Automated Parts Removal from Stamping Presses

The MPI Parts-Out Conveyor is a rugged, low-profile conveyor system engineered to quickly and cleanly evacuate finished parts or scrap from the die area of stamping presses, forming machines, and other industrial fabrication equipment. Built for durability and precision, this belt-driven solution is ideal for light to moderate material handling, including finished parts and metal scrap. With its compact footprint and modular design, the Parts-Out Conveyor integrates seamlessly into existing press lines, robotic systems, or automated cells, boosting productivity, minimizing downtime, and enhancing operator safety. The Parts-Out Conveyor delivers repeatable, reliable performance in demanding industrial settings, whether used to remove delicately formed parts or heavy-duty scrap.

Benefits of the Part-Out Conveyors From Magnetic Products, Inc

-

Low-Profile Construction

Enables installation under low clearance presses or compact work cells without modification.

-

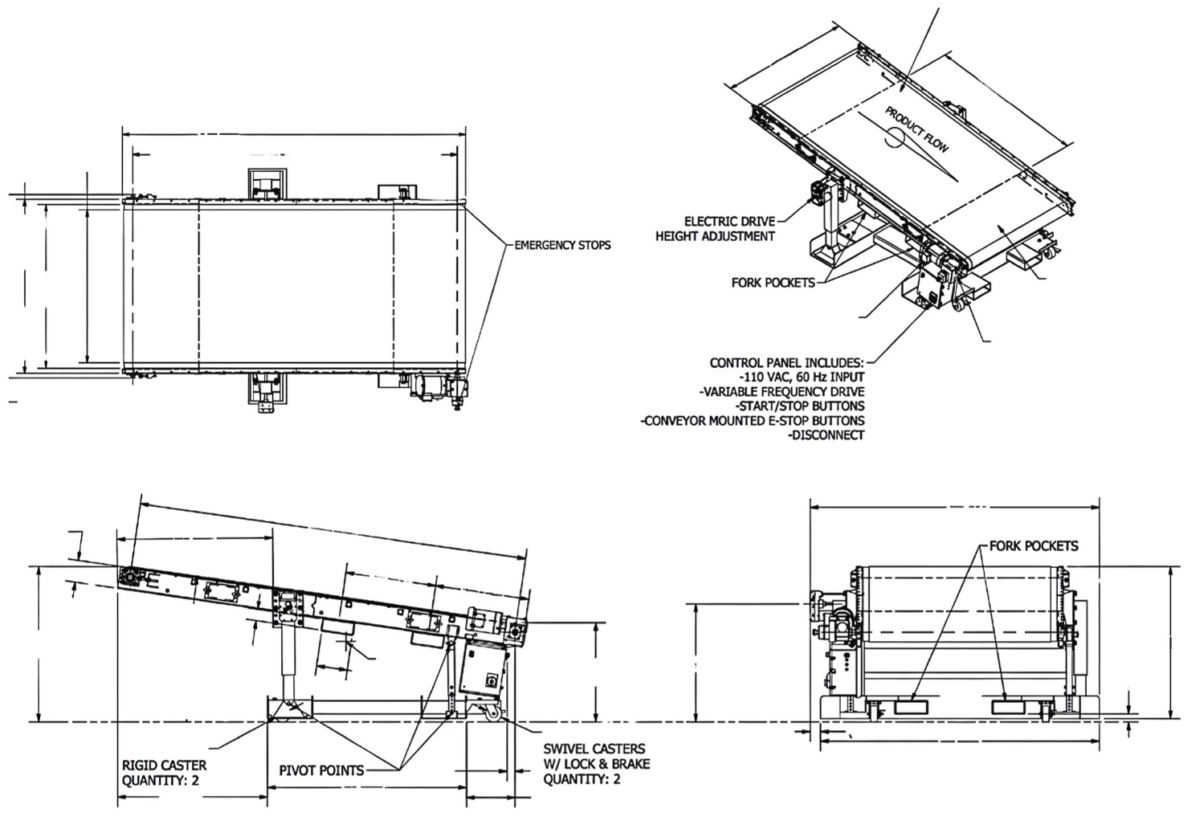

Adjustable Discharge Height and Angle

Offers flexible placement into totes, bins, or downstream automation equipment.

-

Heavy-Duty Frame and Belt Design

Built to withstand harsh environments and continuous-duty cycles in metal stamping operations.

-

Integrated Part/Scrap Separation

Optional chutes or diverters allow easy sorting of parts from runners, slugs, or scrap.

-

Quiet, Smooth Operation

Precision belt tracking and high-efficiency motor reduce noise and vibration.

-

Tool-Free Belt Removal or Tensioning

Simplifies maintenance and cleaning, minimizing line downtime.

-

Integrated Controls or Standalone Operation

Easily ties into existing press or automation control systems.

-

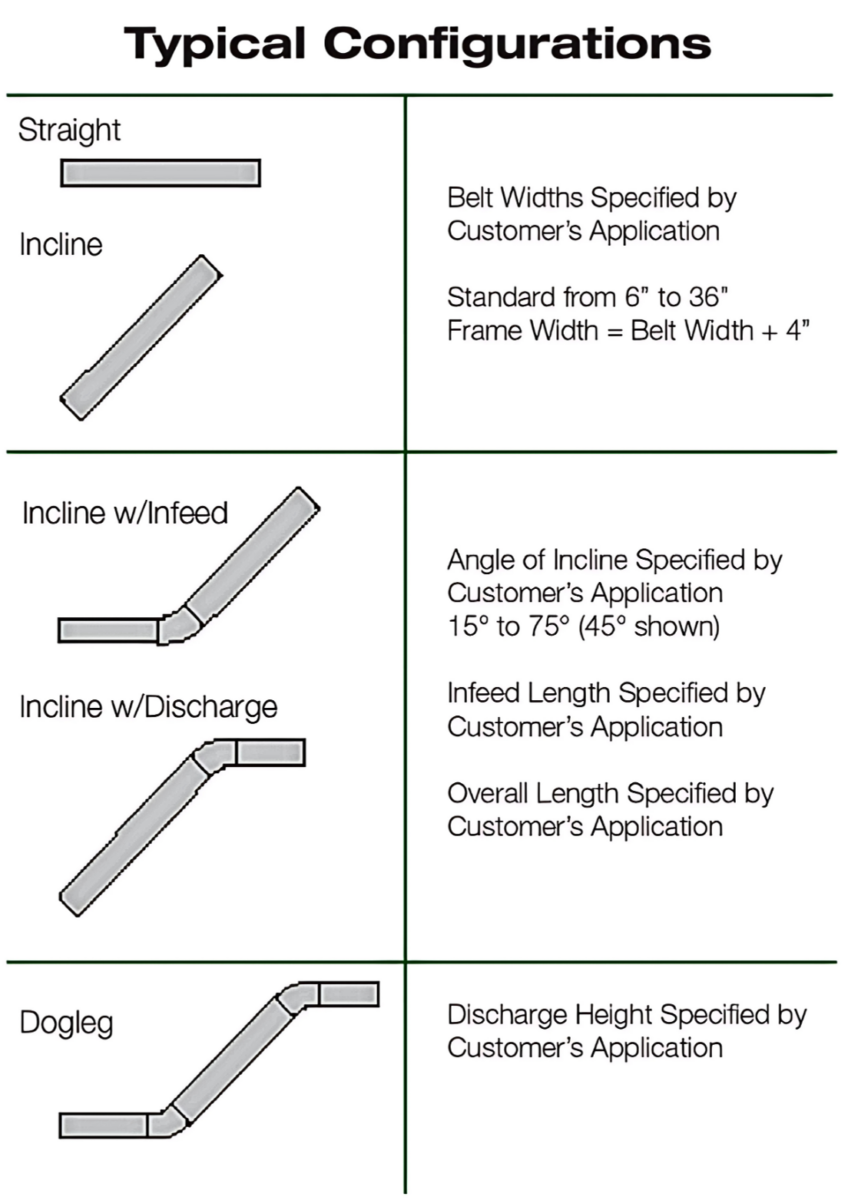

Modular Design

Available in custom lengths, widths, and configurations to match application-specific needs.

Part-Out Conveyors Product Details

Positioned Near the Die or Part Drop Area

The conveyor is installed directly beneath the press or die to capture parts or scrap as they fall.

Material Falls onto the Conveyor Belt

As the stamping or forming process ejects finished components or scrap, they land safely on the belt.

Belt Moves Items Away from the Press

The motorized belt carries the material laterally or upward to a designated discharge point.

Optional Part/Scrap Diverters

Configurations may include diverters or sorters to separate usable parts from waste.

Discharge to Bin, Tote, or Secondary Process

Finished parts or scrap exit the conveyor into containers or are transferred to the next process step.

Continuous or Intermittent Operation

Based on control integration, the conveyor can be synced with press cycles or run continuously.

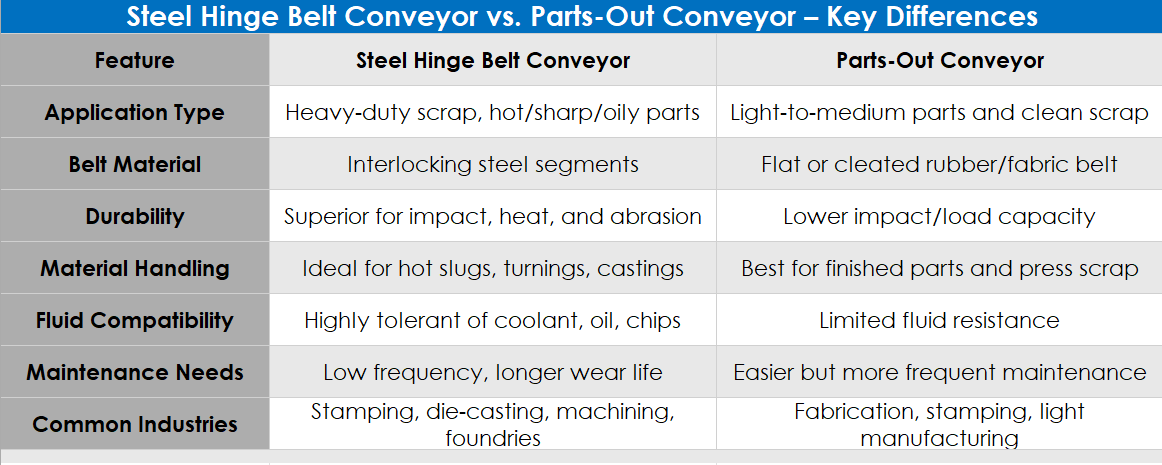

Part-Out Conveyors Specification Table

US Customary Units

| MODEL FEATURE | STANDARD | HEAVY DUTY | EXTRA HEAVY CAPACITY |

|---|---|---|---|

| Pitch (in.) | 2.5 in. | 4 in. | 6 in. |

| Frame Depth (in.) | 8.5 in. | 15.25 in. | 23.25 in. |

| Frame Gauge ) | 12 | 10 | Channel |

| Drive Size | 6-Tooth | 6-Tooth | 6-Tooth |

Compatibility Check - Part-Out Conveyors Installations

Part Out Conveyor Used for Workstation Delivery

Part Out Conveyor Used in Aerospace Parts Manufacturing Application

Cold Heading Part Conveyor with Hopper