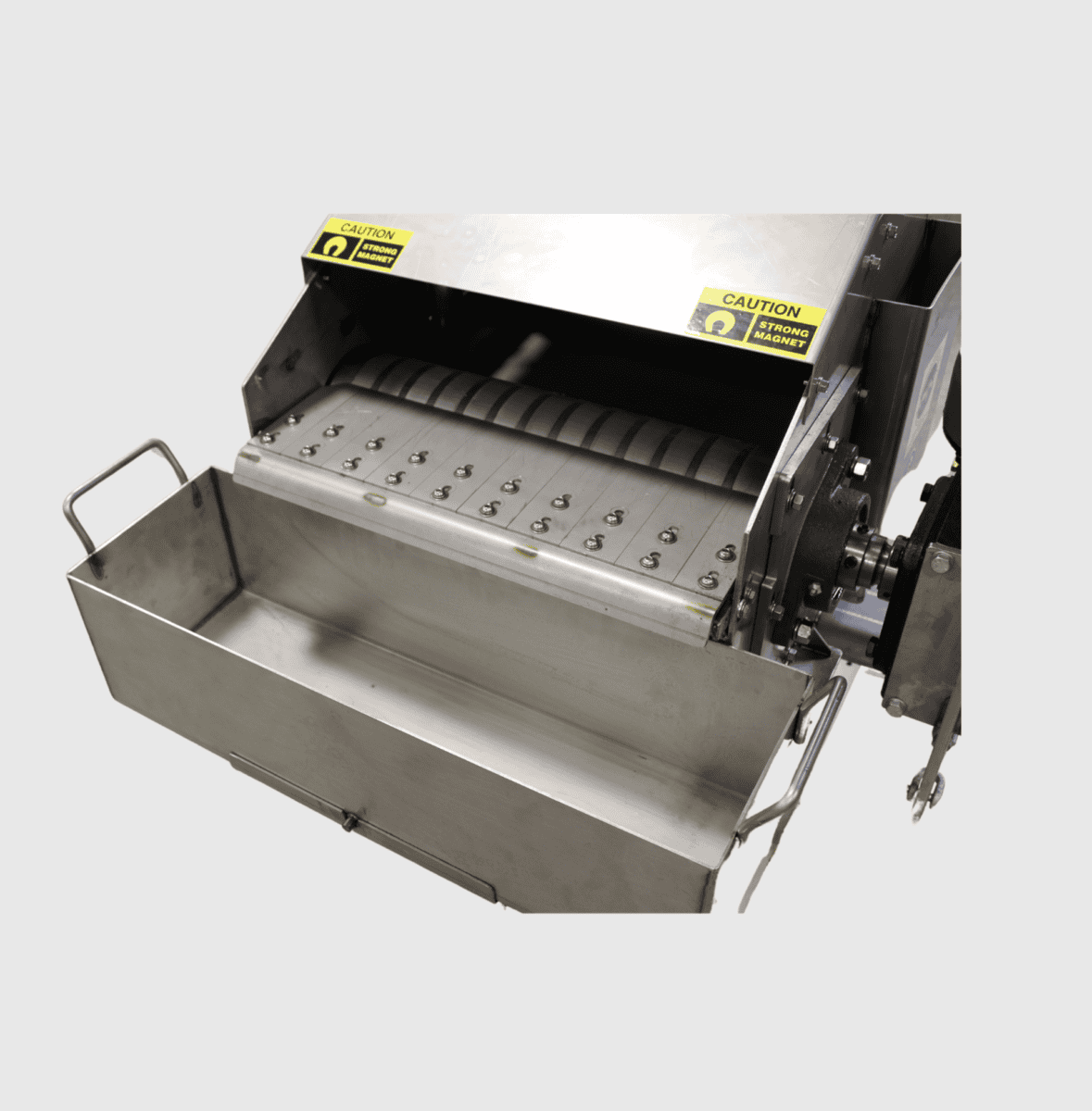

Featuring an automatic cleaning mechanism, the robust Ceramic 8 magnet drum is partially submerged in the coolant flow, ensuring that all liquid interacts with its high-intensity magnetic field. Ferrous contaminants are attracted to the rotating drum, where they are continuously removed by a specially designed scraper. As the contaminants are moved along the scraper, they are compressed, allowing excess liquid to drain back into the tank and leaving the solids nearly dry.

The Coolant Cleaner Magnet is specifically designed to eliminate ferrous contaminants from industrial coolants, lubricants, and various fluids. By extracting magnetic particles, it contributes to cleaner fluids, thereby enhancing machinery performance and improving product quality.

Benefits of the Coolant Cleaner From Magnetic Products, Inc

-

Extended Equipment Life

Reduces wear on machinery components by eliminating abrasive contaminants.

-

Enhanced Fluid Purity & Efficient Filtration

Captures ferrous contaminants before they can affect machine performance. Effectively removes ferrous particles, ensuring cleaner fluids.

-

Continuous, Automatic Operation

Reduces manual maintenance and downtime.

-

Cost-Effective & Durable

Simple and quick cleaning process reduces downtime and ensures operational efficiency.

-

Versatile & Scalable

Works as a standalone unit or as part of a multi-stage filtration system.

-

Eco-Friendly Design

Maximizes coolant reuse and minimizes waste disposal.

Coolant Cleaner Product Details

MPI’s Coolant Cleaner Magnet is an advanced, continuous-cleaning magnetic separator designed to remove ferrous contaminants from coolant or cutting fluids efficiently. Using robust Ceramic eight magnetic material in its drum core, this system ensures high-performance filtration, extending the life of machine tools and improving overall productivity.

Step-by-Step Process:

Magnetic Filtration Begins

- The Coolant Cleaner’s rotating drum is partially submerged in the liquid coolant, allowing the contaminated fluid to flow across its magnetic surface.

- The strong magnetic field penetrates the coolant, attracting ferrous particles as the liquid moves through the system.

Ferrous Contaminants Captured

- Any ferrous material in the coolant is magnetically drawn to the drum’s surface.

- The contaminants remain securely attached to the drum as it rotates, effectively separating them from the liquid.

Continuous Cleaning Mechanism

- A precision-engineered scraper blade continuously removes the accumulated ferrous debris from the rotating drum.

- As the material is pushed along the scraper, it is compressed, squeezing out excess liquid.

- The reclaimed liquid drains back into the coolant tank, ensuring minimal fluid loss.

Dry Collection & Disposal

- The compressed, nearly dry solid contaminants are directed into a disposal bin, reducing waste volume and simplifying cleanup.

- The dry material can then be easily discarded or recycled, depending on facility procedures.

Seamless Integration & Efficiency

- The CC-series separator can be used as a standalone filtration unit or integrated with additional purification systems for enhanced filtration performance.

- Designed for continuous operation, it minimizes downtime and maintenance by keeping coolant-free of ferrous contaminants.

- Compatible with water-based coolants and straight-cutting oils, the system ensures a cleaner work environment and prolongs the life of machine tools.

MPI’s Coolant Cleaner Magnet is an essential solution for machining processes that generate ferrous debris. It ensures cleaner coolant, improved tool longevity, and optimized manufacturing efficiency.

Coolant Cleaner Specification Table

US Customary Units

| MODEL # | WATER SOLUBLE CONTAMINATION APPROX. CAPACITIES/GPM (LIGHT/HEAVY) | OIL 100 SSU CONTAMINATION APPROX. CAPACITIES/GPM (LIGHT/HEAVY) | MAGNETIC DRUM DIAMETER (IN.) | MAGNETIC DRUM WIDTH (IN.) | APPROX. WEIGHT (LBS.) |

|---|---|---|---|---|---|

| CC-06 | 20 / 15 | 15/10 | 4.625 | 6 | 65 |

| CC-12 | 40/35 | 25/20 | 4.625 | 12 | 135 |

| CC-18 | 65/50 | 40/30 | 4.625 | 18 | 175 |

| CC-24 | 85/70 | 50/40 | 4.625 | 24 | 225 |

Coolant Cleaner Installations & Variations

MPI Magnetic Coolant Cleaner Used in Machining Process to Enhanced Surface Finish

Coolant Cleaner Magnet Installed to Capture Metal Chips Flushed Away from Cutting Zone

Magnetic Coolant Cleaner Installed in High-Volume Facility that Specializes in Turning, Milling, Drilling, and Grinding