Metal Control Solutions for the Textiles and Non-Woven Materials Industries

In the textiles and non-woven materials industry, stray metal contamination, like broken needles, staples, wire fragments, or fasteners, can wreak havoc on delicate production lines. MPI’s magnetic separation and detection systems are strategically placed throughout processing to safeguard machinery, protect operators, and ensure product quality.

Metal enters the process through raw material bales, recycled fiber blends, maintenance tools, or wear-and-tear in equipment. MPI products are used at critical stages:

- Fiber intake and blending – to intercept metal before it damages carding machines

- Carding, needle punch, or hydroentangling – where trapped metal can jam or ruin expensive machines

- Finishing, coating, lamination, and converting – to avoid surface damage and ensure defect-free output

- Slitting and rewinding – to detect and reject any contaminated rolls before shipping

Whether producing textiles for apparel, automotive, hygiene, filtration, or insulation, MPI systems provide reliable, low-maintenance metal removal designed for high-throughput, fiber-rich, and dust-laden environments.

With MPI solutions in place, textile and non-woven manufacturers gain:

- Equipment protection from downtime and catastrophic damage

- Consistent product quality in high-spec industries like hygiene, filtration, or automotive

- Improved operator safety and compliance with quality assurance protocols

- Efficient, dust-tolerant separation for facilities handling natural or synthetic fibers

MPI keeps the fiber stream from bale to bolt clean, safe, and flowing.

Turnkey Solutions for Textiles and Non-Woven Materials From Magnetic Products, Inc

-

Protects Precision Textile Equipment

By intercepting ferrous contaminants early, it prevents costly damage to carding heads, looms, felting bars, and calendar rolls.

-

Enhances Product Purity and Appearance

Eliminates visible metal specks, fiber tears, and surface defects, supporting high-quality output for sensitive or decorative applications.

-

Supports Worker Safety and Operator Confidence

This reduces the risk of injury from hidden sharp objects in rolls, webs, or fiber bales, especially during handling or changeovers.

-

Designed for Dusty, Fluffy Environments

Built with fiber-resistant coatings, sealed housings, and low-turbulence designs to stay effective in lint-heavy air and materials.

-

Quick-Clean and Self-Clean Options Minimize Downtime

Tool-free access and automated self-cleaning designs allow regular maintenance without disrupting production.

-

Compact and Flexible for Easy Integration

MPI systems fit easily into chutes, pneumatic lines, and conveyor systems, supporting retrofits or new installations with minimal reengineering.

-

Optimized for Natural, Synthetic, and Recycled Fibers

Configurable for cotton, polyester, rayon, glass fiber, melt-blown webs, and mixed-material streams.

-

Improves Operational Efficiency and Yield

MPI solutions increase uptime and throughput across the plant by avoiding mechanical failures and reducing material waste.

How Does the Textile and Non-Woven Materials Industry Use Magnets?

US Customary Units

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

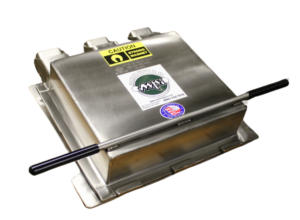

| Drawer Magnets / Hump Magnets | Under bale openers, before carding heads | Captures staples and debris from raw fiber; tool-free cleaning supports fast changeovers | Raw material intake | Remove staples, wires, and tramp metal from loose or baled fiber |

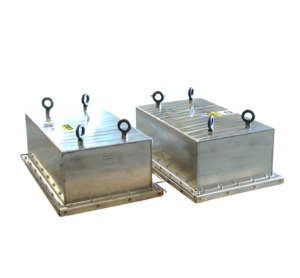

| Plate Magnets / Magnetic Chutes | Gravity-fed hoppers and fiber transport chutes | Passive, high-strength magnetic separation during fiber flow | Raw material intake / Web forming / felting | Extract debris before it reaches sensitive rollers or felting systems |

| Pneumatic Line Magnets | Pneumatic fiber lines | Intercepts contaminants in high-speed fiber transfer without impeding flow | Pneumatic transfer | Clean ferrous fines from high-velocity fiber transport lines |

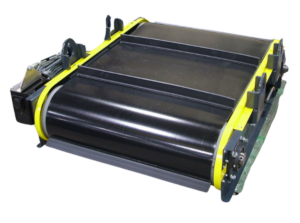

| Magnetic Head Pulleys | At conveyor discharge (roll handling) | Automatically separates metal before downstream slitting or rewinding | Finishing and converting | Separate residual metal from roll ends, scrap, or trim |

| Drum Separators | In reclaim or edge trim lines | Separates metal from fiber scrap before reintroduction to production | Finishing and converting | Separate residual metal from roll ends, scrap, or trim |

| Metal Detectors (Conveyor Style) | Before rewinding or shipping | Detects any remaining metal contamination in finished non-woven webs | QA inspection points and final inspection | Verify metal-free status of finished non-woven rolls or fabric bolts |

| Magnetic Conveyors (Beltless) | Below needle punching or hydroentangling presses | Transports metal debris away from processing areas safely and efficiently | QA inspections points and final inspection | Verify metal-free status of finished non-woven rolls or fabric bolts |