Ideal for Heavy Product Flows

MPI magnetic tubes are manufactured in the USA and designed to remove small to medium-sized ferrous tramp metal contaminants from various product streams, both dry and liquid. These tubes help protect process equipment and ensure high product quality by eliminating metal debris resulting from wear or contamination. Each tube features durable construction with fully welded ends and 1/4”-20 tapped holes. MPI utilizes Neodymium rare earth magnets, known for their high Maximum Energy Product, with 52 MGOe being the peak for commercial use. To cater to diverse applications, MPI offers a range of magnetic tube models, ensuring customers can find an optimal balance between performance, cost, and durability. An MPI-trained professional is available to assist in selecting the right magnet, emphasizing the importance of expert consultation, especially when installing thin-wall magnets. The introduction of the Hi-G Magnetic Tube provides competitive pull values similar to the strongest non-thin-walled tubes while maintaining durability. For tailored magnetic solutions, customers are encouraged to contact MPI.

Benefits of the Tube Magnet From Magnetic Products, Inc

-

Engineered for Superior Durability & Hygiene

All magnet tube ends are fully welded, providing exceptional durability and a hygienic design. Unlike crimped or mechanically sealed end plugs, welded ends significantly reduce contamination risks and enhance longevity in challenging environments.

-

Designed for Optimal Magnetic Performance

Constructed with a heavy-wall thickness tube to boost durability and strength. Additionally, thin-walled high-performance magnetic tubes are available for improved magnetic efficiency, as outlined in the comparison table below.

-

Flexible Designs for Any Budget & Application

Offered in various configurations to accommodate diverse performance needs and budget considerations. Options range from standard-duty to high-intensity magnetic solutions, ensuring the perfect match for every requirement.

-

Distinctive MPI Materials & Coatings

Specialized non-stick coatings minimize product buildup, enhancing efficiency and simplifying cleaning processes. Abrasion-resistant coatings increase lifespan, making these tubes suitable for handling tough or abrasive materials.

-

Proudly Made in the USA

Designed, engineered, and manufactured in Highland, MI, under rigorous quality control standards. Adherence to industry regulations guarantees reliability and consistent performance.

-

Industry-Leading Turnaround Times

Quick and efficient production allows for some custom sizes and configurations to ship within 24 hours. Short lead times help reduce downtime and maintain seamless operations.

-

Simple Integration & Customization

Magnetic tubes are available in various diameters, lengths, and strengths, ensuring seamless integration into existing systems. Customization options are tailored for optimal performance in specific industrial applications.

-

Dependable and Effective Magnetic Separation

Delivers excellent ferrous metal capture for sectors such as food processing, pharmaceuticals, and manufacturing. This helps enhance product purity, lower equipment wear, and safeguard downstream processes.

Tube Magnet Product Details

MPI magnetic tubes provide an efficient, cost-effective solution for removing ferrous tramp metal contaminants from product streams. These tubes are strategically placed within processing lines to capture, isolate, and retain metal particles, preventing equipment damage and ensuring product purity.

At its core, an MPI magnetic tube is designed to capture and retain unwanted ferrous metal contaminants, protecting your product and process. What sets MPI apart is our commitment to providing the RIGHT solution—balancing strength, durability, and cost for your specific application. Contact an MPI magnet professional today to find the best fit for your production line.

Magnetic Tube Placement & Installation

- MPI magnetic tubes are 1” in diameter and are typically installed within a housing, using tapped end holes (1/4"-20) for secure attachment.

- These tubes can be used individually or in multi-row configurations, depending on the level of protection required.

- The product stream flows around the magnetic tubes, allowing the embedded high-intensity Neodymium magnets to attract and capture ferrous metal contaminants.

Metal Capture & Retention Process

- As material moves through the system, the powerful magnetic field draws in and holds ferrous contaminants, including fine metal particles, metal shavings, and larger tramp metal debris.

- The captured contaminants migrate to the underside of the tube, which prevents "wash-off"—ensuring metals stay securely attached even in high-flow environments.

- This process prevents metal recontamination and ensures efficient separation.

Easy Cleaning & Maintenance

- MPI magnetic tubes are designed for quick removal and easy cleaning to maintain maximum performance.

- Cleaning is performed by simply wiping away the accumulated ferrous material or using a quick-release mechanism in certain configurations.

- This simple cleaning process minimizes downtime while ensuring continuous operation.

Choosing the Right Magnetic Tube for Your Application

At MPI, we understand that a one-size-fits-all approach doesn’t work when it comes to magnetic separation. That’s why we offer multiple tube designs to help balance performance, cost, and durability for your specific needs. Key factors affecting magnetic tube selection include:

- Raw material strength (Neodymium, Samarium Cobalt, or Ceramic)

- Protective coatings (non-stick and abrasion-resistant options)

- Wall thickness (thinner walls enhance pull strength but may reduce durability)

- Pole piece size and magnetic circuit characteristics

MPI’s magnet professionals are available to help customers select the best solution for their unique processing requirements.

The Hi-G Magnetic Tube – Strength & Durability Without Compromise

For applications demanding both high pull strength and long-term durability, MPI has developed the Hi-G Magnetic Tube.

- Unlike standard thin-walled tubes, the Hi-G Tube offers high pull values comparable to the “strongest on the market” non-thin-walled tubes.

- It provides enhanced durability, ensuring longevity in demanding applications without compromising magnetic strength.

- This exclusive MPI technology bridges the gap between performance and durability, giving customers a reliable, long-lasting solution.

Proudly Manufactured in the USA

- MPI magnetic tubes are engineered and manufactured in Highland, MI, under strict quality control guidelines.

- They meet the highest industry standards for durability, sanitary design, and magnetic performance.

Applications & Industries Served

MPI magnetic tubes are widely used across food processing, pharmaceutical, plastics, recycling, and industrial manufacturing industries. Common applications include:

- Removing ferrous contaminants from dry bulk materials such as powders, granules, and pellets.

- Capturing metal fines from liquid or slurry-based products.

- Preventing wear-related metal contamination, caused by metal-on-metal contact within processing equipment.

- Protecting critical downstream machinery, such as mills, grinders, and extruders.

The Science Behind Neodymium Magnets

MPI magnetic tubes utilize high-strength Neodymium Rare Earth Magnets, composed of a mixture of:

- Neodymium (Nd)

- Iron (Fe)

- Boron (B)

- Cobalt (Co)

- Dysprosium (Dy) & Praseodymium (Pr), which enhance temperature resistance

The Maximum Energy Product (MGOe) determines a magnet’s strength. Currently, 52 MGOe is the highest commercial-grade energy product available, ensuring maximum performance in MPI’s magnetic tubes.

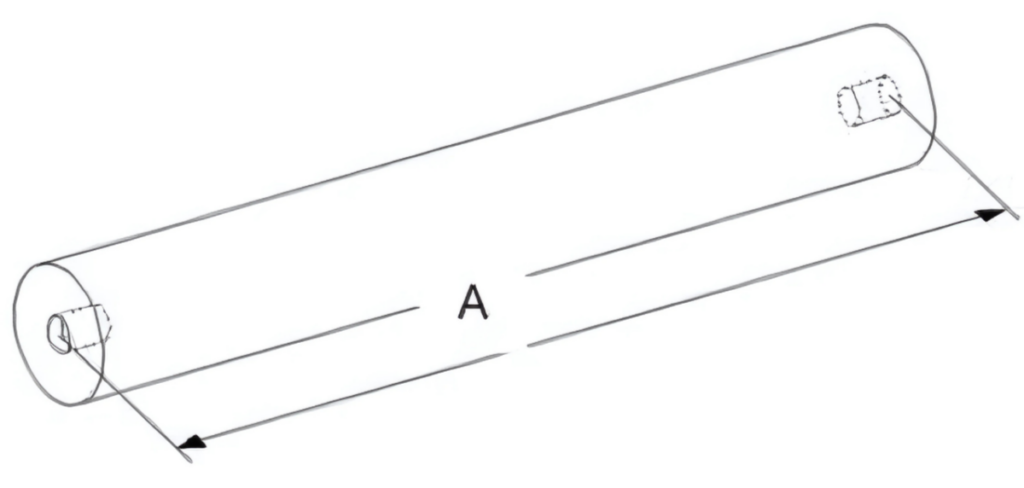

Tube Magnet Specification Table

US Customary Units

| MAGNETIC TUBE MODEL # | (A) TUBE LENGTH (IN.) | APPROX. WEIGHT (LBS.) |

|---|---|---|

| MT-104 | 4 | 0.75 |

| MT-106 | 6 | 1.12 |

| MT-108 | 8 | 1.50 |

| MT-110 | 10 | 1.87 |

| MT-112 | 12 | 2.24 |

| MT-114 | 14 | 2.62 |

| MT-116 | 16 | 2.99 |

| MT-118 | 18 | 3.37 |

| MT-120 | 20 | 3.74 |

| MT-122 | 22 | 4.11 |

| MT-124 | 24 | 4.49 |

Tube Magnet Installations & Variations

1" Magnetic Tube with Tramp Metal Rated for Temperatures of 176°F @ 52-55 MGOe

Magnetic Tubes in Grate Magnet Saturated with Fine Particle Tramp Metal

3" Stainless-Steel Magnetic Tubes with Fine Particle Tramp Metal