Precision, Compliance, and Efficiency for Your Production Line

Magnetic Products Inc. (MPI) Checkweighers are precisely engineered systems designed to deliver accurate weight measurements for products on production lines. These systems detect overfills, underfills, and weights that fall outside specified limits, thereby guaranteeing product quality and compliance with regulatory standards. MPI Checkweighers are ideally suited for industries requiring fast, accurate, and dependable weight verification, such as food processing, pharmaceuticals, manufacturing, and packaging.

Designed for high-speed operation, MPI Checkweighers effectively measure product weight and ensure adherence to packaging specifications as items move along the production line. By classifying products into specific weight categories, these systems streamline the sorting or rejection of items based on predetermined criteria. This not only enhances quality control and compliance but also boosts customer satisfaction while minimizing product waste, leading to substantial savings.

Checkweighers provide an exceptional solution for monitoring product weight, throughput, and efficiency in packaging and filling operations. Designed for effortless integration into your production line, these conveyor-fed systems ensure optimal performance.

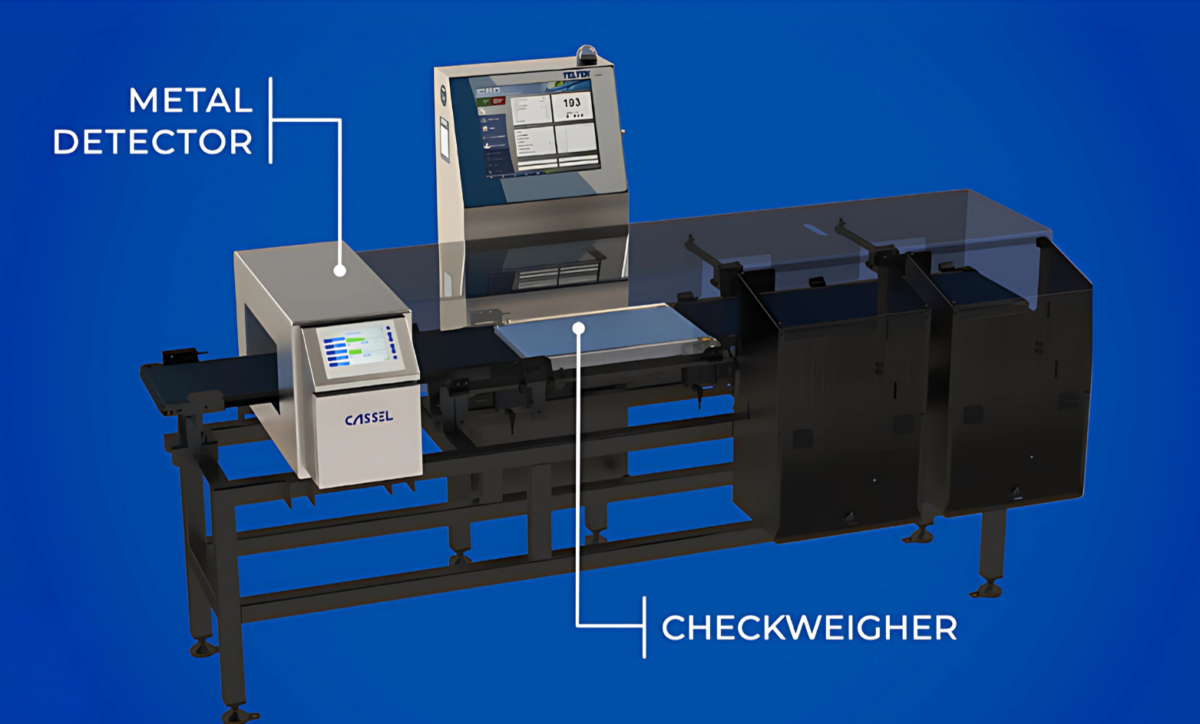

To further enhance quality control, checkweighers can be provided as standalone units or as part of a comprehensive solution, incorporating extensive inspection capabilities within a single integrated system.

Enhance your production process with MPI Checkweighers—offering precision, compliance, and efficiency at every stage.

Benefits of the Checkweigher From Magnetic Products, Inc

-

Inline Weight Verification & High-Speed Accuracy

Precisely measures and verifies product weight in real-time, ensuring accuracy even in high-speed production lines.

-

Automated Product Rejection

Detects and removes non-conforming products based on customizable weight thresholds to maintain quality control.

-

Seamless System Integration

Easily integrates with existing conveyor systems and production lines to enhance overall efficiency.

-

Advanced Precision & Durability

Utilizes high-precision load cell technology and stainless steel construction for accuracy, hygiene, and longevity.

-

User-Friendly & Real-Time Monitoring

Intuitive touchscreen interface with real-time data display for instant feedback and operational adjustments.

-

Comprehensive Data Logging & Compliance

Tracks production counts, batch data, weight statistics, and rejected items to support regulatory compliance and reporting.

-

Customizable Settings for Versatile Applications

Adjustable weight thresholds make it suitable for industries such as food, pharmaceuticals, cosmetics, beverages, and manufacturing.

-

Compact & Scalable Design

Fits seamlessly into production lines without requiring major modifications and is available as a standalone unit or paired with a METAL SHARK metal detector for added quality control.

Checkweigher Product Details

MPI Checkweighers incorporate sophisticated load cell technology to accurately assess the weight of products as they traverse a weighing platform. Real-time data analysis ensures that the product meets the defined weight specifications. If a product is found to be overfilled, underfilled, or otherwise non-compliant, the system activates an automatic rejection mechanism to remove it from the production line. Operators can intuitively oversee weight data and system performance, enabling consistent product quality and regulatory compliance.

Checkweighers efficiently and precisely ascertain various products' weight and corresponding packaging requirements in motion along the production line. Items are categorized by predefined weight zones, allowing for sorting or rejection based on these classifications. These systems promote quality control and customer satisfaction by ensuring products adhere to target weights while achieving cost savings by reducing excess product giveaways.

Checkweighers ensure compliance with governmental regulations and facilitate product tracking. Captured data includes production counts, batch tracking, total weights, acceptable weights, and rejected weights. Various industries, including food, pharmaceuticals, cosmetics, beverages, transportation, chemicals, automotive, and metal manufacturing, integrate checkweigher systems into their production processes.

Smaller Scale

Drag chain style checkweighers are ideal for smaller scale applications such as cans, jars, small cartons (like coffee), canned foods, pet foods, nutraceuticals, paints, adhesives, produce, candies, boxes, tubs, cartons, and other rigid containers. These systems utilize two strands of flat-link chain to transport rigid packages across a fixed scale section. Standard conveyor lengths measure 36 inches; weigh table lengths vary from 3 to 14 inches; and conveyor widths range from 1 to 10 inches. Conveyor speeds can reach up to 400 feet per minute, with performance rates of up to 350 packages per minute and an accuracy of ±0.5 grams for weights up to 10 pounds.

Small belt conveyors are widely used for rigid, semi-rigid, and flexible packages containing produce, meat, poultry, ice cream, FFS bagged sauces, flow-wrapped baked goods, coffee, tea, small cartons, and spices. Available belt conveyor lengths include 12, 14, 18, 20, 24, and 28 inches, with belt widths from 4 to 18 inches. Conveyor speeds reach up to 300 feet per minute, accommodating performance rates of up to 220 packages per minute and an accuracy of ±0.5 grams at 2 Sigma for capacities up to 20 pounds.

Heavy Duty

Heavy-duty checkweigher systems are commonly used for concrete, cement, salt, sand, and earth products. Conveyor speeds are variable, reaching up to 250 feet per minute, with performance rates of up to 50 packages per minute and an accuracy of ±0.05 pounds at 2 Sigma for capacities up to 110 pounds, with repeatability as precise as ±0.03 pounds at 2 Sigma.

Checkweigher Specification Table

US Customary Units

| MODEL # | CW-MD-HIQ-230 | CW-MD-HIQ-230 |

|---|---|---|

| RANGE | 20-2000G | 20-5000G |

| SCALE INTERVAL | 0.1g | 0.2g |

| ACCURACY (3 SD) | +/- 0.2G | +/- 0.5G |

| MAXIMUM SPEED | 155 PCS/MIN. | 140 PCS/MIN. |

| BELT SPEED | 230 FT./MIN. | 230 FT./MIN. |

| PRODUCT SIZE WIDTH | 9 IN. | 14 IN. |

| PRODUCT SIZE LENGTH | 14 IN. | 16 IN. |

| PRODUCT SIZE HEIGHT | 3 IN. / 4 IN. / 5.5 IN. / 7 IN. | 3 IN. / 4 IN. / 5.5 IN. / 7 IN. |

| WEIGH PLATFORM WIDTH | 9 IN. | 12 IN. |

| WEIGH PLATFORM LENGTH | 18 IN. | 20 IN. |

| WEIGH PLATFORM HEIGHT | 3 IN. / 5 IN. / 6 IN. / 7 IN. | 3 IN. / 5 IN. / 6 IN. / 7 IN. |

| SENSITIVITY MO. (FE) | 0.5 IN. | 0.5 IN. |

| SENSITIVITY MO. (SUS) | 0.5 IN. | 0.5 IN. |

| PRODUCT STORAGE QTY. | UP TO 100 | UP TO 100 |

| SEGMENTS # OF SORTING | UP TO 3 | UP TO 3 |

| REJECT | VARIETY OF STYLES | VARIETY OF STYLES |

| POWER SUPPLY | AC220V (OPTIONAL) | AC220V (OPTIONAL) |

| DEGREE OF PROTECTION | IP54 / IP66 | IP54 / IP66 |

| MAIN MATERIAL | STAINLESS STEEL 304 | STAINLESS STEEL 304 |

Checkweigher Installations & Variations

Checkweigher Verifying that Packaged Goods Meet Labeled Weight

Logistics Checkweigher Detecting Packaging Errors Before Final Shipment

Checkweigher Monitoring Overfilled of Underfilled Pails, Drums, and Bags