Simple Scrap Management

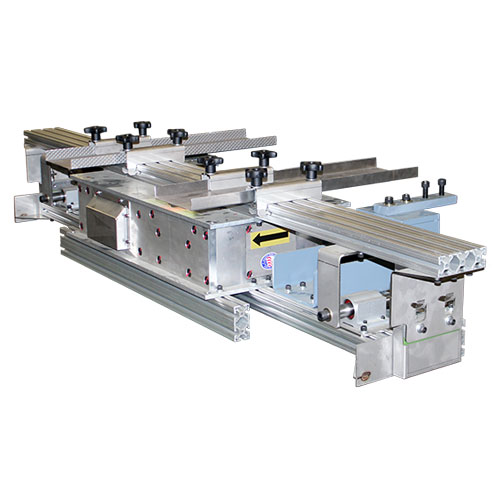

The MPI M-200 Electric Scrap Shaker is a high-capacity, ultra-heavy-duty scrap removal solution built for the most demanding industrial environments. Engineered for continuous operation under extreme loads, the M-200 delivers robust and consistent linear motion to drive extensive scrap tray systems servicing multiple presses or work cells. This powerhouse shaker is ideal for large-scale stamping, metal forming, or robotic manufacturing operations generating high scrap volumes. With an oversized frame, precision-tuned drive system, and durable construction, the M-200 enhances scrap flow efficiency, eliminates manual handling, and ensures a clean, safe production floor—even in the harshest conditions.

Benefits of the M-200 Electric Scrap Shaker From Magnetic Products, Inc

-

Extreme-Duty Design

Built to handle the highest scrap loads, largest tray systems, and most aggressive production environments.

-

Centralized Scrap Handling

Drives long, interconnected tray systems beneath multiple workstations or press lines from a single unit.

-

Powerful, Electric Linear Motion

No compressed air is required, which provides efficient, consistent movement and simplifies infrastructure.

-

Designed for 24/7 Operation

Robust bearings, reinforced frame, and sealed components withstand round-the-clock heavy use.

-

Optimized Plant Efficiency

Automates scrap removal to reduce labor needs, prevent press shutdowns, and maintain clean operations.

-

Low-Maintenance Reliability

Simple mechanical design with minimal wear parts ensures long service life with low upkeep.

-

Quiet Performance in Harsh Settings

Smooth electric drive reduces shop floor noise and performs reliably in abrasive, oily, or high-debris environments.

-

Flexible Control Options

Integrates with press automation systems or runs independently with manual or timed control.

M-200 Electric Scrap Shaker Product Details

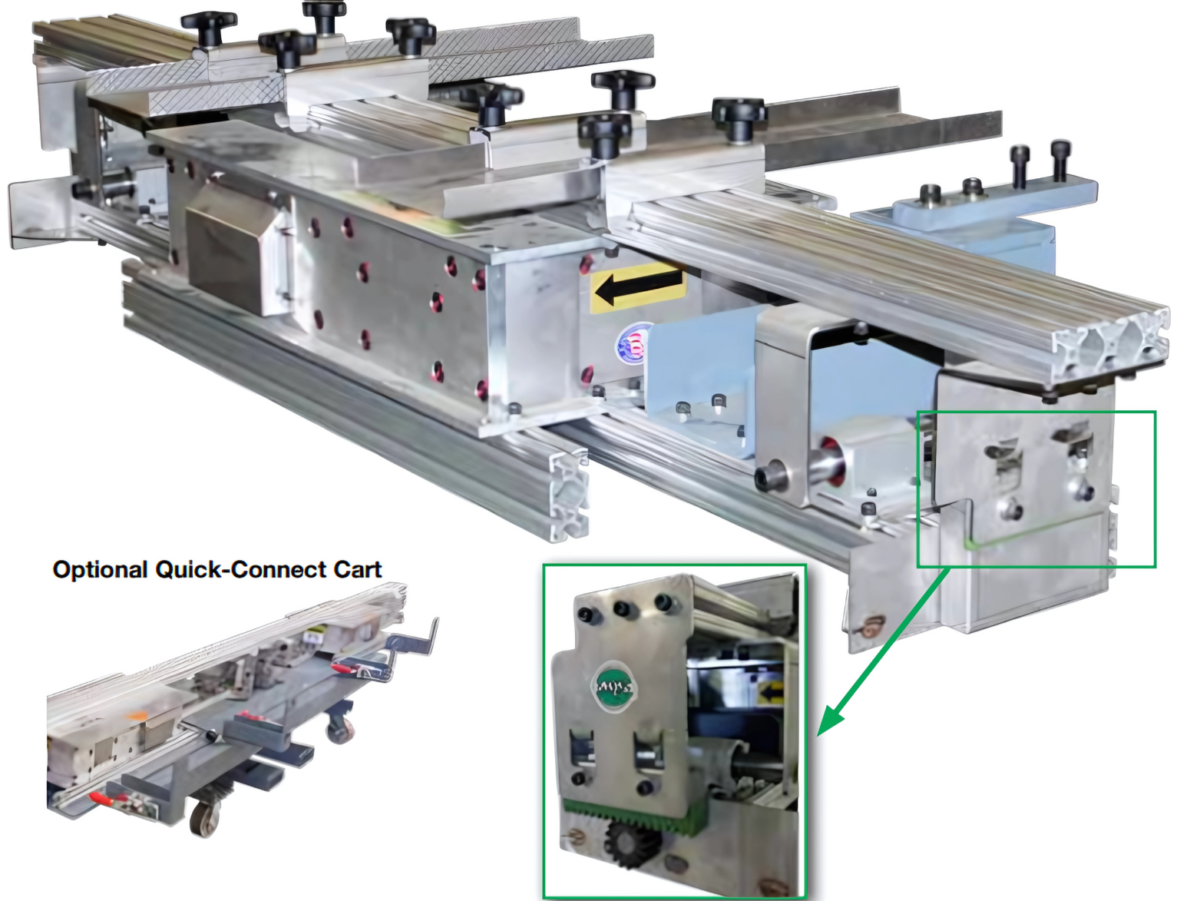

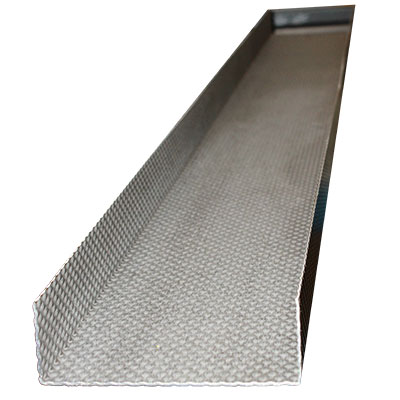

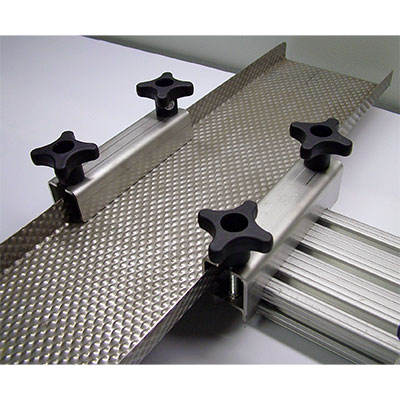

The M Series press-mounted scrap conveyor utilizes a patented electric shaker motor to move scrap metal using metal pans efficiently. This motor facilitates a slow, low-frequency movement with a quick return, propelling stamping scrap forward. The motor attaches securely to the bolster using T-slot mounts, which can fit into standard T-slots. A crossbar made from extruded aluminum allows operators to attach metal pans, which are adjustable using Quick Release Pan Mount Bracket Accessories, to position between the die uprights for optimal scrap collection. The conveyor supports multiple pans of various sizes, with recommendations for balanced loads on specific models. Shaker pans manufactured by MPI or customers can be customized for any required shape or size. The setup should align the top of the crossbar with the bolster height. The system operates nearly silently with a high-efficiency motor, potentially reducing operating costs by up to 71% compared to pneumatic designs, and reliably conveys scrap at 20 feet per minute. The M-200 model can integrate with various conveyor types for a comprehensive scrap handling solution and features an installation process, power activation options, and continuous operation capabilities for streamlined scrap clearance.

Installation

The M-200 unit is floor- or pit-mounted under a large press row, robotic cell, or integrated tray system.

Power Activation

The electric shaker powers on to initiate vibration via the control panel or a press-synchronized relay.

Vibratory Drive Engaged

A heavy-duty linear motion drive generates high-force oscillations, vibrating the entire scrap tray system.

Scrap Movement Begins

Scrap materials begin traveling steadily down the tray(s) length toward centralized discharge points.

Discharge

Scrap exits into bins, roll-away hoppers, or integrated conveyors at the tray’s end.

Continuous Operation

The M-200 runs continuously or in timed intervals to match production, ensuring nonstop scrap clearance without manual effort.

M-200 Electric Scrap Shaker Specification Table

Power Input: 110VAC, single phase / T-Slot: 0.50″ Thick x 1.375″ Wide and 3/4″ Thick x 1.75″ Wide / Design Capacity (Pan & Scrap) - 200 LBS. / Release Pan Mount Brackets NOT Included

| MODEL FEATURE | M-200 Motor Only | M-200-MP4 | M-200-MP5 | M-200-MP6-RP | M-200-MP7-RP | M-200-MP8-RP | M-200-MP9-RP | M-200-MP10-RP | M-200-MP11-RP | M-200-MP12-RP | M-200-MP13-RP | M-200-MP14-RP | M-200-MP15-RP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CROSSBAR WIDTH (IN.) | Not Included | 48 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 | 180 |

| SYSTEM WEIGHT (LBS.) | 165 | 175 | 188 | 236 | 245 | 254 | 264 | 313 | 322 | 331 | 340 | 350 | 360 |

| NUMBER OF BOLSTER MOUNTS | Not Included | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 |

M-200 Electric Scrap Shaker Installations & Variations

M-200 Shaker for Automotive Parts Production

M-200 Scrap Shaker Used for Robotic Sheet Metal Fabrication Cells

M-200 Scrap Shaker Large-Scale Metalforming and Steel Processing Operation