Remove Both Large and Small Tramp Metal

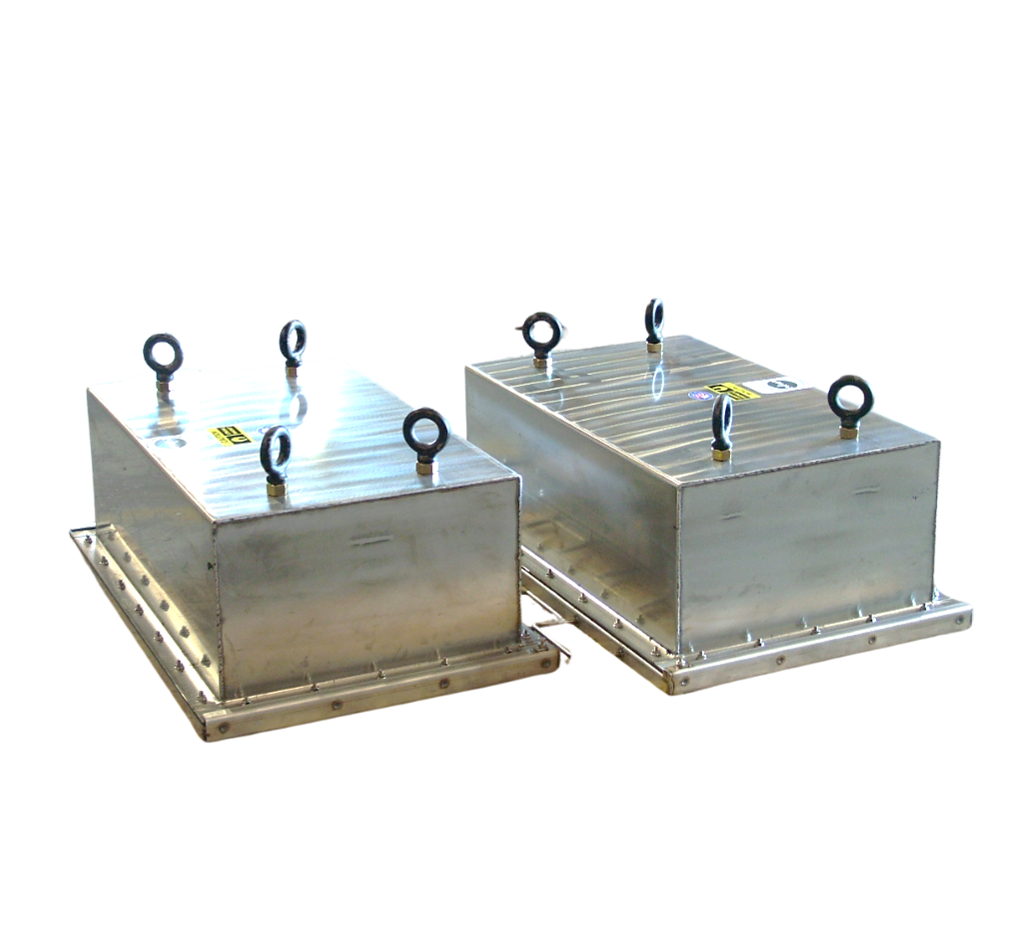

MPI’s Quick-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet/Cross Belt Separator delivers high-performance metal separation with a time-saving cleaning mechanism for conveyor applications. Designed to capture and remove ferrous contaminants from conveyed material, this unit is ideal for industries such as recycling, mining, aggregate, and bulk material handling. The quick-clean feature allows operators to efficiently remove collected metal with minimal effort, reducing downtime and maximizing productivity.

Engineered for heavy-duty operation, this suspended plate magnet features a rugged stainless-steel construction and powerful magnetic circuit, ensuring reliable performance in demanding environments. The hinged cleaning mechanism enables quick access to the magnetic surface, making routine maintenance fast and efficient. With its ability to effectively remove metal contaminants from product flows, the Quick-Clean RBM Plate Magnet enhances equipment longevity, protects processing machinery, and ensures product purity. All MPI Plate Magnets are Intell-I-Mag® Compatible.

Benefits of the Quick-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet From Magnetic Products, Inc

-

High-Performance Magnetic Separation

Equipped with powerful permanent plate magnets, MPI’s RBM effectively captures and retains tramp metal, preventing contamination in processing lines. The strong magnetic field ensures efficient separation, safeguarding downstream equipment and maintaining product purity across various industries, including food, plastics, and bulk material handling.

-

Multiple Cleaning Options

Available in manual, quick-clean, or self-cleaning designs, operators can choose the best option for their workflow and maintenance schedule. The quick-clean mechanism simplifies metal removal, reducing downtime and minimizing labor requirements. Self-cleaning models automate the cleaning process, improving operational efficiency in high-volume applications.

-

Durable Construction

Built to withstand demanding industrial environments, MPI’s RBM is available in standard and abrasion-resistant models. The abrasion-resistant option includes hardened steel construction and specialized coatings, ensuring longevity even when handling glass, minerals, or rough aggregates.

-

Optimized for Different Flow Systems

Designed to integrate with various material handling systems, including gravity-fed chutes, conveyor-mounted setups, and enclosed processing applications. Customizable configurations ensure optimal metal separation across different material flow rates and product types.

-

Enhanced Contaminant Removal

Stepped plate magnet designs increase metal retention efficiency by preventing metal “wash-off,” a common issue in high-speed product flows. This feature ensures captured contaminants remain securely in place until removal, improving separation performance and reducing product recontamination risks.

-

Customizable Housing & Finishes

It is available with dust-tight enclosures, stainless steel construction, and FDA-compliant finishes, making it suitable for hygienic environments such as food processing and pharmaceutical applications. Various inlet and outlet sizes, flanges, and mounting options can be tailored to fit specific installation requirements.

-

Simple Installation & Integration

The compact and modular design allows easy retrofitting into existing processing lines without significant modifications. It is also designed for seamless integration with MPI’s Intell-I-Mag® monitoring system, which provides real-time performance tracking and maintenance alerts.

-

Extended Equipment Lifespan

It effectively removes damaging metal debris, reducing machine wear and preventing costly breakdowns. It also helps protect grinders, crushers, mills, and other sensitive equipment from premature failure, resulting in lower maintenance costs and improved production efficiency.

Quick-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet Product Details

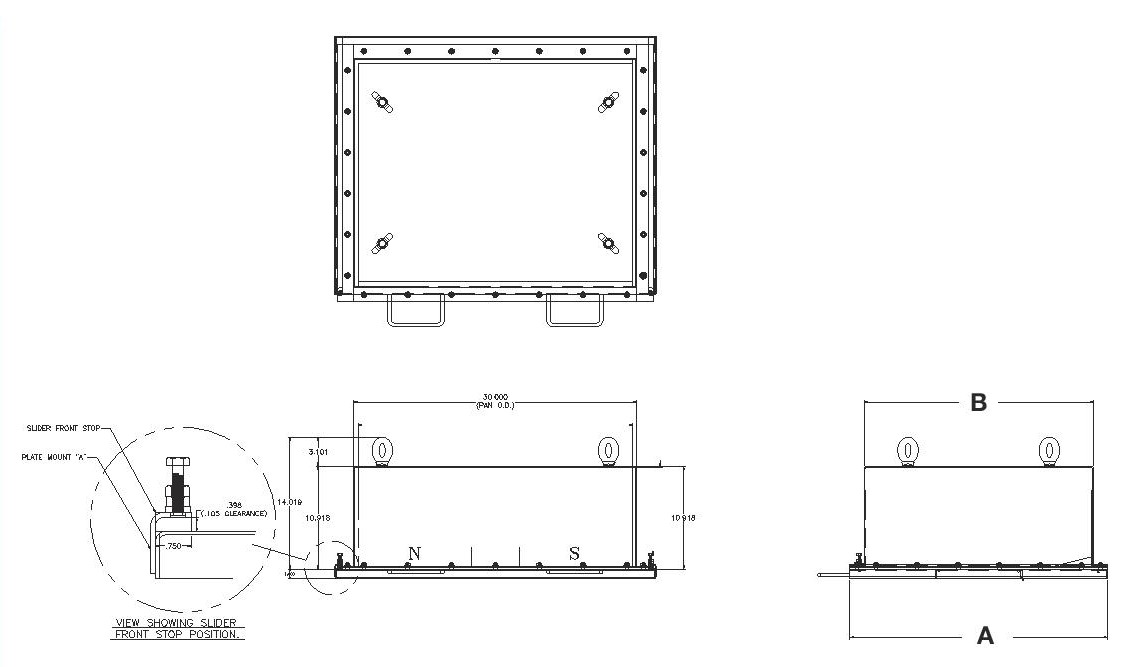

Optimal Magnet Positioning

- The Quick-Clean Suspended Permanent Magnet is mounted above the conveyor belt, positioned approximately 5”–8” above the product stream for effective tramp metal removal (8”–10” with the bucking option).

- To maximize efficiency, the magnet should be installed in an easily accessible area, ensuring safe and convenient cleaning.

- The magnet must be positioned away from conveyor components such as idler rollers or support plates to prevent unintended magnetization, which can cause excessive wear on the conveyor system.

Magnetic Separation Process

- As material moves along the conveyor, ferrous contaminants, including screws, bolts, nails, and metal fragments, are attracted to the powerful suspended plate magnet.

- The tramp metal accumulates across the entire magnetic face, significantly increasing retention capacity before cleaning is necessary.

- The system is designed to operate efficiently with conveyor speeds of up to 250 feet per minute, maintaining high-performance tramp metal removal.

Cleaning the Magnet (Quick-Clean Mechanism)

- To clean the magnet, the operator grabs the handle on the quick-clean stripper and pulls it toward them until it reaches the stop.

- As the stripper is pulled, the captured metal debris is released and falls away from the magnet into a designated collection area.

- Once all metal has been removed, the stripper's face is slid back into place, restoring the magnet to full operational readiness.

System Benefits

- Efficient Metal Removal – Ensures continuous tramp metal separation, reducing contamination and equipment damage.

- Easy Maintenance – Quick-clean design minimizes downtime by enabling fast and effortless cleaning.

- Extended Magnet Performance – The large magnetic face increases metal retention, reducing the frequency of cleaning cycles.

- Versatile Installation—It can be customized to meet specific operational requirements, including different suspension heights and optional bucking configurations.

MPI’s Quick-Clean Suspended Permanent Magnets are engineered for reliable and long-lasting performance. They provide a highly effective, low-maintenance solution for protecting processing systems and ensuring high product quality.

Quick-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet Specification Table

US Customary Units

| MODEL # | (A) BELT WIDTH (IN.) | (B) OVERALL LENGTH (IN.) | APPROX. WEIGHT (LBS) |

|---|---|---|---|

| RBM - 18 | 24 | 18 | 950 |

| RBM - 24 | 30 | 24 | 1300 |

| RBM - 30 | 36 | 30 | 1600 |

| RBM - 42 | 42 | 36 | 1900 |

| RBM - 48 | 48 | 42 | 2300 |

Quick-Clean Suspended Receiving Belt Magnet (RBM) Plate Magnet Installations & Variations

Quick-Clean Suspended Receiving Magnet for Asphalt, Aggregate, and Concrete Company

Suspended Receiving Magnet Designed for Conveyed Food Processing Application

Quick-Clean Suspended Receiving Magnet Designed for Recycling Application