Reduce Contamination Risk

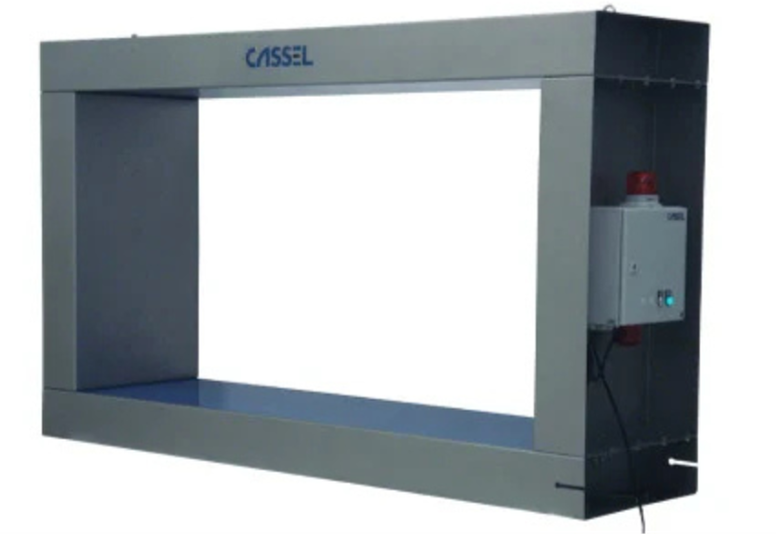

MPI’s Tunnel (TU) Metal Detector is a high-sensitivity, industrial-grade system that detects metal contaminants in bulk materials conveyed on belts. Ideal for use in recycling, wood, plastics, textile, and food processing operations, the TU model provides reliable inline inspection of both the top and bottom of conveyed products, ensuring maximum coverage for tramp metal detection. Its robust rectangular design accommodates a wide range of product sizes and conveyor widths, and its rugged construction makes it suitable for challenging environments with dust, vibration, and variable product flow. With fast response times, multi-channel signal processing, and seamless integration with belt systems, the Tunnel Metal Detector helps protect downstream equipment, maintain product quality, and support regulatory compliance.

Benefits of the Tunnel (TU) Metal Detector From Magnetic Products, Inc

-

Full-Belt Detection Coverage

Detects ferrous, non-ferrous, and stainless-steel contaminants across the entire width and height of the conveyor load—ideal for inspecting uneven or bulk materials.

-

Rugged, Industrial-Grade Construction

The TU detector is engineered with heavy-duty steel or stainless-steel housing and withstands harsh production environments including dust, moisture, and mechanical vibration.

-

Customizable Aperture Sizes

Available in various standard and custom sizes to accommodate varying belt widths, product heights, and installation requirements.

-

Advanced Signal Processing & Filtering

Digital electronics with multi-frequency and noise-filtering technology minimize false triggers caused by vibrations, product effects, or environmental interference.

-

High-Speed Detection & Response

Rapid reaction time enables detection of small contaminants even at high conveyor speeds, reducing the risk of downstream equipment damage.

-

Flexible Integration with Conveyors

It easily installs above, below, or around existing belt conveyor systems and includes mounting kits or frame support options as needed.

-

User-Friendly Control System

A touchscreen interface with product memory, error logging, and reject signal output simplifies setup and operation for plant personnel.

-

Compliance Support for Safety & Quality

Functions as a Critical Control Point (CCP) in compliance with HACCP, ISO, or industry-specific quality management systems.

Tunnel (TU) Metal Detector Product Details

MPI’s Tunnel (TU) Metal Detector is mounted around a conveyor belt carrying bulk or packaged product. As the product passes through the rectangular tunnel-shaped aperture, it is exposed to a precisely balanced electromagnetic field generated by the transmitter and receiver coils.

When a piece of metal contaminant—ferrous, non-ferrous, or stainless steel—passes through this field, it causes a disturbance detected by the system’s sensitive electronics. This triggers a signal that activates an alert or initiates a reject sequence downstream (e.g., stopping the conveyor, activating a diverter, or tagging the contaminated batch for manual inspection).

The system can be installed above the belt (over-belt detection), below it (under-belt), or fully encased around the conveyor. In some setups, dual coil systems are used to ensure coverage of both the top and bottom of large, uneven loads. Detection parameters are programmable and adaptive to different product types, densities, and line speeds, ensuring reliable operation and minimal false rejects.

Tunnel (TU) Metal Detector Specification Table

| MD-TU COMPONENT FEATURE | METAL DETECTING FOR CONVEYOR INSTALLATIONS |

|---|---|

| Installation | Conveyor, typical horizontal, but each angle is applicable. Sensor head able to divide: No belt cut required. |

| Sensing Width | 200 – 4000 mm (4 in–13,2 ft) |

| Metal Free Zone (before & after detector) | Fix metal = 100 mm Moving/vibrating metal = 1.5 x aperture height |

| Degree of Protection | (Optional IP 65, Optional IP 67) |

| Sensor Head | Stainless-steel housing |

| Controller | METAL SHARK® for wall mounting, optional attached to sensor (available if tunnel height 400 mm or higher) *W380 option for SHARK controller digital control box for rough industrial environment, wall installation. 3 m sensor linkable, power supply 85–264V/50 60Hz. Housing size 380 x 380 x 210 mm. |

Tunnel (TU) Metal Detector Installations & Variations

Tunnel (TU) Detector for Wood Processing in Landscaping Application

Tunnel (TU) Detector for Pulp Processing in Paper Production

Tunnel (TU) Detector for Plant Particulate Processing for Herbal Supplements