Tramp Metal Removal Without Shutdown

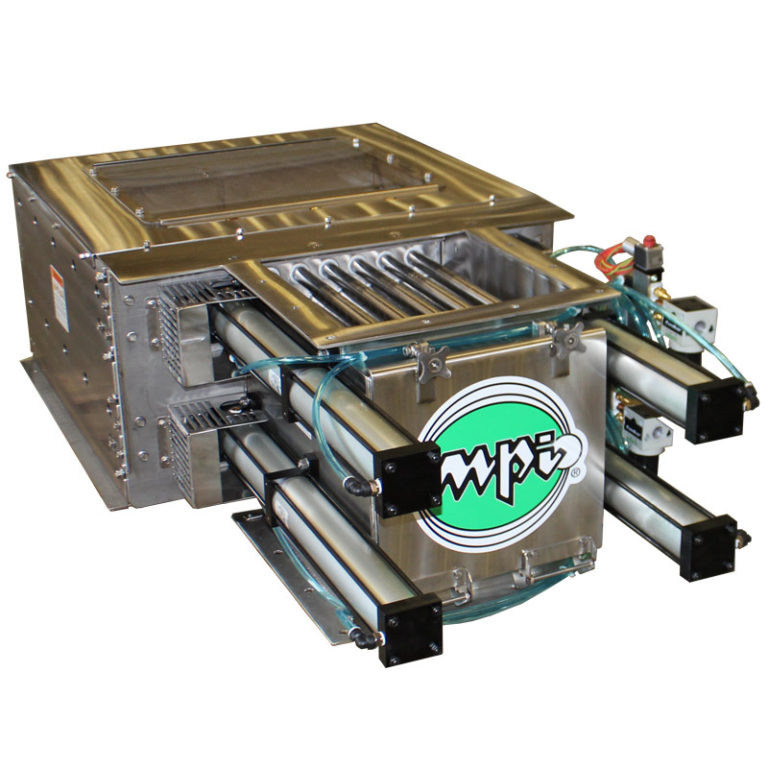

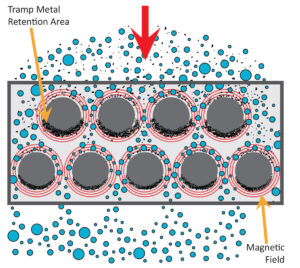

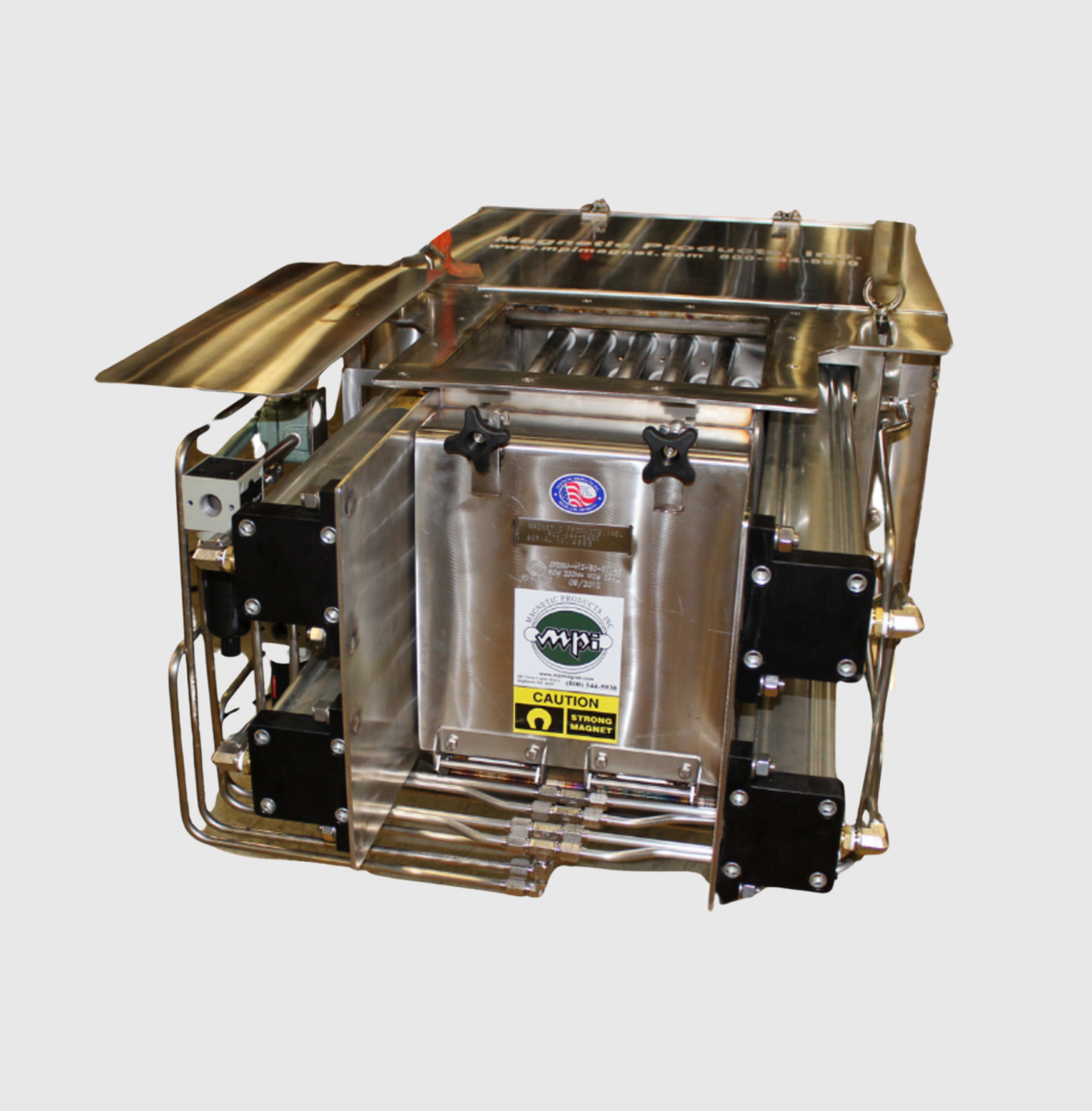

1” Automated Self-Clean Drawer Magnets utilize a specialized magnetic circuit designed for the efficient capture of small contaminants, such as metal shavings and wear, from dry powder or granular products in gravity-fed chutes. The MPI Automated Self-Clean 200 Series Drawer Magnets enhance equipment protection during processing operations like milling and mixing and uphold high product quality through their automatic cleaning feature. These magnets consist of two tiers of high-intensity rare earth magnetic tubes, ensuring maximum contact with the product stream to eliminate ferrous tramp metal effectively. The staggered arrangement of the 1-inch diameter tubes prevents product bridging and maximizes filtration efficiency. As the product flows through the housing, tramp metal is attracted to the magnetic tubes, and a pneumatically operated cleaning system removes the contaminants to a designated disposal area, maintaining a clean product stream.

Benefits of the One Inch Tube Continuous-Clean Drawer Magnet From Magnetic Products, Inc

-

Powerful Magnetic Filtration

Two-tier high-intensity rare earth magnets maximize metal separation through direct product contact.

-

Continuous Product Flow

No need to stop product flow during the magnet cleaning cycle, ensuring uninterrupted processing.

-

Automated Cleaning Cycle

Reduces manual labor and downtime with an efficient, solenoid-actuated cleaning process.

-

Easy Maintenance and Access

Rear access panel and bolt-on stainless steel safety cage simplify inspection and testing.

-

Enhanced Product Protection

Two magnet rows remain active while cleaning, maintaining product safety at all times.

-

Durable and Hygenic Design

Stainless steel construction with a Sani-TIGHT Seal™ gasket ensures long-lasting, sanitary operation.

-

Leak and Misalignment Prevention

Extended drawer front minimizes product leakage, while internal supports prevent misalignment.

-

Static Discharge Prevention

Integrated grounding strap prevents static buildup, enhancing operational safety.

One Inch Tube Continuous-Clean Drawer Magnet Product Details

The continuous flow drawer magnets from MPI incorporate two tiers of high-intensity rare earth magnetic tubes, providing superior magnetic filtration through direct product contact on the tubes, which captures ferrous tramp metal from the product stream.

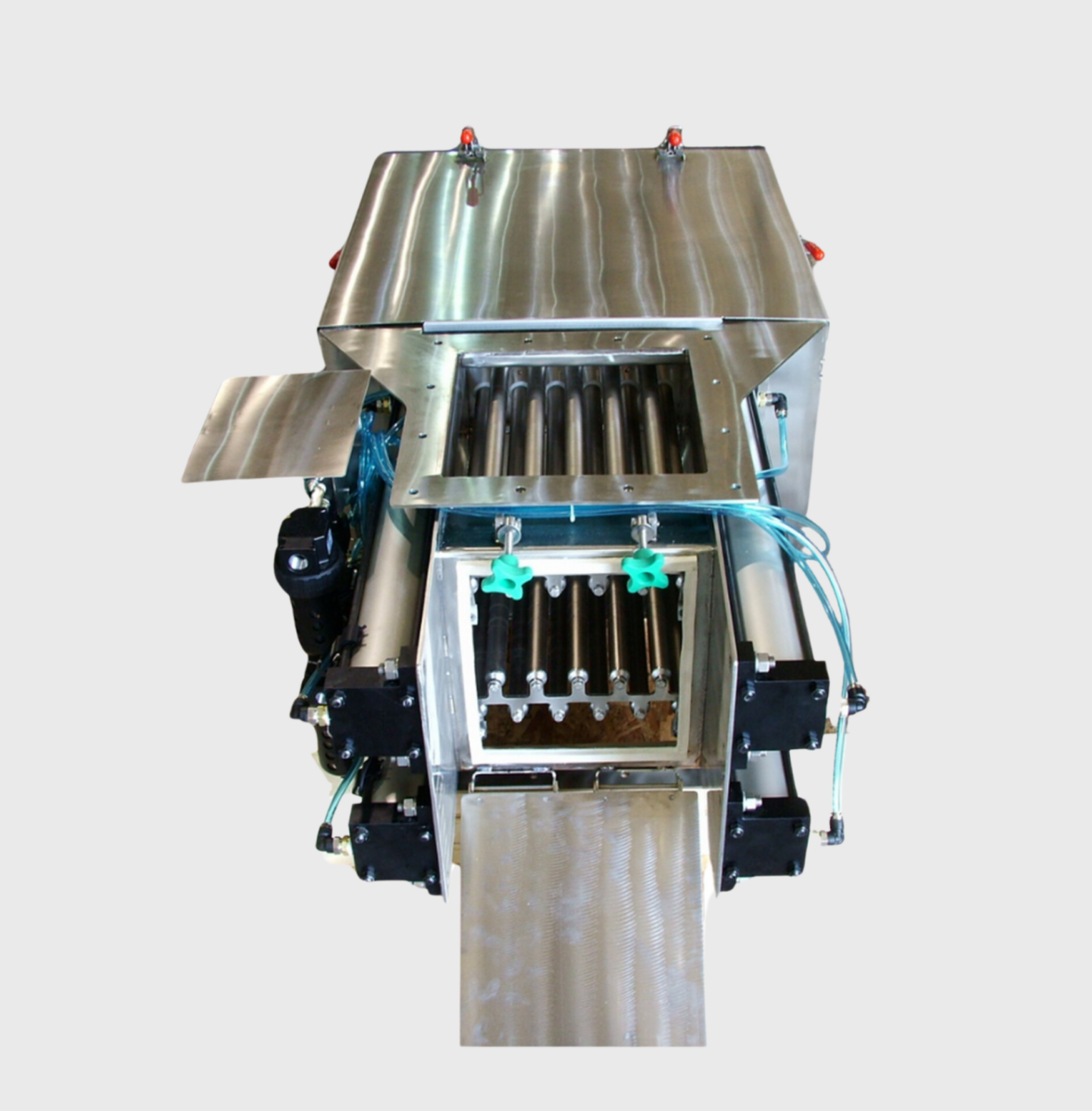

The product passes through a series of magnetic tubes purposefully designed to create an exceptionally efficient magnetic circuit. Each row of magnetic tubes is staggered to prevent product bridging or choking, optimizing magnetic filtration. As tramp metal contaminants cling to the magnetic tubes, pneumatically controlled cylinders operate one double bank drawer of magnetic tubes at a time to extract the tramp metal from the product stream safely. This design allows one drawer to clean while the other continues filtering the product stream, enabling uninterrupted flow. The robust cleaning cycle seamlessly supports the flow design. After the solenoid is manually or electrically actuated, the cylinders retract, drawing the magnetic tubes through the stripper assembly to dispose of the collected tramp iron outside the product flow area. The cylinders then return to the operational position, pushing the magnetic tubes back through the stripper assembly into the housing.

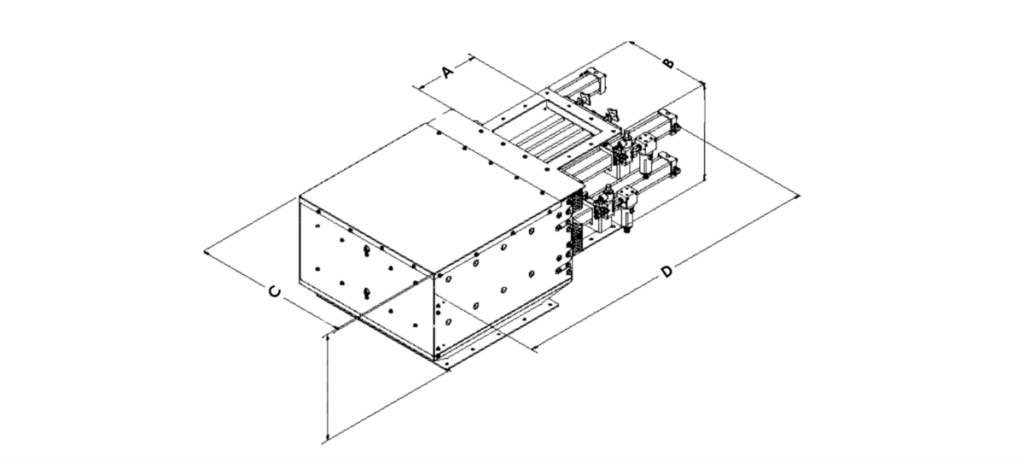

One Inch Tube Continuous-Clean Drawer Magnet Specification Table

US Customary Units

| 1" CONTINUOUS-CLEAN DMU MODEL # | (A) PRODUCT FLOW OPENING AREA (IN.2) | (B) FLANGE WIDTH (IN.) | (C) OVERALL WIDTH (IN) | (D) OVERALL LENGTH (IN.) | # OF MAGNETIC TUBES (4 ROWS) | APPROX. WEIGHT (LBS.) |

|---|---|---|---|---|---|---|

| CFDMU-408-SC | 8 | 12.25 | 25.2 | 49.5 | 14 | 421 |

| CFDMU-410-SC | 10 | 14.25 | 27.2 | 53.5 | 18 | 469 |

| CFDMU-412-SC | 12 | 16.25 | 29.2 | 57.5 | 22 | 517 |

| CFDMU-414-SC | 14 | 18.25 | 31.2 | 61.5 | 26 | 565 |

| CFDMU-416-SC | 16 | 20.2510 | 33.2 | 65.5 | 30 | 613 |

| CFDMU-418-SC | 18 | 22.25 | 33.2 | 69.5 | 34 | 661 |

| CFDMU-420-SC | 20 | 24.25 | 35.2 | 73.5 | 38 | 709 |

One Inch Tube Continuous-Clean Drawer Magnet Installations and Variations

1" Continuous-Clean Drawer Magnet for Grain Processing Plant with 24/7 Processing

1" Continuous-Clean Drawer Magnet for Bridge-Prone Pellet Manufacturing

1" Continuous-Clean Drawer Magnet Designed for High-Volume Food Plant