Highest Performance Metal Detection

MPI’s Pharma Metal Detector (PH) is an ultra-high sensitivity inspection system specifically engineered for the rigorous demands of pharmaceutical and nutraceutical tablet and capsule production. Designed for seamless installation at the discharge point of tablet presses and de-dusting units, the PH model provides an essential safeguard against metal contamination, ensuring that only clean, compliant product moves to the following processing or packaging stage.

Its compact, space-efficient design is ideal for cleanrooms and integration into existing equipment setups, making it perfect for new installations and retrofits. Utilizing advanced detection technology, the PH can identify sub-millimeter ferrous, non-ferrous, and stainless-steel contaminants with exceptional precision, far exceeding standard detection thresholds.

Crafted with a hygienic, GMP-compliant stainless-steel housing and FDA-accepted contact materials, the system supports easy cleaning and validation. Its high-speed, non-disruptive reject mechanism gently removes contaminated tablets or capsules without interrupting product flow, preserving product integrity and minimizing waste.

With built-in compatibility for 21 CFR Part 11 electronic records, secure user access, and integration with audit-ready software like SharkNet®, the PH system meets the strict regulatory requirements of pharmaceutical manufacturing environments. It is a reliable and efficient Critical Control Point (CCP) in HACCP and GMP-based quality systems, enhancing operational safety, data traceability, and product quality assurance in high-throughput, hygiene-critical environments.

Benefits of the Pharma Metal Detector (PH) From Magnetic Products, Inc

-

Ultra-High Sensitivity for Tiny Particles

Detects metal contaminants as small as 0.25 mm in stainless steel, ideal for ensuring the purity of tablets, capsules, and gel caps.

-

Compact, Space-Saving Design

Fits directly under tablet presses or de-dusters, maximizing production space without compromising detection coverage.

-

GMP-Compliant Construction

Built with FDA-approved materials, crevice-free stainless-steel housing, and a sanitary finish to meet strict pharmaceutical manufacturing standards.

-

Fast, Safe Reject System

Integrated pneumatic reject mechanism gently removes contaminated tablets or capsules without damaging product or interrupting flow.

-

21 CFR Part 11-Ready Electronics

Compatible with advanced control systems like MetalShark® 2 and SharkNet® for electronic audit trails, secure access control, and validation tracking.

-

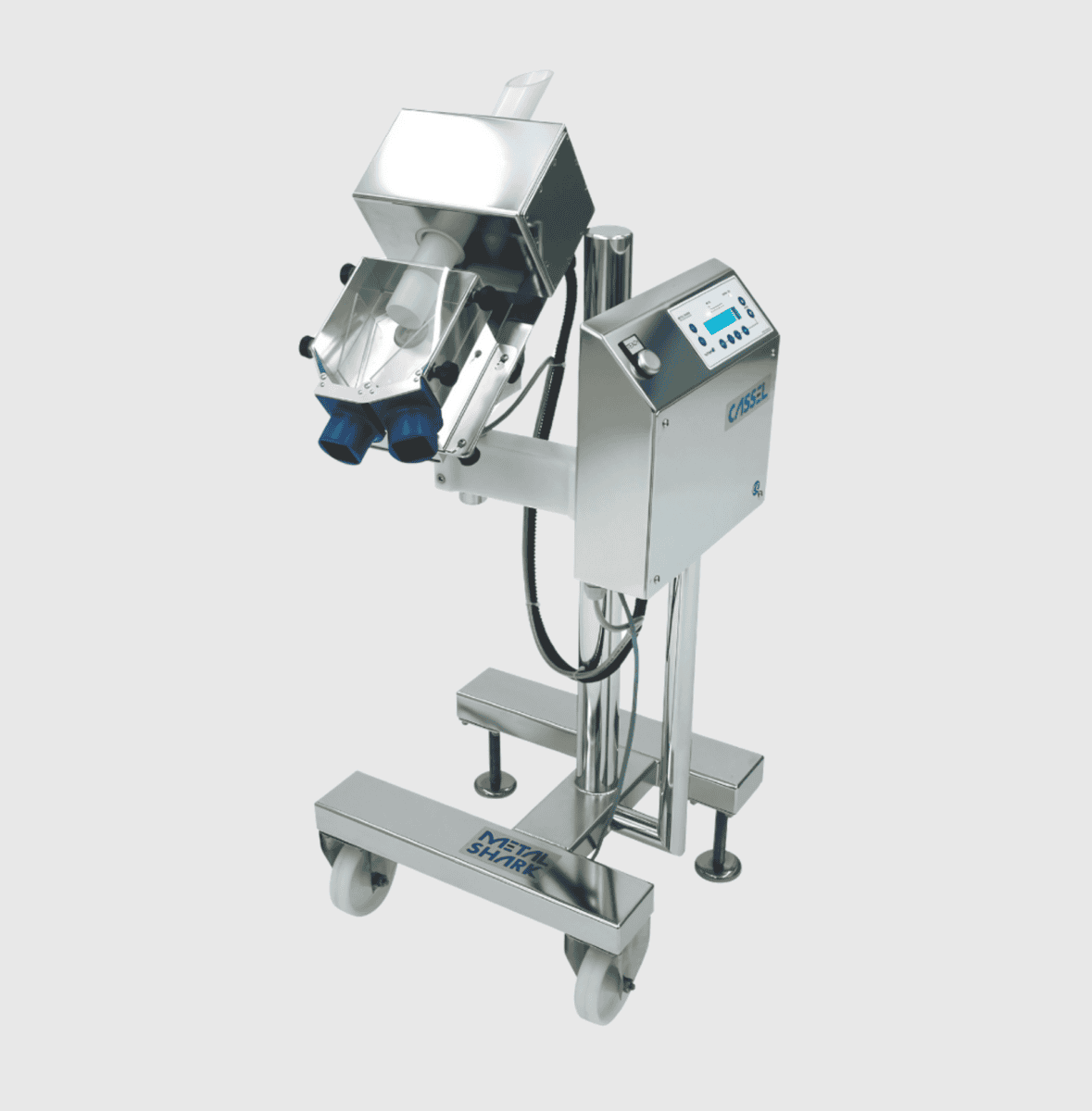

Tool-Free Disassembly for Cleaning

Quick-release components allow for fast, tool-free teardown and cleaning, reducing downtime and simplifying product changeovers.

-

Validation Support & Compliance Features

Includes test sample ports, reject confirmation sensors, and performance log capability for QA testing, audits, and third-party certification.

-

Multi-Product Memory & Auto-Learn Function

Stores multiple product profiles and quickly adapts to different shapes, sizes, or coatings without recalibration.

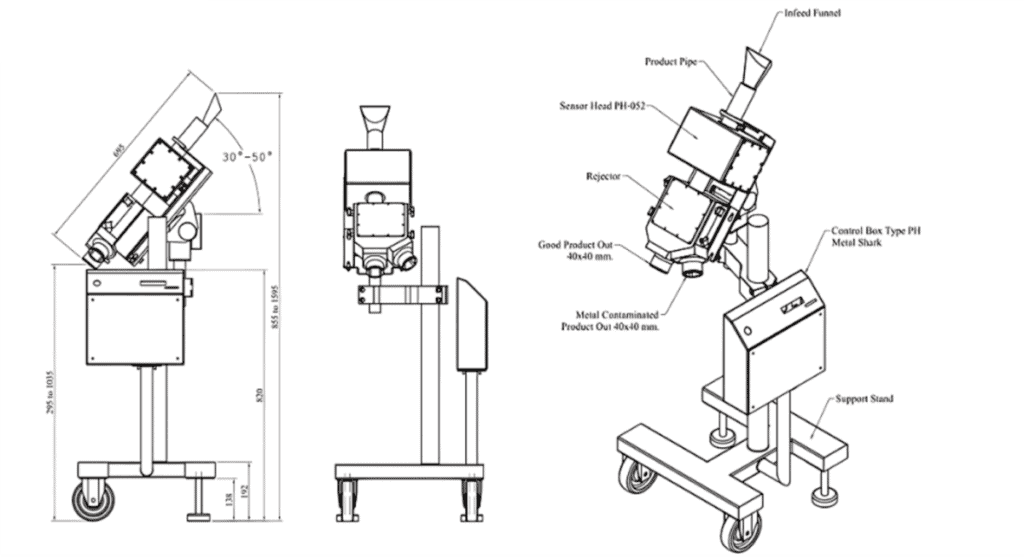

Pharma Metal Detector (PH) Product Details

The MPI Pharma Metal Detector (PH) is installed directly at the outlet of a tablet press or de-duster. As tablets or capsules are discharged via gravity, they pass through a precisely calibrated circular detection coil. This ring-shaped sensor generates an electromagnetic field that monitors every product passing through.

When a metal particle—ferrous, non-ferrous, or stainless steel—enters the detection zone, it disturbs the field. This triggers the control system, which instantly activates a high-speed pneumatic reject flap or diverter to remove the contaminated product into a secure reject container gently.

The system logs each event and can be configured to stop the machine or alert operators if multiple rejections occur. With its fast cycle time and high detection accuracy, the PH detector ensures that only metal-free products continue downstream for coating, packaging, or bottling.

Pharma Metal Detector (PH) Installations & Variations

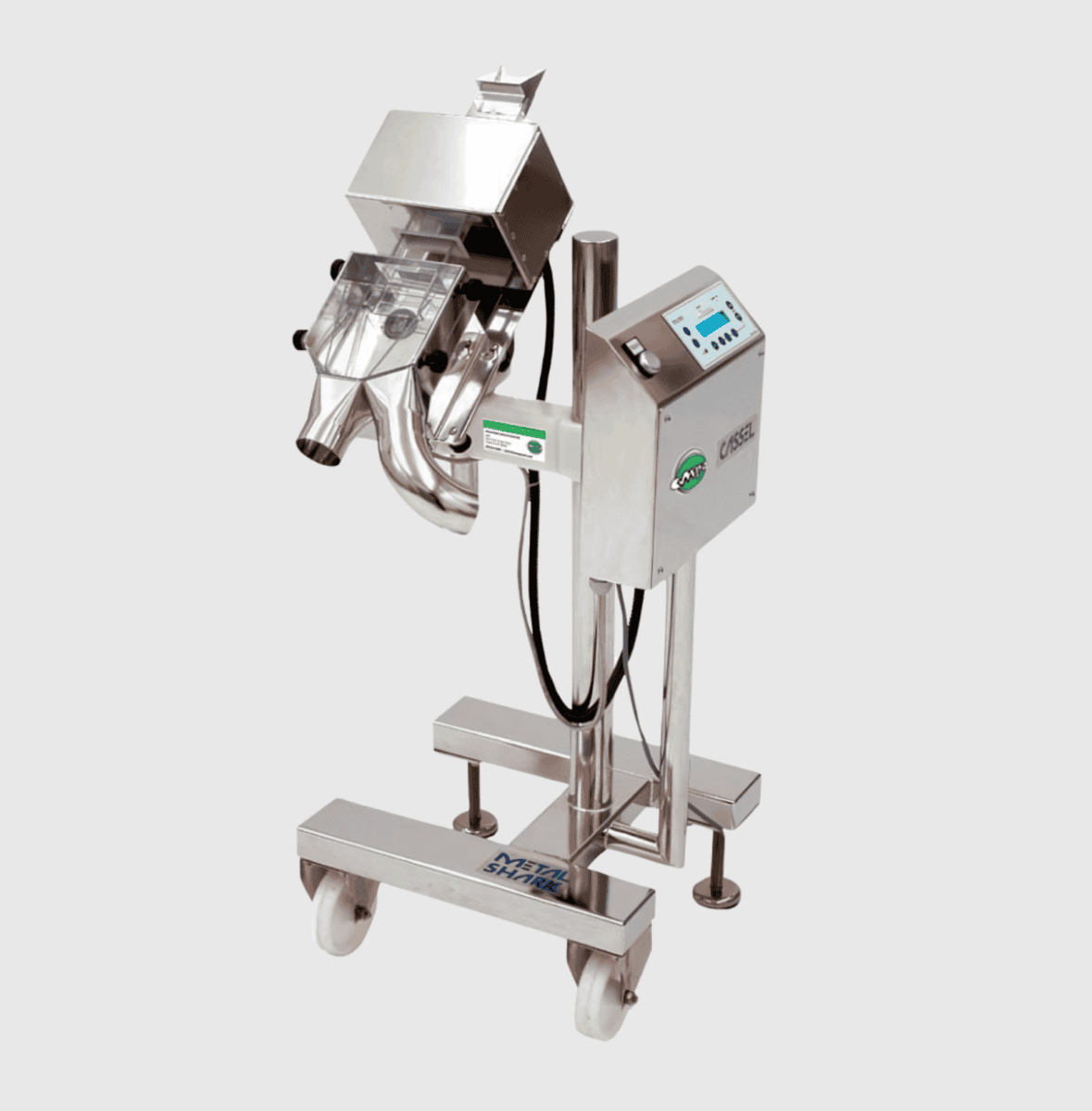

Pharma Metal Detector (PH) for Capsule Production

METAL SHARK© PH Control Box Digital Signal Processor

Pharma Metal Detector (PH) With Toolless Reject Disassemble to Prevent Tablet Damage