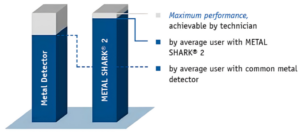

Industry Benchmark for Performance

The MPI Metal Shark® 2 Controller is a next-generation digital control unit that powers MPI’s advanced metal detection systems with unmatched precision, flexibility, and ease of use. Designed for demanding industrial environments—from food and pharmaceutical production to plastics and recycling—the Metal Shark® 2 leverages a powerful digital signal processor, intelligent noise filtering, and adaptive product compensation algorithms to deliver ultra-reliable metal detection across various applications.

Its intuitive, multilingual touchscreen interface simplifies setup, while its multi-frequency capability ensures optimized detection of ferrous, non-ferrous, and stainless-steel contaminants in dry and wet product environments. With built-in connectivity, integrated diagnostics, and compatibility with SharkNet® software, the Metal Shark® 2 enables full traceability, audit readiness, and real-time quality control from a centralized platform.

Benefits of the Metal Shark 2 Controller From Magnetic Products, Inc

-

Multi-Frequency Digital Processing

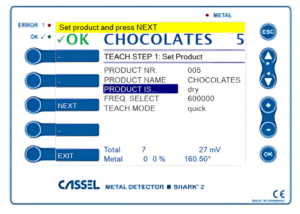

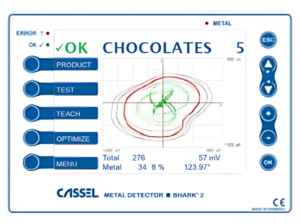

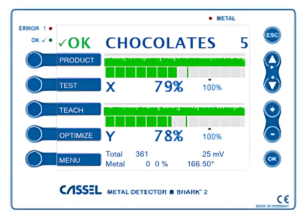

It automatically selects the optimal frequency for each product, ensuring highly sensitive and stable detection of all metal types—even in products with high moisture, salt, or temperature variation.

-

Advanced Noise Filtering & Compensation

It is equipped with digital noise filters, balance control, and auto-compensation for challenging environments such as vibrating conveyors, high-load applications, or dense product flows.

-

High-Capacity Product Memory

Stores up to 120 product profiles with Teach Assistant support, enabling fast product changeover and repeatable, validated performance across multiple lines or SKUs.

-

User-Friendly Touchscreen Interface

Intuitive color display with graphical feedback, auto-setup wizards, multilingual support, and password protection for easy operation and secure access control.

-

Real-Time Diagnostics & Auto-Self Test

Continuously monitors system performance, executes automatic self-checks, and logs errors for proactive maintenance and quality assurance.

-

Flexible I/O & Integration

Includes configurable 24 VDC inputs/outputs for connection to encoders, reject mechanisms, alarms, and conveyor logic, supporting seamless integration into automated lines.

-

SharkNet® Connectivity for Compliance

Optional SharkNet® software enables remote monitoring, report generation, validation tracking, and 21 CFR Part 11 audit trail compliance for regulated industries.

-

Robust & Scalable for Any Application

Supports a wide range of detector coil types (gravity, conveyor, pipeline, etc.) and is rated for use in standard, washdown, or hygienic environments with IP65+ enclosures.

Metal Shark 2 Controller Product Details

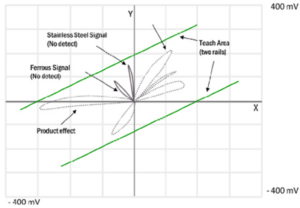

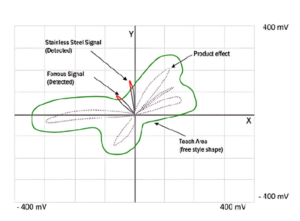

The Metal Shark® 2 Controller is the intelligence hub of MPI’s metal detection systems. It interfaces with detection coils mounted in gravity, belt, or pipeline configurations and manages the electromagnetic field that scans for metallic contaminants.

As product flows through the coil, the controller continuously monitors for disturbances in the electromagnetic field. The controller’s signal processor digitizes and analyzes these disturbances, applying noise filtering, balance correction, and frequency optimization algorithms. A signal exceeding the calibrated threshold is classified as a contaminant event.

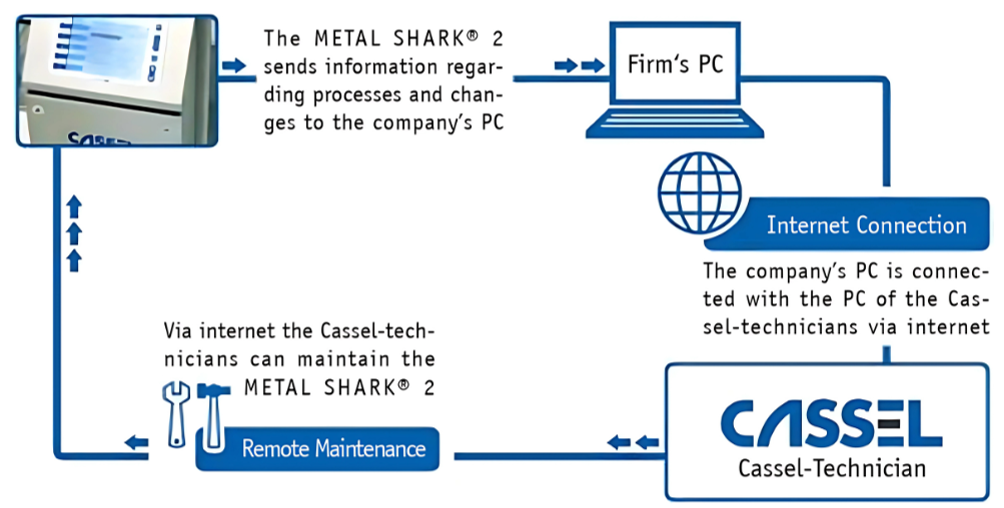

The controller then triggers one or more outputs—such as activating a reject mechanism, pausing the line, or issuing an alert—and logs the event. Operators can view the touchscreen's real-time system status, product data, and rejection logs. With SharkNet® connectivity, QA managers can monitor the system remotely, generate validation reports, and ensure full traceability across the facility.

Metal Shark 2 Controller Specification Table

US Customary Units

| METAL SHARK CONTROLLER FEATURE | METAL SHARK 2 SOFTWARE CAPABILITY |

|---|---|

| Technology | 4-Quadrant Technology |

| Display | 5.4" color screen |

| Frequencies | 1, 2 or 4 |

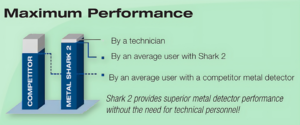

| Sensitivity | Normal user achieves 90% of metal detectors maximum performance without expert optimization |

| Teach | 3 to 7 samples |

| Interface | Excellent digital filters |

| Outputs | (2) Potential Free, (8) Programmable |

| Inputs | (8) Programmable |

| Language | Global languages available |

| Memory | Integrated flash for 1000 events |

| Parameter Backup | No |

| Number of Custom Products | 120 |

| Temperature | Standard: temp. -10°C to +40°C, rel. humidity 30 to 85% not condensing; Options: -40°C or +55°C |

| Power Input | 85-264 V AC, 50/60 Hz, 1P, self selecting |

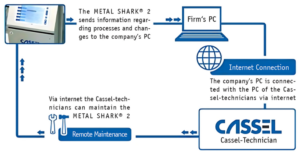

| Communication Interface | RS232, Ethernet and optional WLAN |

| Password Protection | 4 Levels |

| Control of Multiple Systems | No |

| Remote Maintenance | No |

| Auto Print of Reports | Yes, any report to network printer |

| Performance Validation Software | Yes |

Metal Shark 2 Controller Installations & Variations

SHARKNET® 2 Software to Monitor Real-Time Inspection Results and Activity from a Central Computer

SHARKNET® 2 Software Monitoring Traceability of All Operational Data

SHARKNET® 2 Software for Quick, Easy Viewing and Printing of HACCP Reports