Protecting and Moving the World Through Innovation

Protecting and Moving the World Through Innovation

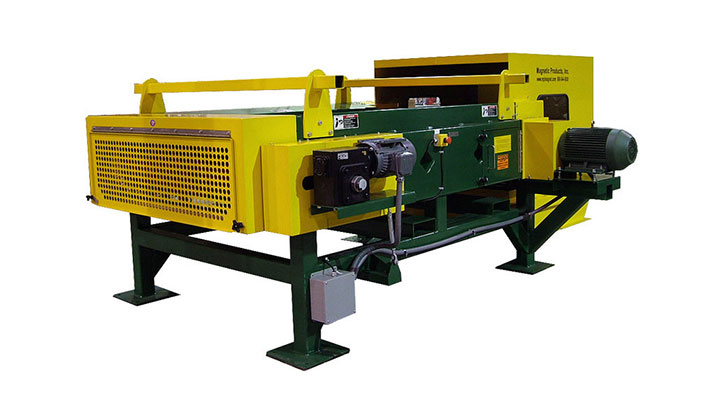

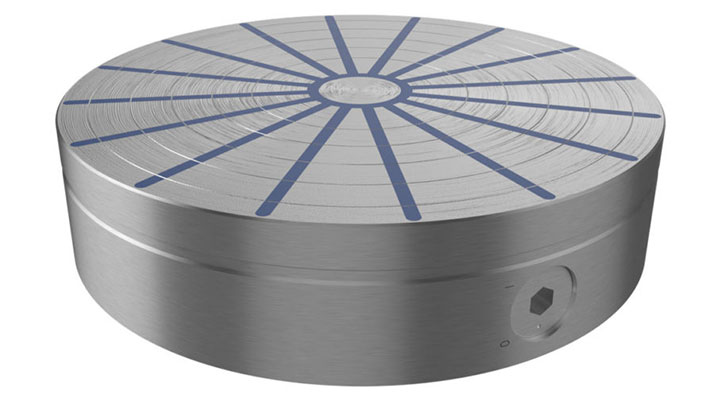

Inspecting and Cleaning Your Magnetic Separator

Regular inspections, cleaning, and maintenance of MPI magnetic separators are essential. This includes, but is not limited to the removal of the collected metal and checking fasteners and seals or other components to ensure they are in proper working condition.

Inspection of the separator is the process of checking the magnetic separator for captured tramp metal and checking fasteners and seals or other components to ensure they are in proper working condition. Cleaning the separator is the process of removing captured tramp metal from the separator. In most cases, inspections will require cleaning the separator and this should be completed before inspection so the working surfaces of the separator can be inspected.

As magnet separation experts, we are often asked questions on how to keep magnetic separation equipment working at peak performance.

- How often should I inspect my magnetic separation equipment?

- How often should I clean my magnetic separator?

- How do I establish an inspection interval?

- How to establish a magnetic separator cleaning schedule?

- How do you inspect your magnetic separator?

- How do you clean your magnetic separation equipment?

- Can my magnet tell me when it needs to be cleaned?

We’ve answered several of the common questions on inspecting and cleaning your magnetic separators to help protect your processing equipment and keep your product pure from tramp metal.

How often should I inspect my magnetic separation equipment? How often should I clean my magnetic separator? How do I establish an inspection interval?

It is important to establish a recommended interval for inspecting and cleaning your magnets based on the amount of tramp metal your operation normally receives. As metal gathers onto the surface of the magnet, the magnetic field is dispersed over a greater surface area, reducing the strength and effectiveness of your separator. Clean magnets will always operate more effectively and a magnet with no tramp metal on the working surface is working at its peak performance. MPI recommends an inspection no longer than eight (8) hours after installation, production run time, or before a product changeover, whichever is first, and every eight hours or sooner thereafter.

Dependent upon the amount of tramp metal collected, the magnetic separator should require inspection more or less frequently, but not exceeding every eight (8) hours of production. Internal standards should be created and followed on what level of tramp metal is acceptable between cleanings, the frequency of cleanings, and how to handle collected tramp metal after each cleaning. These standards may vary from magnet to magnet depending on where it’s located in the facility, its target tramp metal, and its intended purpose. For example, primary, secondary, and finishing magnets or magnets that are installed to either protect processing equipment or purify a product, may all have different standards established.

If the magnetic separator is saturated with tramp metal over the established standard (For example, 20% of the magnet’s working surface is covered, a thickness of 1-2mm thick on the separator, or 20 grams of metal), the interval between inspections should be reduced by half until an acceptable level is achieved. If there is little or no tramp metal collected, the cleaning interval may be increased by half until an acceptable level is achieved. In most cases, tramp metal is not present at a consistent rate, for example, an equipment failure or contaminated product from a vendor. Therefore, surges of metal are more likely, and why it is always best to inspect your magnet more frequently, even if captured metal contamination is consistently low.

How to establish a magnetic separator cleaning schedule?

- After installation, inspect your magnet after the first hour of production

- If an insignificant amount of metal is observed, return in two (2) hours to inspect magnet

- If magnet continues to have insignificant amount of tramp metal, it is recommended that maximum time between cleaning is eight (8) hours

- If significant amount of metal is found on magnet, increase the cleaning interval as required to ensure the magnet does not reach maximum tramp metal capacity

How do you inspect your magnetic separator? How do you clean your magnetic separation equipment?

Depending on the type of magnetic separation equipment used, the method to clean the separator and areas to inspect will vary. MPI product manuals cover the specific steps required for each type of magnetic separation product. Reference the correct product manual for your separator.

NOTE:

- The product flow should always be stopped before cleaning the product. This will reduce the risk of re-contaminating the product with any removed metal.

- All inspections and cleanings should be logged. Reference MPI’s pull test kit manual for a sample form.

WARNING:

![]() Always use heavy-duty cut-proof work gloves and adequate protection when handling dirty or contaminated drawer magnets. The metallic particles collected by these magnets are extremely fine and can penetrate the skin, clothes, and even some work gloves, possibly causing severe irritation and discomfort.

Always use heavy-duty cut-proof work gloves and adequate protection when handling dirty or contaminated drawer magnets. The metallic particles collected by these magnets are extremely fine and can penetrate the skin, clothes, and even some work gloves, possibly causing severe irritation and discomfort.

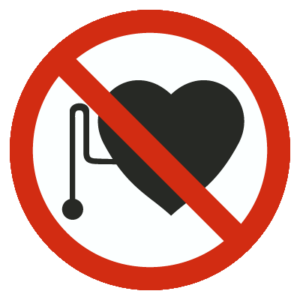

Keep sensitive electronic equipment and anyone using a pacemaker away from, and at a safe distance from, the magnets used in MPI equipment at all times. Sensitive equipment may include but is not limited to smartphones, smart watches, pacemakers, and magnetic media such as computer drives, credit cards, and magnetic tape.

Keep sensitive electronic equipment and anyone using a pacemaker away from, and at a safe distance from, the magnets used in MPI equipment at all times. Sensitive equipment may include but is not limited to smartphones, smart watches, pacemakers, and magnetic media such as computer drives, credit cards, and magnetic tape.

Can my magnet tell me when it needs to be cleaned?

YES! Traditional magnetic separation equipment has been “dumb”, operators have to shut down their equipment and check them at set intervals. Intell-I-Mag® is the first magnetic separator that is “intelligent”. It tells you when the magnet needs to be cleaned, or, just as important, when it doesn’t.

Learn More about Intell-I-Mag®

Metal Control Systems Audit

It is MPI’s mission to support food manufacturers in promoting food safety and consumer protection. It’s no secret that Food Safety Modernization Act (FSMA) compliance is a main focus for food manufacturers today, which is why MPI is dedicated to being the only choice in complete metal control for food manufacturing facilities.

In addition to being MPI certified Metal Control System Auditors, our entire Regional Management Team has also been HACCP certified, enabling us to provide the most knowledgeable assistance in the industry with regard to food safety. We believe that earning this certification allows our team to provide more value to our customers, adds an additional layer to our audit program, and demonstrates our dedication to upholding industry standards and education on this important topic.

MPI accomplishes all this through customer education and Metal Control System Audits. These regularly conducted audits provide a comprehensive picture of a facility’s metal control system and provides proof of HACCP compliance and required documentation.

Schedule an Audit or Assessment

MPI's Magnetic Pull Test Kit

MPI’s Magnetic Pull Test Kit is the most accurate and easiest method to test the strength of your magnets. This easy-to-use, compact gauge fits into tight areas and is battery-operated (four AA batteries included.). Boasting a capacity of 44 lbs. (20 kg), MPI’s magnetic pull test kit can measure pull in pounds, ounces, kilograms, newtons, or kilonewtons. It can maintain the last reading after release. Packaged in a hard-sided foam-padded carrying case, this compact unit includes all needed accessories and can be used to test a complete range of magnet types and configurations. The documentation generated from this test can be used for compliance in a Hazard Analysis and Critical Control Point (HACCP) plan or for documentation requirements under the Food Safety Modernization Act (FSMA).