Advanced Foreign Object Detection and Quality Control for Inline Packaging Lines

The MPI X-Ray Inspector for Packaged Products is a powerful non-invasive inspection system designed to detect non-metallic and metallic foreign objects, verify package integrity, and support inline quality assurance in high-speed production environments. Using cutting-edge dual-energy X-ray imaging, this system can identify various contaminants, including glass, bone, plastic, rubber, and metal, regardless of product type or packaging material.

Engineered for use in the food, pharmaceutical, nutraceutical, and consumer goods industries, MPI’s X-Ray Inspector goes beyond basic metal detection. It also performs critical quality checks such as missing product detection, mass estimation, fill level analysis, and component count verification, helping prevent product recalls and ensuring compliance with global safety standards.

Compact, washdown-ready, and fully customizable, the system seamlessly integrates into existing packaging lines to ensure product safety, brand protection, and regulatory compliance.

Benefits of the Packaged Product X-Ray Inspector From Magnetic Products, Inc

-

Broad-Spectrum Contaminant Detection

It detects not only metal but also glass, bone, ceramic, dense plastic, rubber, and stone—materials that standard metal detectors cannot identify. This ensures unmatched inspection versatility for diverse product and package types.

-

Advanced Dual-Energy X-Ray Imaging

Utilizes high-resolution, dual-energy X-ray imaging that enhances contrast and density discrimination, enabling more precise detection of low-density contaminants in complex or overlapping products.

-

Real-Time Image Analysis with Intelligent Algorithms

Powered by innovative imaging software that uses automated pattern recognition and contrast thresholds to identify anomalies or foreign objects, even in cluttered or variable-density packages.

-

Multi-Function Quality Assurance

In addition to contaminant detection, the system performs inline checks such as:

-

-

Missing or misaligned components

-

Overfill/underfill (mass estimation)

-

Crushed or broken contents

-

Seal integrity (for pouch and tray formats)

-

-

Hygienic, Washdown-Ready Construction

Made from 304 or 316 stainless steel with IP65+ enclosures and sloped surfaces, the system is built for harsh environments and supports full washdown and sanitation protocols in food and pharma facilities.

-

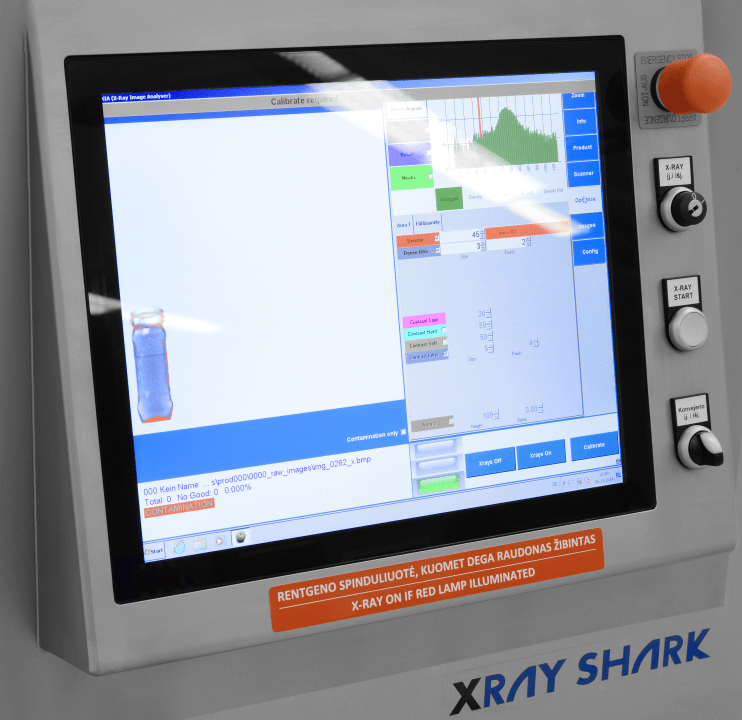

User-Friendly Touchscreen Interface

A high-resolution touchscreen HMI with recipe management, auto-teach setup, image storage, and event logging. Its multilingual support and intuitive layout make it operator-friendly across skill levels.

-

Automated Reject with Audit Trail Logging

Automatically removes contaminated or defective packages using air blast, diverter, pusher, or flap systems. Every event is logged for traceability with time stamps, images, and rejection reasons.

-

Supports Global Regulatory Compliance

Meets FDA, USDA, GFSI, IFS, BRCGS, and FSMA standards. Data storage, audit trail reporting, and secure access levels simplify compliance and third-party audit readiness.

Packaged Product X-Ray Inspector Product Details

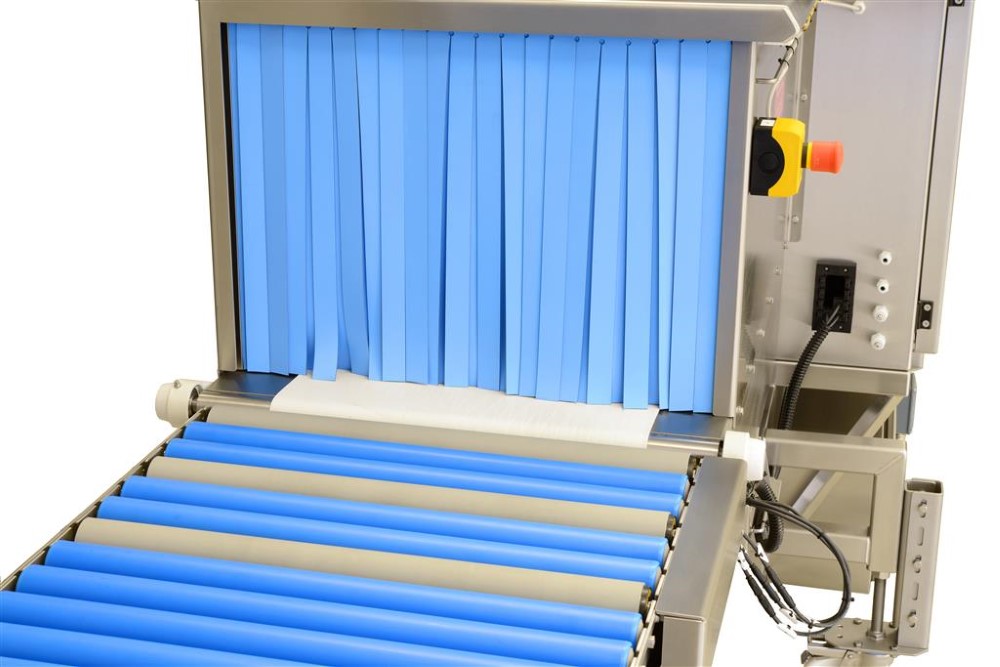

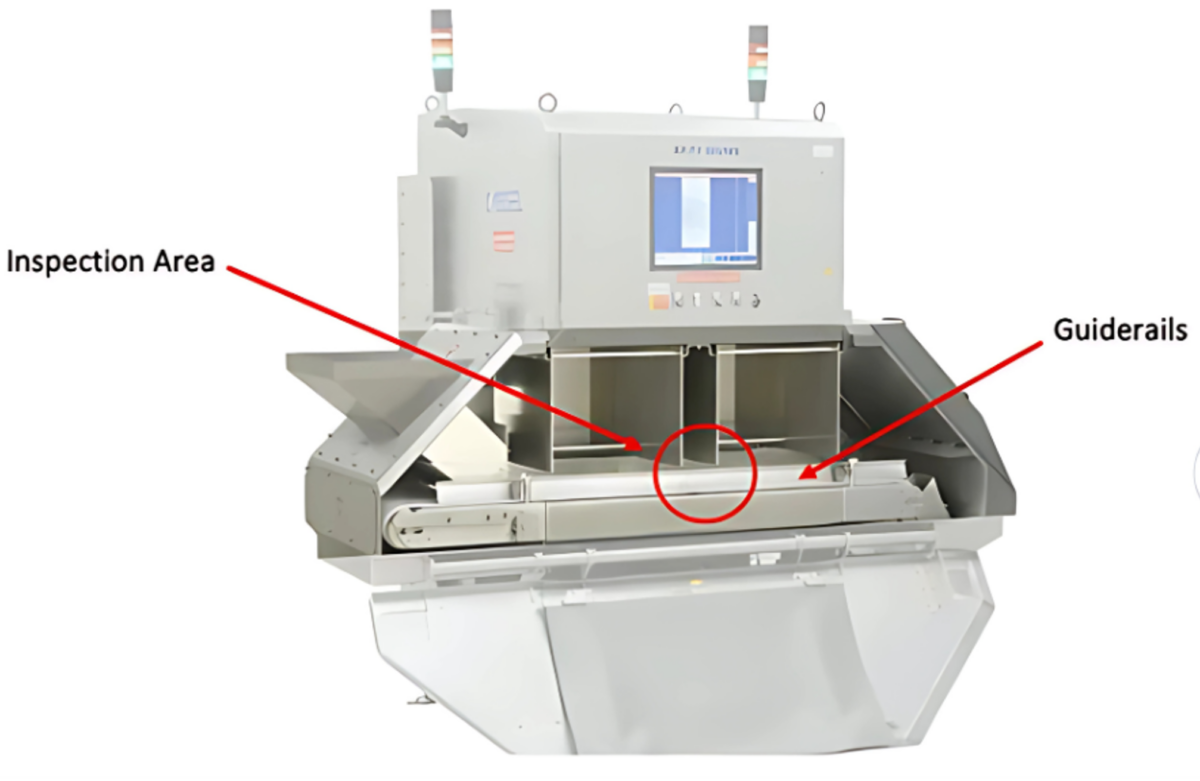

MPI’s X-Ray Inspector for Packaged Products operates by scanning sealed or open packages as they move through a conveyor belt system. The technology relies on X-rays' ability to pass through a product and detect differences in material density and atomic composition.

Product Enters Inspection Zone

Packages enter the X-ray tunnel on a conveyor. A photo eye or encoder may trigger image capture for each package.

X-Ray Beam and Image Acquisition

A controlled, low-dose X-ray beam is emitted from the generator and passes through the product. Dense or foreign objects absorb more radiation and appear darker in the image.

Image Processing and Anomaly Detection

A high-resolution detector captures the image and sends it to onboard software for analysis. Advanced algorithms compare the X-ray image to expected patterns, looking for:

- Unexpected shapes (foreign materials)

- Density changes (mass/voids)

- Product count or arrangement errors

- Internal defects or missing elements

Decision Logic and Reject Activation

If a contaminant or defect is detected:

- The system sends a signal to a configured reject mechanism (e.g., air blast, pusher)

- The defective product is diverted to a reject bin or lane for safe handling

Data Logging and QA Reporting

Each inspection is logged with images, timestamps, operator activity, and rejection cause. Reports can be exported or networked to a central QA database for traceability and compliance.

Packaged Product X-Ray Inspector Specification Table

US Customary Units

| MODEL FEATURE | XRAY SHARK® G20 | XRAY SHARK® G20+ | XRAY SHARK® G40 |

|---|---|---|---|

| X-RAY SOURCE | 1 pcs. low power x-ray generator, with max. 70 kV @ 2.0mA (140W), variable in voltage + current | 1 pcs. low power x-ray generator, each with max. 70 kV @ 2.0mA (140W), variable in voltage + current | 1 pcs. high power x-ray generator, each with max. 80 kV @ 4.5mA (360W), variable in voltage + current |

| COOLING | Integrated closed loop oil cooling system Optional: Additional device with active cooling (Aircon or Peltier) | Integrated closed loop oil cooling system Optional: Additional device with active cooling (Aircon or Peltier) | Integrated closed loop oil cooling system Optional: Additional device with active cooling (Aircon or Peltier) |

| SAFETY | X-ray emission max 1 µSv/h or less, at using all safety devices | X-ray emission max 1 µSv/h or less, at using all safety devices | X-ray emission max 1 µSv/h or less, at using all safety devices |

| DISPLAY | 15“ Color-TFT Touchscreen | 15“ Color-TFT Touchscreen | 15“ Color-TFT Touchscreen |

| MAX DIMENSIONS | 250x50 / 230x100 / 200x140 / 170x200 mm | 340x60 / 300x100 / 250x160 / 200x200 mm | 340x60 / 300x100 / 250x160 / 200x200 mm |

| PRODUCT MEMORY | 250 | 250 | 250 |

| CONVEYOR TYPE | PU belt conveyor, included | PU belt conveyor, included | PU belt conveyor, included |

| CONVEYOR SPEED | Max. 80 m/min (depends on application) | Max. 80 m/min (depends on application) | Max. 80 m/min (depends on application) |

| ENVIORNMENTAL CONDITIONS | 0 to +30 ° C, with relative humidity max 90% non-condensing With optional additional cooling device: 0 to +45 ° C | 0 to +30 ° C, with relative humidity max 90% non-condensing With optional additional cooling device: 0 to +45 ° C | 0 to +30 ° C, with relative humidity max 90% non-condensing With optional additional cooling device: 0 to +45 ° C |

| POWER SUPPLY | 230V 1 phase 50 to 60 Hz | 230V 1 phase 50 to 60 Hz | 230V 1 phase 50 to 60 Hz |

| POWER CONSUMPTION | 1,3 kW | 1,3 kW | 1,6 kW |

| DEGREE OF PROTECTION | Overall: IP42 (due to the required cooling air slots) With optional wet room package: overall IP54 and product tunnel IP66 | Overall: IP42 (due to the required cooling air slots) With optional wet room package: overall IP54 and product tunnel IP66 | Overall: IP42 (due to the required cooling air slots) With optional wet room package: overall IP54 and product tunnel IP66 |

| FALSE REJECT RATE | 1/5000 …. 1/10000 | 1/5000 …. 1/10000 | 1/5000 …. 1/10000 |

| WEIGHT | 470 kg | 540 kg | 610 kg |

| COMPRESSED AIR CONSUMPTION | Without pusher 0 (zero) liters / hour. With optional pusher system: less than 20 liters / hour | Without pusher 0 (zero) liters / hour. With optional pusher system: less than 20 liters / hour | Without pusher 0 (zero) liters / hour. With optional pusher system: less than 20 liters / hour |

| X-RAY DETECTOR RESOLUTION | Diode size 0.8 mm, optional 0.4 and 0.2 mm | Diode size 0.8 mm, optional 0.4 and 0.2 mm | Diode size 0.8 mm, optional 0.4 and 0.2 mm |

| OPERATING COSTS AT 2 SHIFTS | Circa 6.000 € / year (includes power supply and depreciation for X-ray tube replacement) | Circa 7.000 € / year (includes power supply and depreciation for X-ray tube replacement) | Circa 8.000 € / year (includes power supply and depreciation for X-ray tube replacement) |

| SUPPLIED TEST EQUIPMENT | Certified test cards with glass, ceramics, steel spheres in various diameter | Certified test cards with glass, ceramics, steel spheres in various diameter | Certified test cards with glass, ceramics, steel spheres in various diameter |

| INSPECTION FEATURES | Density, Hard Contrast, Soft Contrast, Masking Technology, SuperContrast, AutoEdge, Images AutoSave/Load, Multi Segment Inspection, Metal Can and Metal Foil inspection, Fill Level, Generator Energy by Product, Password protection | Density, Hard Contrast, Soft Contrast, Masking Technology, SuperContrast, AutoEdge, Images AutoSave/Load, Multi Segment Inspection, Metal Can and Metal Foil inspection, Fill Level, Generator Energy by Product, Password protection | Density, Hard Contrast, Soft Contrast, Masking Technology, SuperContrast, AutoEdge, Images AutoSave/Load, Multi Segment Inspection, Metal Can and Metal Foil inspection, Fill Level, Generator Energy by Product, Password protection |

| DATA TRANSFER AND REPORTING | USB, Ethernet, Sharknet Interface for auto reporting and auto recording, Internet Remote Maintenance | USB, Ethernet, Sharknet Interface for auto reporting and auto recording, Internet Remote Maintenance | USB, Ethernet, Sharknet Interface for auto reporting and auto recording, Internet Remote Maintenance |

| OTHER FEATURES | Sanitary stainless steel finish, Direct variable conveyor speed by product, Barcode Reader Interface, MultiCore CPU, Win XP OS | Sanitary stainless steel finish, Direct variable conveyor speed by product, Barcode Reader Interface, MultiCore CPU, Win XP OS | Sanitary stainless steel finish, Direct variable conveyor speed by product, Barcode Reader Interface, MultiCore CPU, Win XP OS |

| 24V IN/OUTPUTS | 8x programmable outputs (pusher, error, alarm, conveyor speed, others) 8x programmable inputs (photo sensor, air monitor, reject monitor, bin full, blockage sensor, others) | 8x programmable outputs (pusher, error, alarm, conveyor speed, others) 8x programmable inputs (photo sensor, air monitor, reject monitor, bin full, blockage sensor, others) | 8x programmable outputs (pusher, error, alarm, conveyor speed, others) 8x programmable inputs (photo sensor, air monitor, reject monitor, bin full, blockage sensor, others) |

| CERTIFICATES | CE, comply to German x-ray regulations, certified by TÜV | CE, comply to German x-ray regulations, certified by TÜV | CE, comply to German x-ray regulations, certified by TÜV |

| AVAILABLE ACCESSORIES | Radiometer, Sharknet Software, BRC Kit (British Retailer Compliance), Pusher Devices, Barcode Reader | Radiometer, Sharknet Software, BRC Kit (British Retailer Compliance), Pusher Devices, Barcode Reader | Radiometer, Sharknet Software, BRC Kit (British Retailer Compliance), Pusher Devices, Barcode Reader |

Compatibility Check - Packaged Product X-Ray Inspector Installations

Packaged Product X-Ray Inspector Used in Dairy Product Production

Packaged Product X-Ray Inspector for Ready-to-Eat Salads, Snacks, and Meal Kits

Packaged Product X-Ray Inspector for Blister Packs of Capsule/Tablet Production