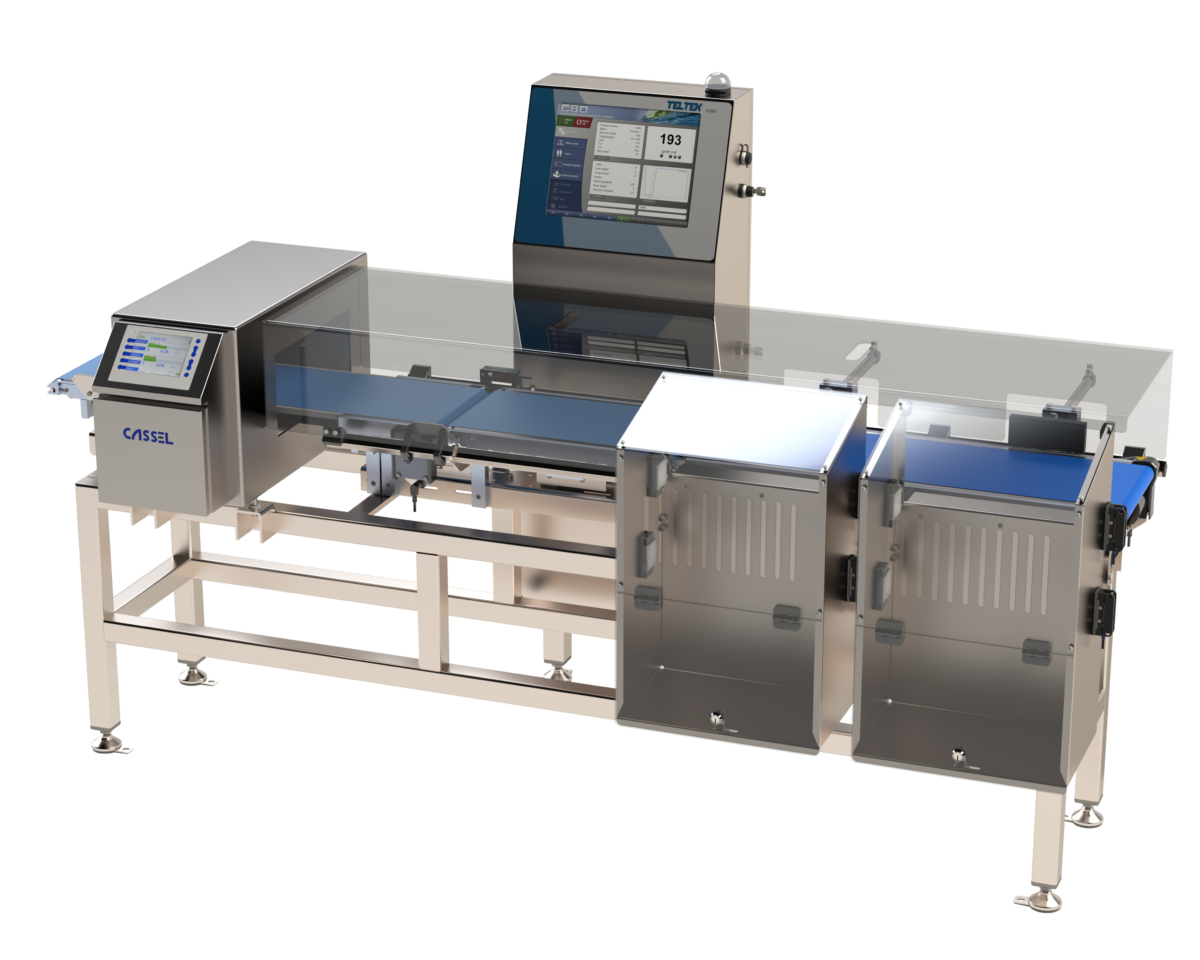

Dual-Function Inline System for Contaminant Detection and Weight Verification

MPI’s Combination Metal Detector and Checkweigher is an integrated, space-saving solution designed to simultaneously detect ferrous and non-ferrous metal contaminants and verify product weight compliance in a single pass. Engineered for high-throughput production lines in food, pharmaceutical, pet food, and consumer goods industries, this system ensures both product safety and regulatory weight accuracy, helping manufacturers prevent recalls, avoid fines, and maintain customer trust.

Combining advanced multi-frequency metal detection with precision load cell-based checkweighing, MPI’s combo unit is built for rugged reliability, fast changeovers, and easy operation. It automatically rejects non-conforming products from the line via configurable reject mechanisms—minimizing waste, reducing labor, and keeping lines moving efficiently.

Offered in various configurations to match product size, line speed, and environmental requirements, MPI’s Combo Metal Detector/Checkweigher delivers reliable performance with a user-friendly interface and robust hygienic design.

Benefits of the Combination Metal Detector and Checkweigher From Magnetic Products, Inc

-

Dual Functionality in One Compact System

It combines high-sensitivity metal detection and precision weight checking in one machine, reducing its footprint and simplifying installation and operation on crowded production lines.

-

Multi-Frequency Metal Detection

Detects ferrous, non-ferrous, and stainless-steel contaminants using advanced multi-frequency technology, ensuring consistent performance across various product types, densities, and packaging materials.

-

High-Accuracy Check Weighing

Utilizes a precision strain-gauge or electromagnetic load cell system to weigh products on-the-fly, accurately identifying underweight or overweight items in compliance with legal-for-trade and QA standards.

-

Customizable Reject Mechanisms

Automatically removes non-conforming products with customizable reject devices, including air blast, pusher, flipper, or drop belt, configured to match product weight, speed, and packaging type.

-

User-Friendly Touchscreen Interface

Intuitive HMI with multi-language support, recipe storage, and guided calibration makes setup and operation simple, even for line operators. Optional network connectivity allows data tracking and remote monitoring.

-

Stainless Steel Hygienic Construction

Built with 304 or 316 stainless-steel to withstand harsh washdown environments in food, pharma, or chemical facilities. Sloped surfaces, minimal crevices, and IP-rated enclosures support sanitary compliance.

-

High-Speed Operation

Designed for continuous, high-volume production, with line speeds up to 250 feet per minute (depending on configuration), ensuring accurate performance without bottlenecking throughput.

-

Supports Regulatory Compliance

Ensures adherence to FDA, USDA, FSMA, and global weight and traceability regulations. Optional features include audit trail logging, rejection statistics, and password-protected user levels.

Combination Metal Detector and Checkweigher Product Details

MPI’s Combination Metal Detector and Checkweigher integrates two key inspection functions into a seamless in-line process, typically located at the end of a packaging line or before final boxing.

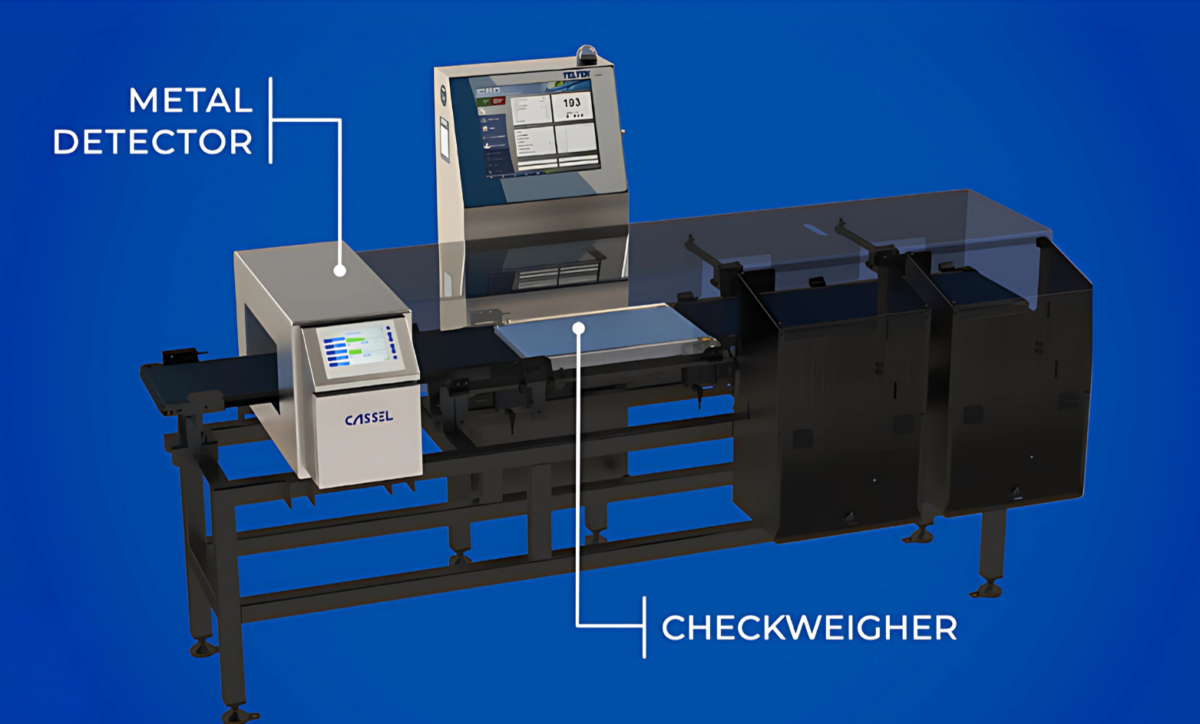

Product Infeed

Products are conveyed onto the system via a conveyor belt or infeed transfer. A timing sensor ensures spacing between items for accurate inspection.

Metal Detection Phase

As the product passes through the metal detector head, it is scanned using multi-frequency electromagnetic fields that can detect minute amounts of ferrous, non-ferrous, and stainless-steel contaminants, even though the packaging.

A signal is sent to the reject mechanism to remove the contaminated product from the line if metal is detected.

Checkweighing Phase

The product then passes onto the weighing conveyor, which captures its weight in motion using a highly sensitive strain-gauge or electromagnetic load cell.

- The system compares the actual weight to preset upper and lower thresholds.

- The reject system is triggered if the product is out of spec (too light or too heavy).

Reject and Collection

Products that fail either inspection (metal contamination or incorrect weight) are diverted from the production line using the designated reject mechanism, ensuring only safe and compliant products proceed downstream.

Data Logging and QA Reporting

All inspection results—including time stamps, reject reasons, batch IDs, and user activity—can be logged for traceability and compliance audits. Data can be stored locally or sent to a centralized quality control system.

Combination Metal Detector and Checkweigher Specification Table

US Customary Units

| MODEL # | CW-MD-HIQ-230 | CW-MD-HIQ-230 |

|---|---|---|

| RANGE | 20-2000G | 20-5000G |

| SCALE INTERVAL | 0.1g | 0.2g |

| ACCURACY (3 SD) | +/- 0.2G | +/- 0.5G |

| MAXIMUM SPEED | 155 PCS/MIN. | 140 PCS/MIN. |

| BELT SPEED | 230 FT./MIN. | 230 FT./MIN. |

| PRODUCT SIZE WIDTH | 9 IN. | 14 IN. |

| PRODUCT SIZE LENGTH | 14 IN. | 16 IN. |

| PRODUCT SIZE HEIGHT | 3 IN. / 4 IN. / 5.5 IN. / 7 IN. | 3 IN. / 4 IN. / 5.5 IN. / 7 IN. |

| WEIGH PLATFORM WIDTH | 9 IN. | 12 IN. |

| WEIGH PLATFORM LENGTH | 18 IN. | 20 IN. |

| WEIGH PLATFORM HEIGHT | 3 IN. / 5 IN. / 6 IN. / 7 IN. | 3 IN. / 5 IN. / 6 IN. / 7 IN. |

| SENSITIVITY MO. (FE) | 0.5 IN. | 0.5 IN. |

| SENSITIVITY MO. (SUS) | 0.5 IN. | 0.5 IN. |

| PRODUCT STORAGE QTY. | UP TO 100 | UP TO 100 |

| SEGMENTS # OF SORTING | UP TO 3 | UP TO 3 |

| REJECT | VARIETY OF STYLES | VARIETY OF STYLES |

| POWER SUPPLY | AC220V (OPTIONAL) | AC220V (OPTIONAL) |

| DEGREE OF PROTECTION | IP54 / IP66 | IP54 / IP66 |

| MAIN MATERIAL | STAINLESS STEEL 304 | STAINLESS STEEL 304 |

Compatibility Check - Combination Metal Detector and Checkweigher Installations

Easyweigh Combination Metal Detector & Checkweigh System for Pharmaceutical Packaging

Combination Metal Detector & Checkweigh System for Food Processing & Packaging

Combination Metal Detector & Checkweigh System for Consumer-Packaged Goods (CPG)