Excellent Ferrous Separation Performance

The MPI Pro-Tector is a dual-stage metal separation solution that unites the robust magnetic separation capabilities of a rare-earth magnet with the thorough metal detection offered by an advanced electronic sensor, all housed in a compact, inline unit. This integrated system is tailored for gravity-fed, free-flowing materials like powders, granules, and flakes, providing exceptional protection against both ferrous and non-ferrous contaminants. The Pro-Tector is perfectly suited for the food, pharmaceutical, plastics, and chemical processing industries, enhancing product purity, protecting downstream equipment, and ensuring compliance with rigorous quality and regulatory standards. Its space-efficient design facilitates installation while maximizing detection coverage across all metal types.

The Pro-Tector systems merge outstanding ferrous separation efficiency of a magnet with the detection capabilities for non-ferrous and stainless metals, all encapsulated in a single compact unit. With this combination system, users can achieve enhanced separation performance while minimizing product loss that typically occurs with metal detection alone. It integrates a magnetic separator and a metal detector into one streamlined unit. The Pro-Tector enables rapid and easy removal of metals from the product stream and fits comfortably in the tight spaces often found in production facilities. It is available for gravity, liquid, and pneumatic conveying systems.

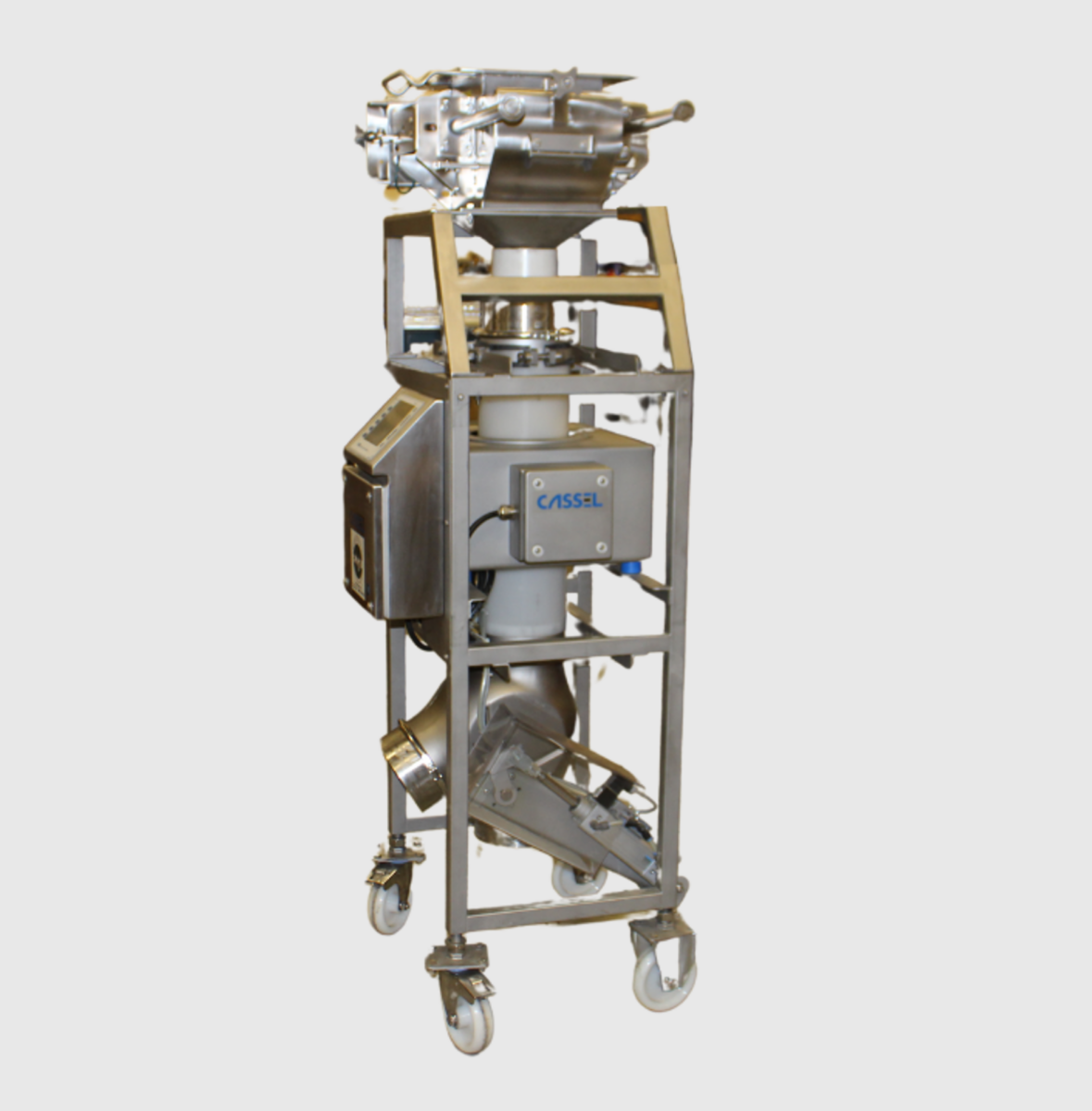

The Pro-Tector efficiently blends the ease of a magnetic separator with the dependability of a metal detector in a single compact unit. This innovative system ensures quick and effortless removal of metals from the product stream, and its size is designed to fit into the confined spaces typical of production environments. Designed for use in gravity-feed systems to detect metal contaminants in continuously flowing granules or powders, such as sugar, flour, cornmeal, or spices, the Pro-Tector features an integrated drawer magnet that maximizes magnetic separation of contaminants. Product first passes through the drawer magnet, located at the top of the unit, before the ferrous-free product continues through a gravity-feed metal detector. The integrated drawer magnet utilizes two layers of rare-earth magnetic tubes for optimal magnetic separation of metal contaminants, and its quick-clean function allows operators to clean the unit in under ten seconds. Highly reliable and user-friendly, the Pro-Tector’s integrated metal detector boasts a straightforward operating system that guides users efficiently through setup and operation.

Benefits of the Pro-Tector From Magnetic Products, Inc

-

Integrated Magnet and Metal Detector System

Combining magnetic separation and electronic metal detection in a single housing reduces equipment footprint and installation complexity.

-

High-Efficiency Rare Earth Magnet

Captures ferrous and weakly magnetic contaminants like rust, scale, and wear particles before they reach the detector, improving performance and prolonging system life.

-

Advanced Digital Metal Detection

Detects non-ferrous and stainless-steel particles using multi-frequency technology, ensuring comprehensive inspection of gravity-fed product streams.

-

Compact, Space-Saving Design

Fits easily into tight vertical drops or retrofit applications, making it ideal for facilities with limited line space.

-

Fast-Acting Reject Mechanism

When contamination is detected, an integrated reject flap or diverter instantly removes the affected product, minimizing waste and downtime.

-

Hygienic Stainless-Steel Construction

Built for cleanability and durability with smooth, food-grade surfaces and IP-rated options for washdown environments. USDA-Certified Drawer Magnet Option.

-

Easy Installation and Maintenance

Supplied with standard flange or clamp connections for drop-in integration; tool-free access simplifies cleaning and inspection.

-

Supports HACCP and GFSI Compliance

Metal detection and magnet verification can be incorporated into critical control points (CCPs) for regulated quality programs.

Pro-Tector Product Details

The MPI Pro-Tector operates in gravity-fed vertical pipelines where bulk materials flow freely. As the product enters the unit, it first passes over a high-intensity rare earth magnetic plate or cartridge. This magnetic element attracts and retains ferrous particles—including small tramp iron, weld slag, or fine wear debris—effectively removing them from the product stream.

The remaining material then immediately flows through a digital metal detection coil. This sensor scans for residual metal contaminants, including non-ferrous (aluminum, brass) and stainless-steel particles that the magnet cannot capture. If contamination is detected, the control unit activates a fast-acting reject mechanism (typically a pneumatic flap or chute), diverting the contaminated product to a separate container while allowing clean product to pass through.

By removing magnetic and non-magnetic contaminants in a single unit, the Pro-Tector significantly improves process efficiency, product quality, and equipment protection—all while simplifying installation and maintenance compared to separate systems.

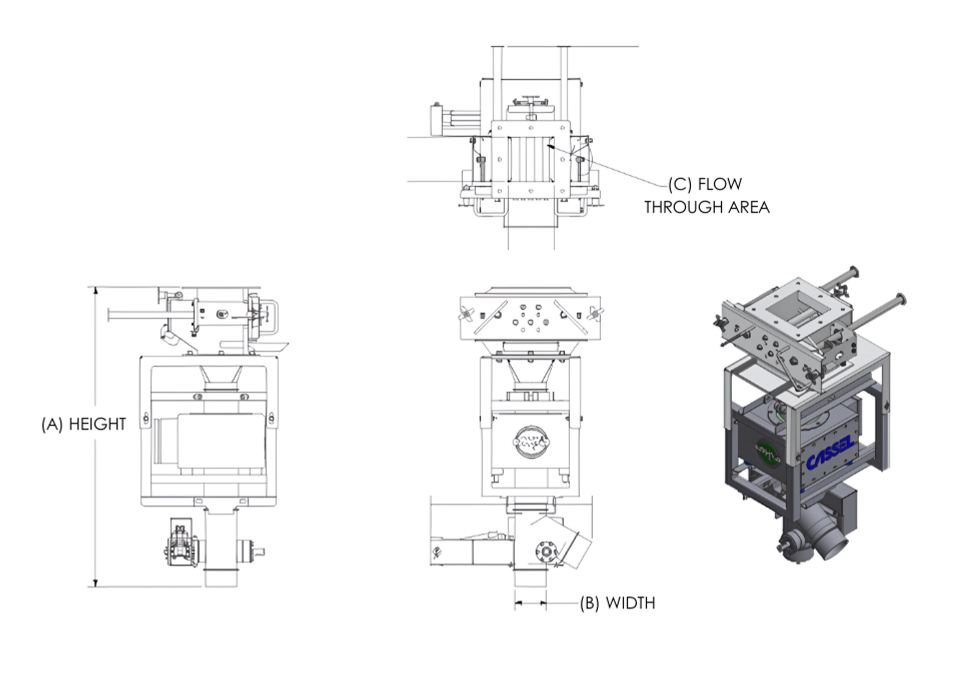

Pro-Tector Specification Table

US Customary Units

| PRO-TECTOR MODEL # | (A) OVERALL HEIGHT W/ REJECT(IN.) | DMU FLOW RATE: CU FT./HR. : GAL./HR. | (B) PIPE DIAMETER (IN.) | (C) FLOW THROUGH AREA (IN.) | SENSITIVITY FROM FE | DRAWER MAGNET (DMU) MODEL # | GF MODEL # |

|---|---|---|---|---|---|---|---|

| PRO-100 | 39.162 | 300 : 2,244 | 3.93 | 36x36 | <0.5 | DMU-206-QC | GF-100 |

| PRO-150 | 49.004 | 600 : 4,488 | 5.90 | 64x64 | <0.6 | DMU-208-QC | GF-150 |

| PRO-200 | 63.402 | 1350 : 10,098 | 7.87 | 100x100 | <1.2 | DMU-210-QC | GF-200 |

Pro-Tector Installations & Variations

Pro-Tector Designed for Gravity-Feed Pipes in Sugar Processing Application

Pro-Tector Designed for Continuous-Flowing Granules in Food Processing

Pro-Tector Specified for USDA Hygienic Application in Tight, Compact Facility Location