MPI Inline Drawer and Plate Magnets are efficient magnetic separators meant for direct installation in pneumatic conveying lines, either horizontally or vertically. They effectively capture and hold ferrous contaminants in free-flowing powders, granules, and dry bulk materials, safeguarding downstream equipment and ensuring product purity. The Inline Drawer Magnets feature high-intensity rare earth magnetic cartridges in a stainless-steel housing for optimal contact with the product stream, while Inline Plate Magnets utilize strong magnetic plates within the duct to remove tramp metal from high-velocity materials. Offered in manual, quick-clean, and self-cleaning versions, these magnets are particularly suited for sectors such as food, plastics, pharmaceuticals, and chemicals, thanks to their compact design and easy access for cleaning, making them compliant with FDA, USDA, and cGMP standards.

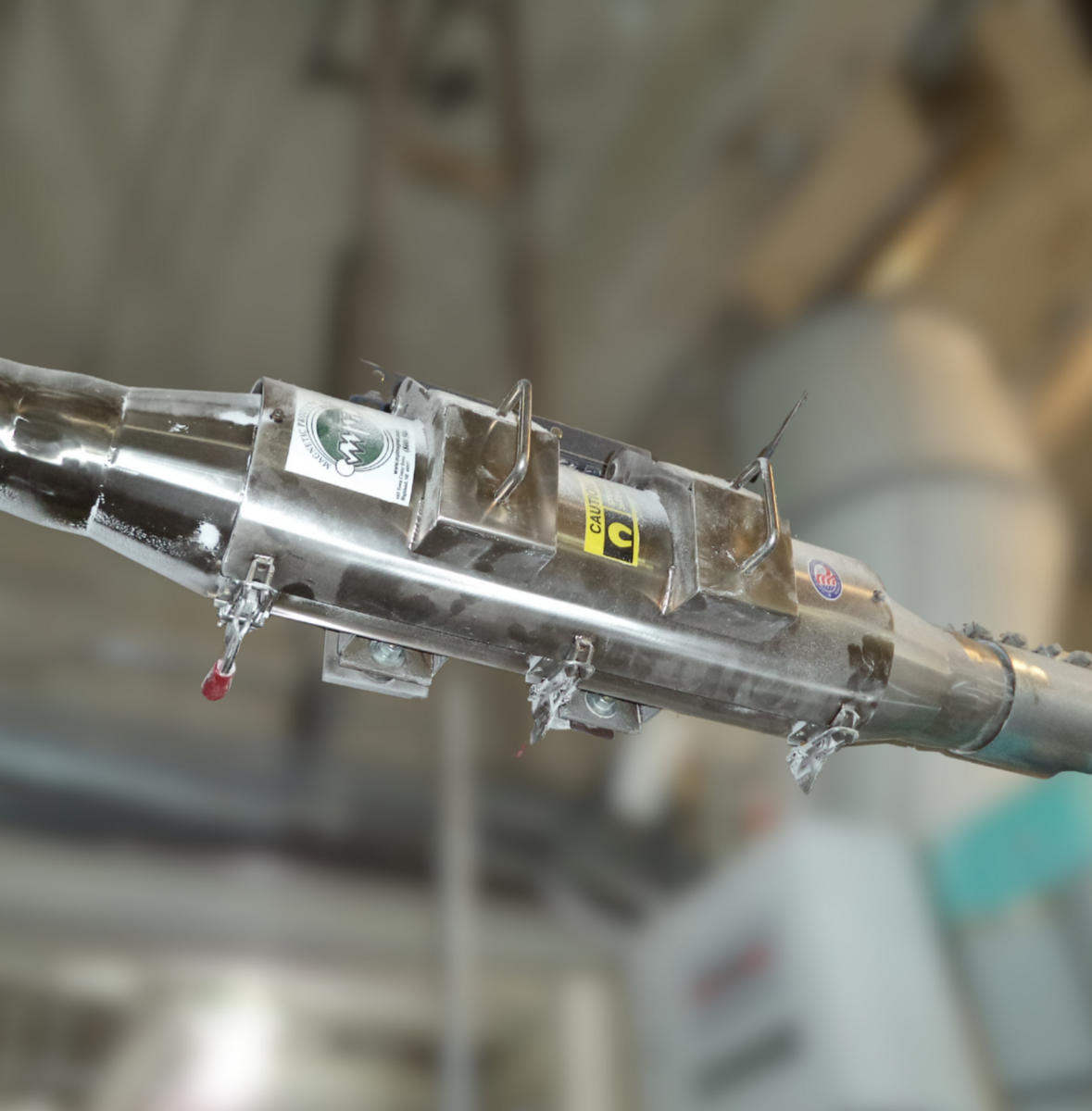

MPI Pneumatic Line Magnets are designed for high-velocity pressure and vacuum conveying systems, enabling inline metal separation without disrupting material flow. These compact, cartridge-style separators are installed in pneumatic pipelines and feature powerful rare earth magnets to capture fine and weakly magnetic contaminants in real time. Constructed from rugged, hygienic stainless steel with tool-less access to the magnetic core, they provide effective protection for sensitive downstream equipment like rotary valves and packaging machinery. Their modular design allows for versatile horizontal and vertical mounting, making them suitable for various conveying layouts. Ideal for the food, plastics, nutraceutical, and powder-based industries, these magnets ensure excellent ferrous separation performance in environments where speed, space, and cleanliness are essential, with options for sanitary finishes and custom fittings for easy integration into regulated processing systems.

Compatibility Check - What Type of Magnetic Separation Fits Your Application

MPI's Inline Drawer and Plate Magnets, as well as Pneumatic Line Magnets, are specialized magnetic separators designed to effectively eliminate ferrous contaminants from dry, free-flowing materials in pneumatic conveying systems. These high-intensity separators are installed directly in pipelines to capture tramp metal, thus ensuring product purity and safeguarding downstream equipment. Available in various configurations, including drawer, plate, and cartridge, they cater to different pipeline diameters and flow rates. Featuring rare-earth magnetic circuits and sanitary stainless-steel construction, options include manual, quick-clean, or self-cleaning designs. Their compact size and tool-free access make them ideal for space-constrained areas, especially in food and pharmaceutical industries. MPI's pneumatic inline magnets can be installed both vertically and horizontally, offering reliable protection in high-velocity processing lines while adhering to FDA, USDA, cGMP, and other regulatory standards.