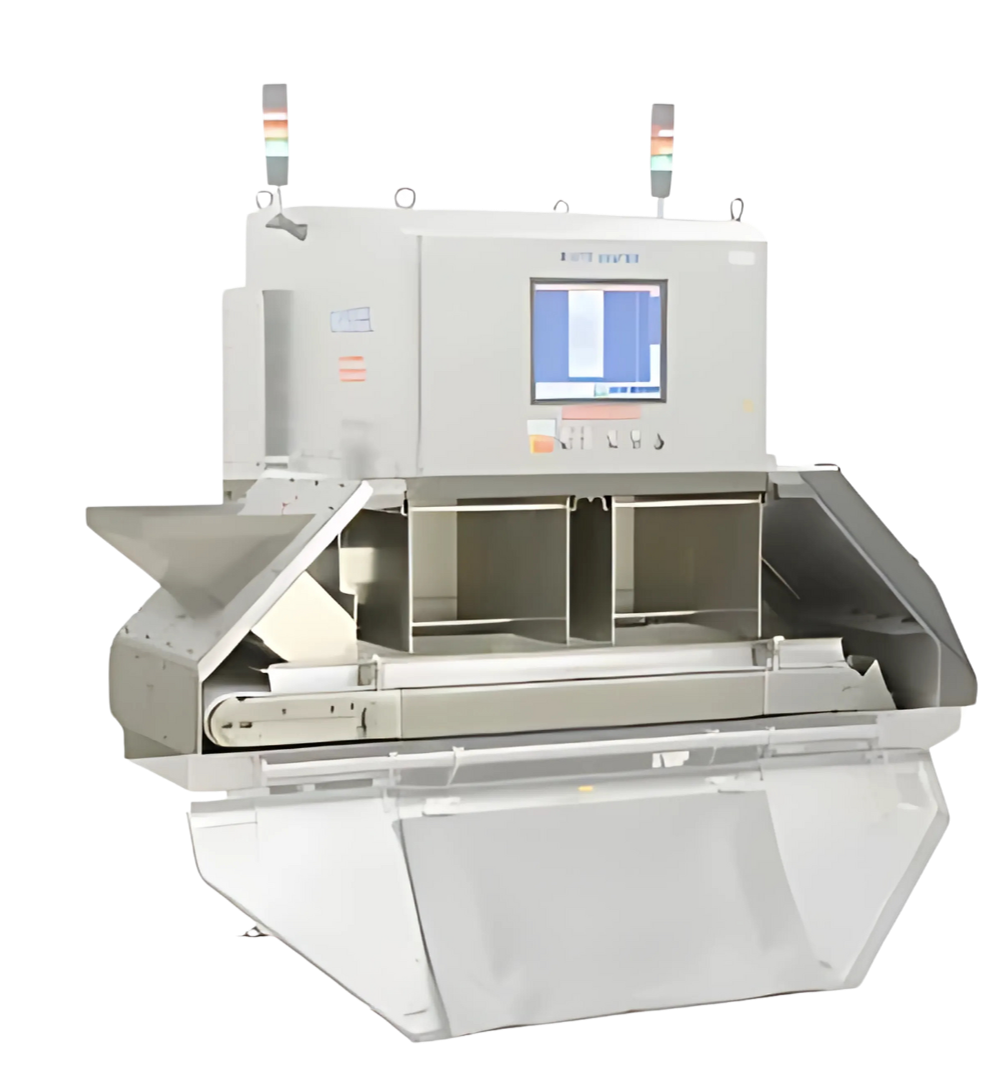

High-Throughput Contaminant Detection for Unpackaged, Free-Flowing Materials

The MPI X-Ray Inspection System for Bulk Products is engineered for continuous, noninvasive inspection of loose, unpackaged materials moving on a conveyor belt, such as powders, granules, flakes, or particulate products. Designed for upstream and midstream applications in food, pet food, chemical, and pharmaceutical processing, this system delivers high-sensitivity foreign material detection without disrupting product flow.

Leveraging advanced dual-energy X-ray technology, the system detects various contaminants, including metal, glass, bone, rubber, and dense plastic—even in small fragments—before the product is packaged. It is ideal for early-stage inspection, where rejecting contaminants minimizes product waste and maximizes operational efficiency.

Built for sanitary washdown environments and customizable for line width, product depth, and reject method. MPI’s bulk X-ray system is critical in preventing downstream contamination, safeguarding equipment, and ensuring final product safety and compliance.

Benefits of the Bulk Product X-Ray Inspector From Magnetic Products, Inc

-

Comprehensive Foreign Object Detection

It detects ferrous and non-ferrous metals, stainless steel, bone, stone, ceramic, glass, rubber, and dense plastics, even in fine or dusty product streams, providing a wider detection range than traditional metal detectors.

-

Designed for Unpackaged Product Streams

It is optimized for loose-flowing materials such as grains, powders, granules, and chopped or shredded food items on conveyor belts. It is perfect for pre-packaging and ingredient inspection points.

-

Advanced Dual-Energy Imaging

Differentiate materials based on atomic density, enabling the reliable detection of low-density contaminants often missed in bulk product environments.

-

High-Throughput Operation

Capable of inspecting bulk material flows at high line speeds (up to 100 meters per minute), ensuring minimal bottlenecks in production lines with continuous product flow.

-

Precision Reject Mechanism Integration

It is compatible with high-speed reject systems such as multi-flap air nozzles, segmented reject belts, or mechanical diverters that remove only contaminated portions of the product stream, reducing waste and maximizing yield.

-

Sanitary, Washdown-Ready Construction

Stainless steel frame and conveyor with sloped surfaces and IP65+ or IP69K enclosures. Built to meet USDA, FDA, and 3-A hygiene requirements in wet or dusty processing environments.

-

Real-Time Inspection with Automated Data Logging

Continuously inspects product flow while logging inspection results, time stamps, rejection events, and image captures, ideal for audits, traceability, and regulatory compliance.

-

Customizable for Product Depth and Line Width

Available in various aperture heights and conveyor widths to accommodate shallow layers or deeper product beds, depending on bulk density and application.

Bulk Product X-Ray Inspector Product Details

MPI’s X-Ray Inspection System for Bulk Products uses a top-down X-ray beam combined with a high-resolution line-scan detector to inspect free-flowing materials conveyed in a continuous stream. The system uses material density contrast to identify foreign objects.

Product Presentation

Unpackaged material is fed onto a conveyor belt in a continuous layer. A product spreader or leveling system may be used upstream to ensure consistent depth and coverage across the belt.

X-Ray Imaging

A low-dose X-ray beam is emitted above and penetrates the entire product layer. The dual-energy detector below captures the X-ray image in real time, measuring differences in material absorption.

Contaminant Identification

The system’s intelligent image processing software analyzes the scanned image for:

- Density anomalies (foreign objects)

- Size, shape, and contrast variations

- Location within the product stream

Contaminant Location & Ejection

When a contaminant is identified:

-

The system pinpoints its location on the belt using timing and position data.

-

A precise reject mechanism (such as air nozzles or pushers) removes the contaminated portion from the stream, without halting flow.

Data Capture & Quality Assurance

Every event is logged with images, timestamps, product ID, and rejection cause. Optional integration with plant networks allows real-time monitoring and compliance reporting.

Bulk Product X-Ray Inspector Specification Table

US Customary Units

| MODEL FEATURE | XRAY SHARK ® XBD10 | XRAY SHARK ® XBD20+ |

|---|---|---|

| X-Ray Source | Single beam x-ray generator with max. 60kV (50W), variable in voltage + current | Single beam x-ray generator with max. 60kV (50W), variable in voltage + current |

| Radiation Leakage | 1 µSv/h or less @ 10cm outside cabinet surfaces | 1 µSv/h or less @ 10cm outside cabinet surfaces |

| Safety | Magnetic safety switches at cabinet doors and tunnel hatches, emergency stop push button, Emergency stop in/out interfaces to safety circuits of production line, x-ray off key switch, PILZ safety circuit | Magnetic safety switches at cabinet doors and tunnel hatches, emergency stop push button, Emergency stop in/out interfaces to safety circuits of production line, x-ray off key switch, PILZ safety circuit |

| X-Ray Detector | low noise 307 mm line scan CCD, diode pitch 0.8 mm, integrated x-ray beam stop | low noise 407 mm line scan CCD, diode pitch 0.8 mm, integrated x-ray beam stop |

| Cooling | Highly efficient, silent DC filter fans | Highly efficient, silent DC filter fans |

| Housing Finish | Stainless steel grade AISI 304 / ISO 1.4301 (CrNi 18/10) | Stainless steel grade AISI 304 / ISO 1.4301 (CrNi 18/10) |

| Degree of Protection | IP54 (according to IEC 60529), including touch panel and fans | IP54 (according to IEC 60529), including touch panel and fans |

| Conveyor Type | Polyurethane belt white (FDA) quick disassembly for cleaning Side guides | Polyurethane belt white (FDA) quick disassembly for cleaning Side guides |

| Conveyor Speed | Conveyor speed by product, 30-60 m/min | Conveyor speed by product, 30-60 m/min |

| Flow Rate | 4 – 25 m³/h for best sensitivity: 1-layer product thickness | 6 - 35 m³/h for best sensitivity: 1-layer product thickness |

| Estimated production sensitivity sphere Ø mm* *depending on application | Metal (execpt aluminuim) 1.0 – 1.5 mm Glass (soda lime) 2.5 – 4.0 mm Ceramic (similar as many stonegrades) 3.0 – 5.0 mm | Metal (execpt aluminuim) 1.0 – 1.5 mm Glass (soda lime) 2.5 – 4.0 mm Ceramic (similar as many stonegrades) 3.0 – 5.0mm |

| Scanning Width | Net scanning width 246 mm | Net scanning width 346 mm |

| Product Memory | 250 different product set-ups | 250 different product set-ups |

| Display | 17“ Color-TFT capacitive Touchscreen | 17“ Color-TFT capacitive Touchscreen |

| Inspection Features | Auto Calibration, Auto adaption to density distribution, Density, Hard Contrast, Soft Contrast, Masking Technology, SuperContrast, SizeFilter, AutoEdge, Images AutoSave/Load, Multi Segment Inspection, Generator Energy by Product, Password protection | Auto Calibration, Auto adaption to density distribution, Density, Hard Contrast, Soft Contrast, Masking Technology, SuperContrast, SizeFilter, AutoEdge, Images AutoSave/Load, Multi Segment Inspection, Generator Energy by Product, Password protection |

| In/Outputs | Programmable outputs (contamination, ready, Emergency Stop) Programmable inputs (Emergency Stop, wake up, optional control signals) | Programmable outputs (contamination, ready, Emergency Stop) Programmable inputs (Emergency Stop, wake up, optional control signals) |

| Data Transfer and Reporting | Ethernet for remote support via internet, USB for external keyboard/ mouse/ memory stick | Ethernet for remote support via internet, USB for external keyboard/ mouse/ memory stick |

| Other Features | Direct variable conveyor speed by product, Intel Core i, MultiCore CPU, Win OS | Direct variable conveyor speed by product, Intel Core i, MultiCore CPU, Win OS |

| Supplied Test Equipment | Certified test cards with glass, ceramics, steel spheres in various diameter | Certified test cards with glass, ceramics, steel spheres in various diameter |

| Available Accessories | Radiation detector, SHARKNET® data management software, reject bin | Radiation detector, SHARKNET® data management software, reject bin |

| Weight | 0,4 t | 0,5 t |

| Electrical Connection | 220-240 VAC, 1ph, 50 to 60 Hz, 0.3 kW full operation, <0.1 kW stop/idle | 220-240 VAC, 1ph, 50 to 60 Hz, 0.3 kW full operation, <0.1 kW stop/idle |

| Compressed Air Supply | Without reject system 0 (zero)bar With optional reject system minimum 4 bar | Without reject system 0 (zero)bar With optional reject system minimum 4 bar |

| Environmental Conditions | 0 to +30 °C, with relative humidity max 90% non-condensing | 0 to +30 °C, with relative humidity max 90% non-condensing |

| Conformity | CE, compliant to German x-ray regulations, specific adaptation for other countries | CE, compliant to German x-ray regulations, specific adaptation for other countries |

Compatibility Check - Bulk Product X-Ray Inspector Installations

Bulk Flow X-Ray Used in Nut and Almond Processing

Bulk X-ray with XIA Image Processing Software for Dried Fruit and Legume Application

Bulk X-ray with Integrated Reject Flap for Confections and Candy Manufacturing