Metal Control Solutions for the Molded and Extruded Plastics Industry

Plastic manufacturing involves high-volume handling of raw resins, additives, and regrind material, often through gravity-fed, pneumatic, or vacuum conveying systems. Tramp metal can be introduced from:

- Incoming resin shipments

- Grinder/granulator wear

- Material regrind contamination

- Pneumatic conveying and line abrasion

- Wear of processing equipment

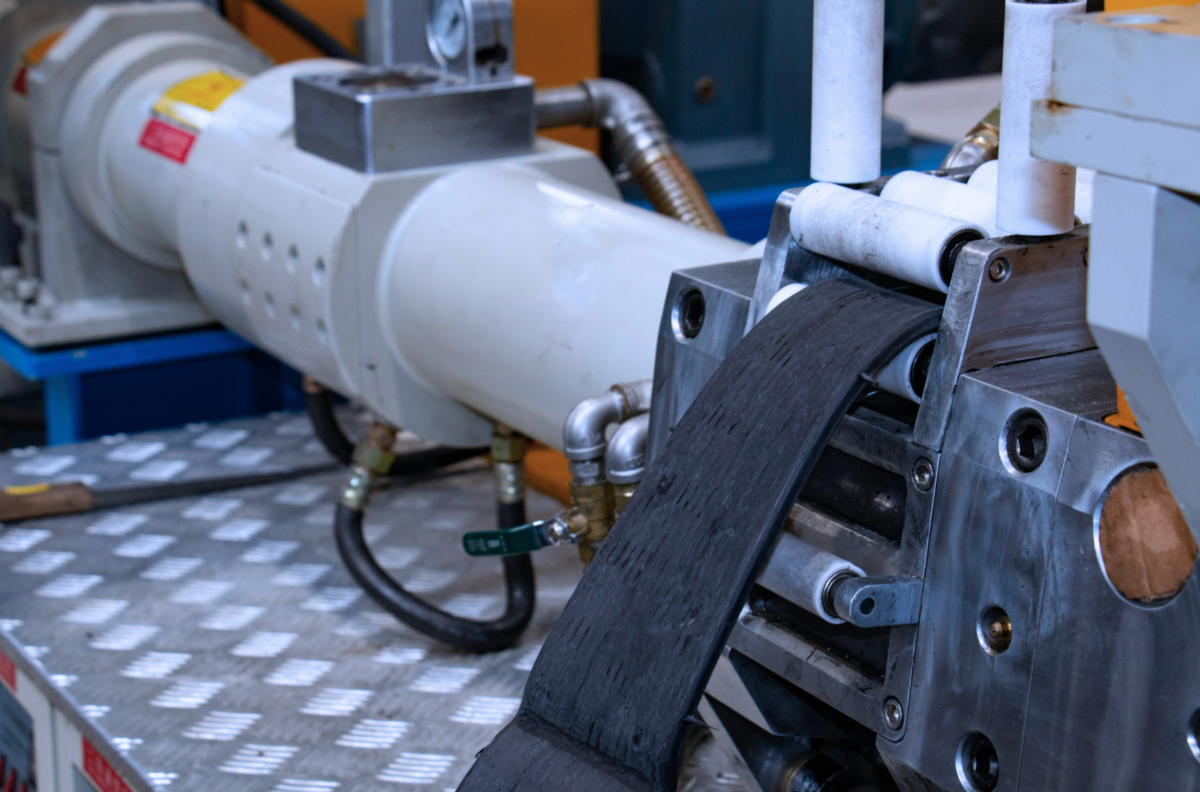

Even trace amounts of metal contamination can damage screws, barrels, nozzles, dies, and tooling, leading to costly downtime and defective molded parts. MPI’s magnetic separation solutions are engineered to capture ferrous and weakly magnetic contaminants before they reach extrusion, injection, or blow molding machines.

MPI helps plastics manufacturers achieve clean, efficient, and damage-free production by removing metal contaminants from virgin, recycled, or blended resin streams. Whether your plant handles high-throughput molding, multi-material extrusion, or food-grade packaging production, MPI provides:

- Maximum equipment protection

- Improved part quality

- Reduced maintenance downtime

- Compliance with food/medical standards

- Material reclamation efficiency

- Smooth production with fewer line stoppages

Turnkey Solutions for Molded and Extruded Plastics From Magnetic Products, Inc

-

Protects Critical Processing Equipment

MPI magnetic separators remove tramp metal that could otherwise damage high-value components such as extruder screws, hot runners, and molds.

-

Reduces Downtime and Maintenance

By capturing debris early, MPI solutions prevent system clogs and tool wear, reducing unplanned service and extending equipment lifespan.

-

Maintains Material Purity and Part Quality

Metal in plastic can cause streaks, burn marks, voids, or structural weaknesses. MPI systems keep resin, and additives clean for flawless finished parts.

-

Supports Regrind and Closed-Loop Systems

Contaminant removal is especially important when reprocessing scrap or incorporating recycled material into production—MPI keeps regrind clean and safe.

-

Customizable for Any Conveying Method

Available in gravity-fed, pneumatic, or inline vacuum line designs, MPI solutions fit seamlessly into plastic processing workflows without compromising throughput.

-

Tool-Free Quick Cleaning and Maintenance

Fast-access drawers and self-cleaning options reduce labor and support frequent color/material changeovers without extended downtime.

-

Food-Grade Options for Medical and Packaging Applications

MPI offers polished housings, sanitary seals, and FDA-compliant construction for plastic parts used in food contact or medical environments.

-

Compact, Modular Designs

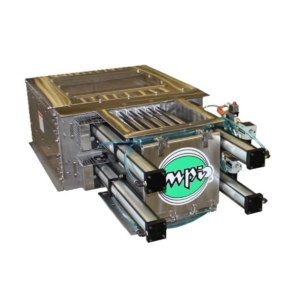

Space-saving MPI units integrate easily above hoppers, dryers, blenders, or feeder necks, and are compatible with most central conveying systems.

How Does the Molded and Extruded Plastics Industry Use Magnets?

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

| Drawer-In-Housing Magnets (Manual-Clean, Quick-Clean, Self-Clean) | Above hoppers, day bins, or vacuum receivers | Removes large tramp metal (wrenches, rebar, bolts) before it reaches crushers or screens | Before entry into extruders or molding machines | High-strength magnetic tubes filter contaminants as material passes through |

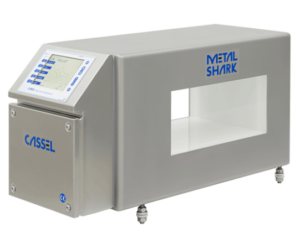

| Pneumatic Line Drawer Magnets (Quick-Clean, Self-Clean) | Inline with pressurized or vacuum-conveying systems | Capture fine metal from high-speed material transfers. Continuous protection without disrupting conveying. | Between central material handling and processing machines | Magnetic cartridges attract particles during in-line flow |

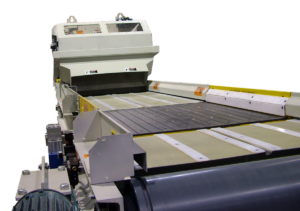

| Plate Magnets and Hump Magnets | Gravity chutes, dryer outlets, or blender discharges | Ideal for larger ferrous pieces in bulk plastic flows. Simple, durable protection in high-volume gravity applications. | During raw resin feeding or additive blending | Material flows over magnetic plate; metal is held until cleanout |

| Pneumatic Line Magnets | Inside vertical pipelines and vacuum lines | Offer low-pressure drop in high-flow systems. Ideal for pneumatic or central conveying applications. | Before entry into silos, mixers, or vacuum receivers | Conical magnetic core intercepts contaminants in vertical drop or suction |

| Liquid Trap Magnets | For specialty plastics using plasticized or resin slurry | Capture metal from liquid resin or paste material. Protects pumps and dies from metal in viscous plastic mediums. | In plasticizing systems or pump-fed mixing setups | Magnetic tubes in sealed housing remove debris during flow |

| Magnetic Head Pulleys | At conveyors handling plastic flake or crushed scrap | Automatically removes ferrous from regrind stream. Ensures regrind quality and reusability. | During reclaim, recycling, or closed-loop production | Pulley magnet attracts and discharges metal from flowing product |