Works in Rugged, Industrial Environments

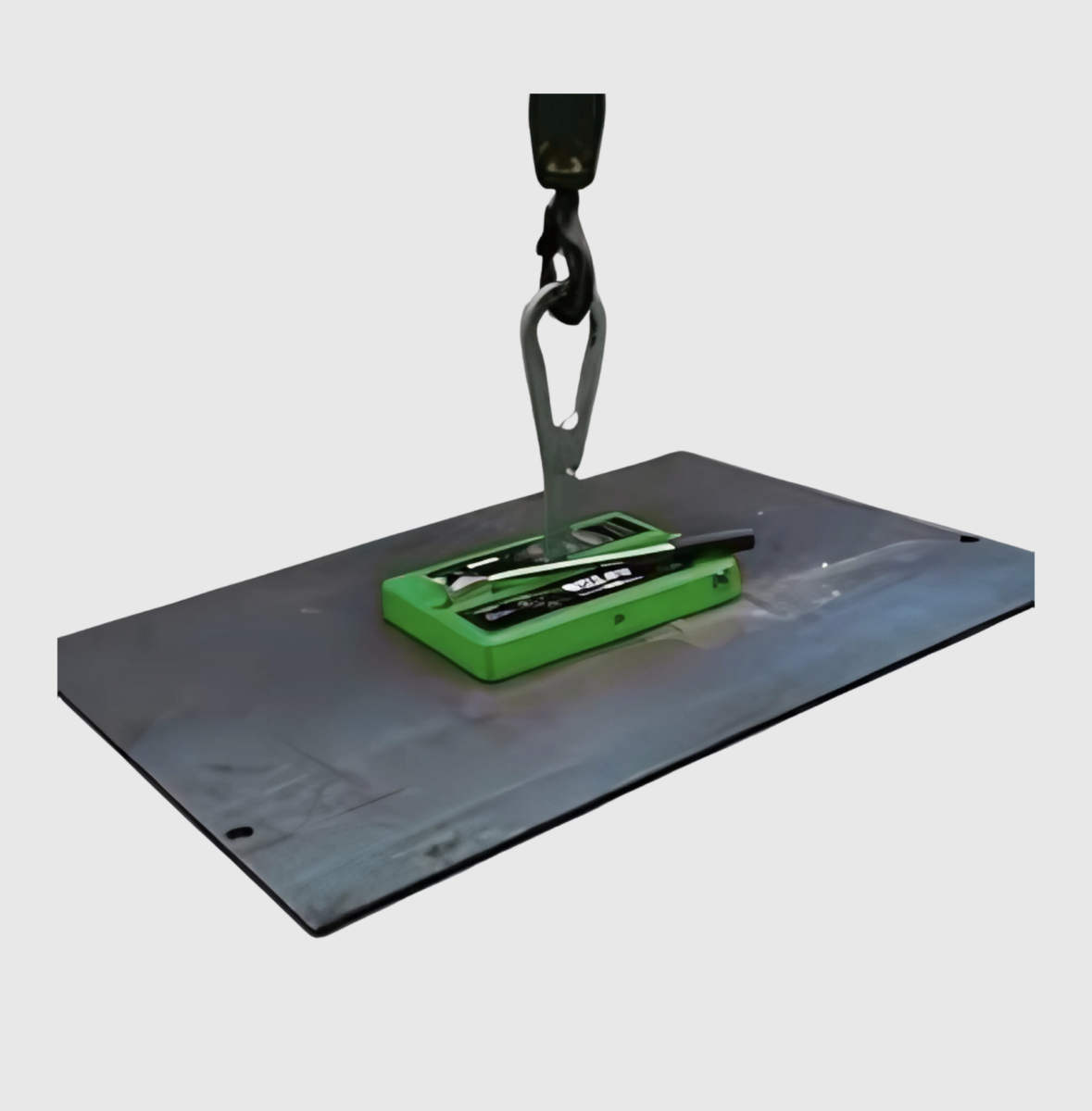

MPI’s Permanent Crane Magnet is a robust, power-free lifting solution engineered for safe, efficient handling of heavy steel plate, structural shapes, bars, and large ferrous loads in demanding environments like steel service centers, shipyards, and fabrication yards. Using powerful rare-earth or ceramic magnets, it delivers consistent, high-strength clamping force without the need for an electrical connection—making it fail-safe during power outages. Operators easily engage and disengage the magnetic force using a secure, mechanical lever, ensuring quick setup and clean release. Designed to withstand rugged industrial use, the Permanent Crane Magnet reduces rigging time, minimizes the need for slings or hooks, and boosts productivity while enhancing operator safety for large-scale lifting operations.

Benefits of the Permanent Crane Magnet From Magnetic Products, Inc

-

No External Power Needed

Fully self-contained magnet ensures reliable lifting even in remote or outdoor sites.

-

High Holding Force for Heavy Loads

Engineered for large plates, beams, or bulk ferrous materials.

-

Safe Mechanical Activation

Manual on/off lever with safety lock prevents accidental switching during lifts.

-

Fail-Safe Design

Holds loads securely with no drop risk if electrical power is unavailable.

-

Zero Residual Magnetism

Clean release ensures easy unloading and prevents sticking.

-

Heavy-Duty Construction

Rugged build withstands harsh conditions and frequent use.

-

Reduces Rigging Time & Costs

Eliminates need for chains, hooks, or slings—speeds up loading/unloading.

-

Boosts Operator Safety

Minimizes manual handling, lowering the risk of injuries in lifting operations.

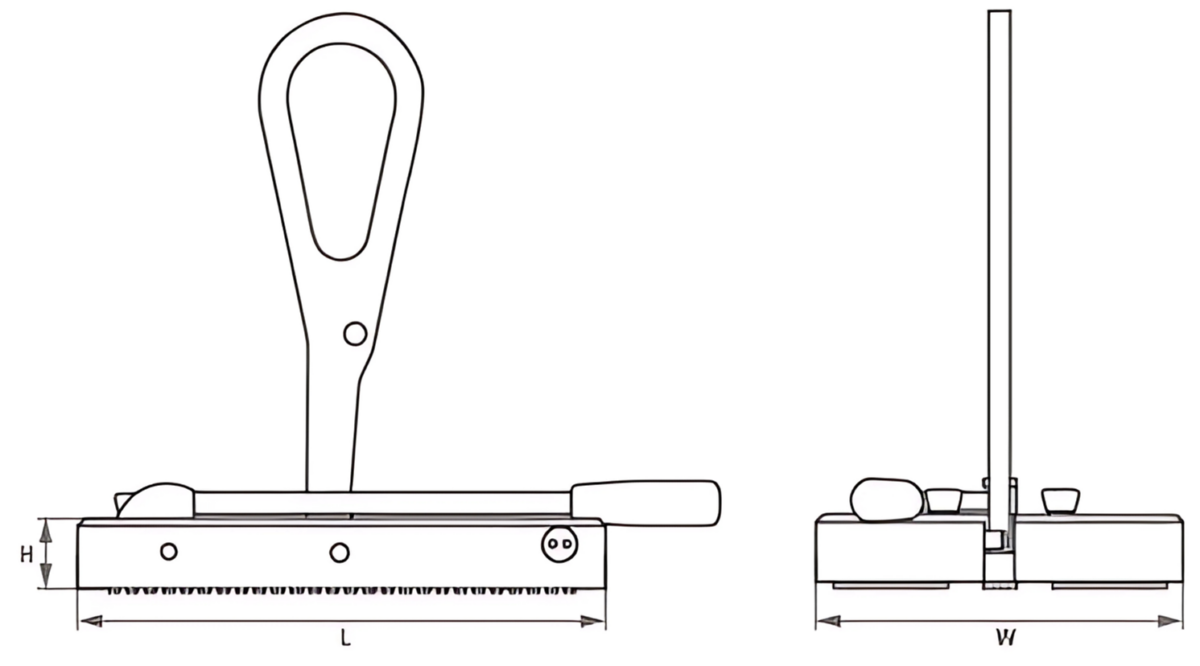

Permanent Crane Magnet Product Details

The MPI Permanent Crane Magnet allows easy lifting and handling of sheets and steel plates from horizontal to vertical positions and vice versa. The large lifting eye is lockable and prevents undesirable tilting from horizontal to vertical positions. The lockable release lever is comfortable and safe for the operator.

Position

Place the Permanent Crane Magnet firmly onto the flat, clean surface of the ferrous load.

Engage

Pull or rotate the mechanical lever to the ON position. This rotates the internal magnet core, directing its magnetic field outward and securely clamping onto the material.

Lift

Connect the lifting eye to the crane hook or hoist and safely lift the load.

Move & Position

Transport and position the load as needed with stable magnetic holding.

Release

Once positioned, lower the load, then move the lever back to the OFF position to rotate the magnet core internally, collapsing the field.

Remove

The magnet releases cleanly with no residual magnetism—ready for the next lift.

Permanent Crane Magnet Specification Table

US Customary Units

| MODEL # | WIDTH (IN.) | LENGTH (IN.) | HEIGHT (IN.) | HORIZONTAL LIMIT (LBS.) | VERTICAL LIMIT (LBS.) | WEIGHT (LBS.) | TESTED BREAKAWAY FORCE (LBS.) |

|---|---|---|---|---|---|---|---|

| PCM-GP250 | 7.8 | 11.3 | 1.6 | 551 | 176 | 21.5 | 2,425 |

Compatibility Check - Permanent Crane Magnet Installations

Permanent Crane Magnet Used for Its Clean-Release Which Leaves No Residual Magnetism

MPI Permanent Crane Magnet Preferred for Its Adjustable Pole Shoes

MPI Permanent Crane Magnet Booss Operator Safety and Ergonomics