Highest Performance Technology

The MPI Compact Gravity Feed Metal Detector is specifically engineered for space-restricted processing environments where contaminant detection is critical, but installation height is limited. This high-performance, low-profile system offers precise detection of ferrous, non-ferrous, and stainless-steel contaminants in free-falling, dry bulk materials such as powders, spices, grains, and granulates. Built with hygienic stainless-steel construction and a fast-reacting reject system, the compact model is ideal for food, pharmaceutical, chemical, and plastics industries. Despite its reduced height, it delivers the same advanced detection capabilities as full-size models—ensuring product purity, equipment protection, and regulatory compliance without compromising valuable production space.

Benefits of the Compact Gravity Feed Metal Detector From Magnetic Products, Inc

-

Low-Profile Design for Tight Spaces

Engineered with a minimal installation height, it’s perfect for gravity-feed lines with limited vertical clearance—ideal for retrofits or compact plant layouts.

-

High-Sensitivity Metal Detection

Using advanced signal processing, it detects ferrous, non-ferrous, and stainless-steel contaminants with exceptional accuracy, even in small particle sizes.

-

Hygienic Stainless-Steel Construction

Built to meet food and pharmaceutical sanitation standards, with smooth, crevice-free surfaces for easy washdown and contamination control.

-

Fast-Acting Auto-Reject Mechanism

An integrated diverter or flap system quickly removes contaminated products with minimal waste, preserving throughput and line efficiency.

-

User-Friendly Digital Controls

Intuitive touchscreen interface with automatic product learning, calibration, and reject timing settings for simplified operation and reduced setup time.

-

Easy Integration into Existing Systems

Designed for vertical drop chutes, the unit includes mounting options and adapter kits for seamless connection to upstream and downstream equipment.

-

Reduced Downtime and Easy Maintenance

Quick-access components and tool-free disassembly simplify cleaning, routine checks, and part replacement.

-

Supports HACCP and Quality Programs

Includes reject logging, performance monitoring, and optional validation ports to comply with food safety and audit requirements.

Compact Gravity Feed Metal Detector Product Details

The MPI Compact Gravity Feed Metal Detector is designed for vertical drop sections in gravity-fed systems where dry, free-flowing materials are conveyed without additional pressure or assistance. As products move through the metal detector's coil assembly, they enter a precise electromagnetic field.

If this electromagnetic field is disrupted by ferrous, non-ferrous, or stainless-steel contaminants, an immediate signal is sent to the control unit. The system then activates a rapid response reject mechanism, such as a swing gate or diverter valve, directing the contaminated material into a dedicated reject bin or chute.

With its compact design, the detector ensures seamless operation without interrupting product flow, while advanced filters and signal algorithms help to reduce false rejects. The operator interface supports multiple product setups and includes validation test reminders to maintain consistency and adherence to food safety standards.

Bulk materials fall through the metal detector when installed in a gravity feed pipeline. Should any metallic contaminants, whether magnetic or non-magnetic, be detected, the reject flap immediately engages to separate and remove the impurities from the product stream.

Gravity Feed Metal Detector

Specifically for free-falling powders and bulk products.

Once positioned in a gravity feed pipeline, the metal detector allows bulk materials to pass through uninterrupted. If a metallic contaminant is identified, the reject flap activates to swiftly detach and extract it from the product flow.

The METAL SHARK® Gravity Feed (GF) Metal Detectors come in standard and compact models and function in gravity feed pipelines to identify undesired metal contaminants in continuously flowing granular or powder products, including sugar, flour, cornmeal, and spices.

All product-contacting components are manufactured to comply with FDA food-grade quality standards. As bulk material flows through the detector, the reject flaps remove even the smallest metallic contaminants from the stream.

With a maintenance-free design and robust construction, this detector promises reliable performance even in demanding industrial settings. It is available for pipe diameters ranging from 1/2″ to 24″, with options for ATEX Zone 21 and 22 compliance.

The Metal Detector GF is frequently utilized for:

-

Powdered milk

-

Sugar

-

Cereal

-

Proteins

-

Spices

-

Granules

Constructed from 100% stainless steel, the Metal Detector GF is specially designed for the food industry.

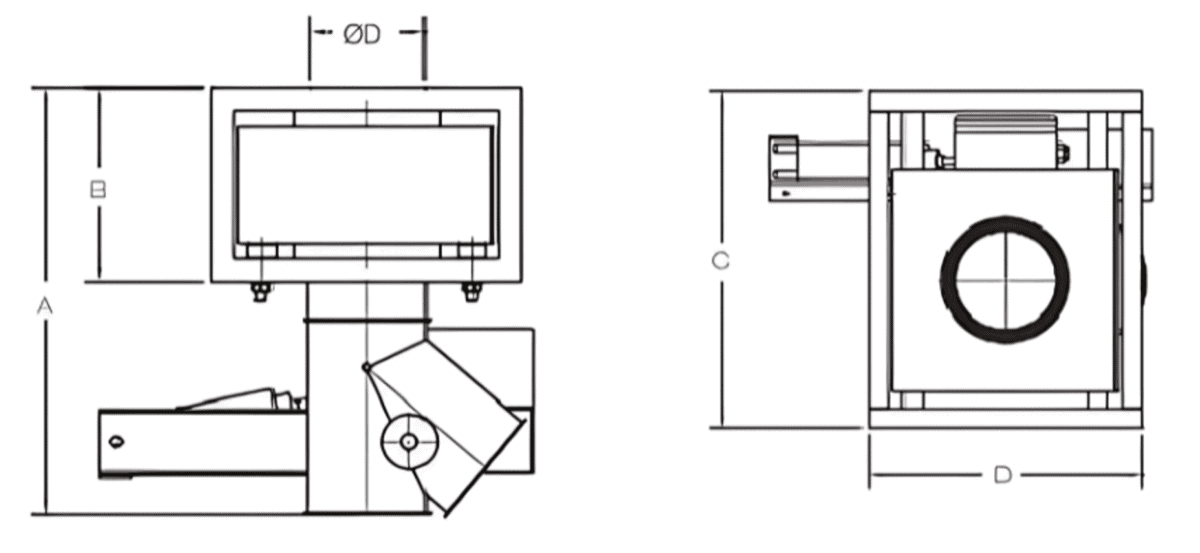

Compact Gravity Feed Metal Detector Specification Table

US Customary Units

| MODEL # | DIA. FLOW OPENING (OD) (IN.) | (A) OVERALL HEIGHT (IN.) | (B) MD HEIGHT (IN.) | (C) MD WIDTH (IN.) | (D) MD DEPTH (IN.) | TYPICAL MATERIAL FLOW RATE (FT³/HOUR) | FE SENSITIVITY (IN.) | AI SENSITIVITY (IN.) | SS SENSITIVITY (IN.) |

|---|---|---|---|---|---|---|---|---|---|

| GF0100C | 4 | 17.7 | 7.8 | 17.7 | 12.5 | 700 | 0.028 | 0.039 | 0.043 |

| GF0120C | 5 | 20.9 | 9.8 | 17.7 | 13.3 | 1000 | 0.039 | 0.047 | 0.055 |

| GF0150C | 6 | 23.6 | 9.8 | 19.8 | 15.8 | 1500 | 0.043 | 0.059 | 0.071 |

| GF0200C | 8 | 35.8 | 11.8 | 24.2 | 20 | 2600 | 0.063 | 0.087 | 0.094 |

| GF0250C | 10 | 41.3 | 15.4 | 31.5 | 26 | 4000 | 0.079 | 0.106 | 0.122 |

| GF0300C | 12 | 43.1 | 15.4 | 37 | 31.5 | 5800 | 0.102 | 0.126 | 0.161 |

Compact Gravity Feed Metal Detector Installations & Variations

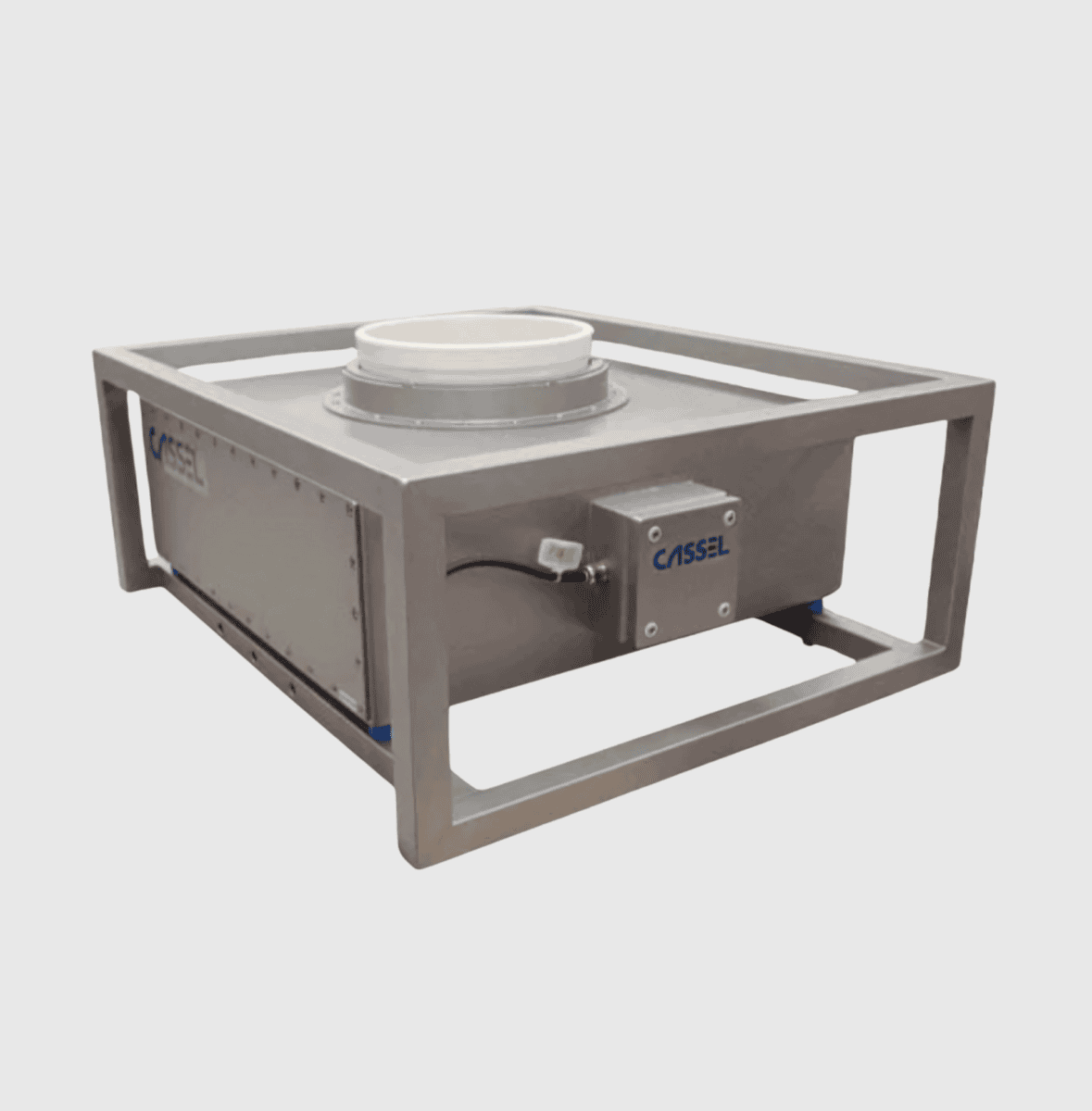

Compact Gravity Feed Metal Detector with Low Assembly Height Designed for Limited Space Application

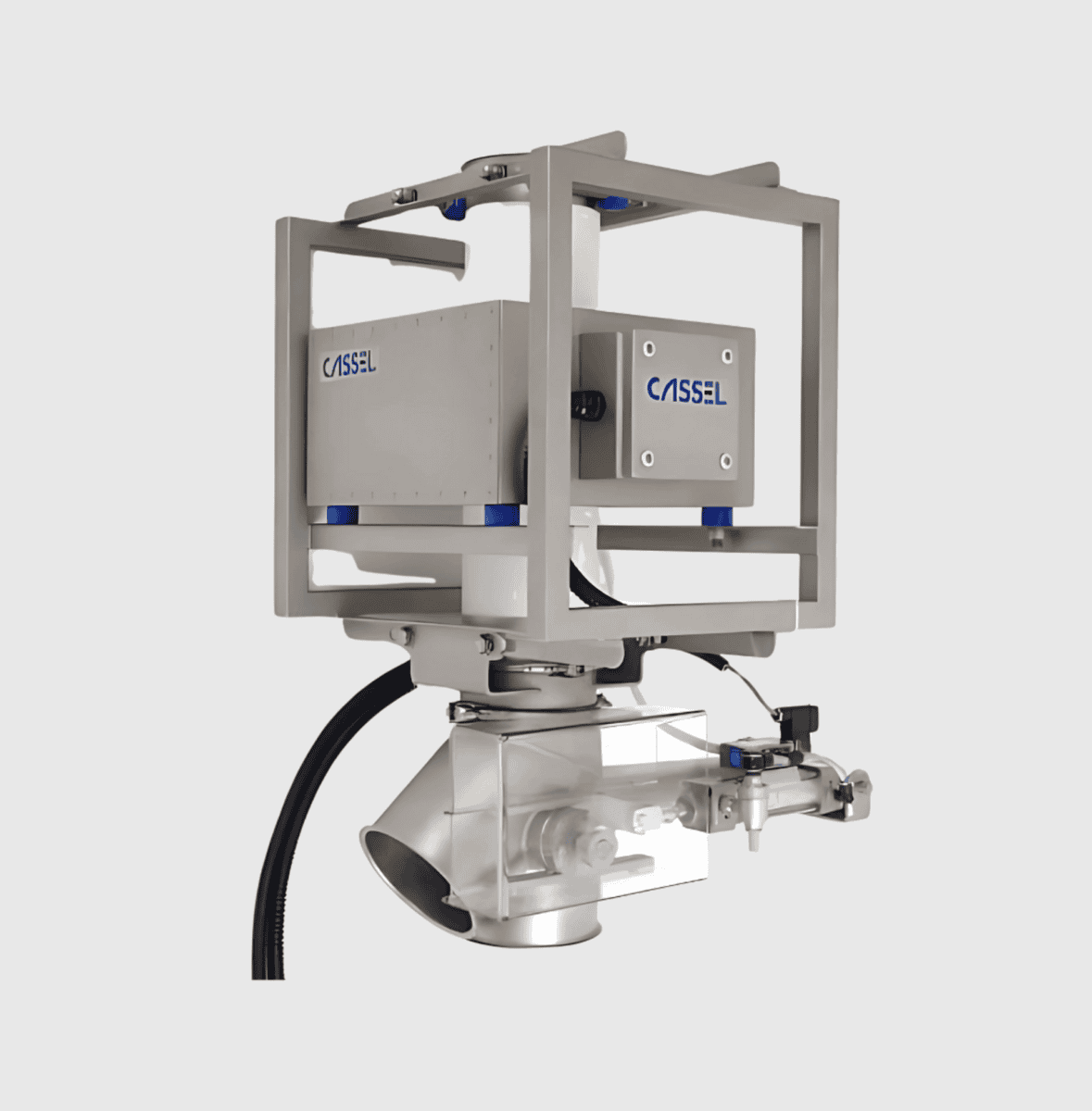

Compact Gravity Feed Metal Detector Mounted for Vertical Pipe Integration

Low Assembly Height Compact Gravity Feed Detector Installed in Limited Height Line