MPI’s Automated Sorting Systems provide advanced, high-efficiency solutions for material recovery facilities (MRFs), waste management, and industrial recycling operations. Designed to maximize throughput and resource recovery, these systems integrate magnetic, eddy current, and sensor-based technologies to accurately separate ferrous and non-ferrous metals, plastics, paper, and other recyclable materials.

Engineered for automated, high-volume processing, MPI’s sorting systems reduce manual labor, improve material purity, and enhance overall operational efficiency. Whether for single-stream recycling, mining, e-waste recovery, or complex industrial sorting applications, MPI delivers customizable solutions to meet the demands of modern recycling and resource recovery industries.

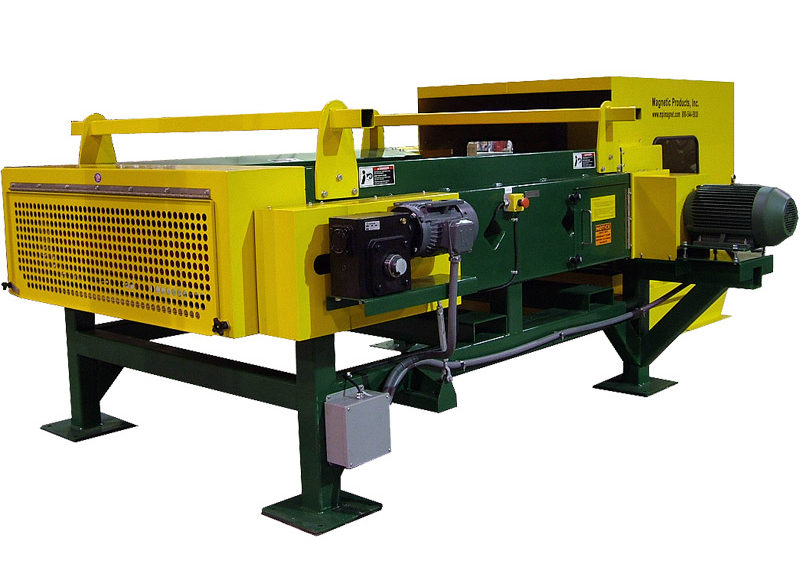

MPI’s Magnetic Drum Separator and Housing provides continuous, automatic removal of tramp iron from heavy, abrasive materials such as coal, aggregates, ores, sugarcane, and wheat. Engineered for high-volume processing environments, this rugged separator features a rotating drum equipped with a powerful permanent magnetic field that captures ferrous contaminants directly from the product stream. The rotating shell then carries the captured metal out of the magnetic field, where it is discharged into a separate collection area, ensuring efficient, maintenance-friendly separation and enhanced equipment protection.

MPI’s Magnetic Head Pulley Separation Roll Magnets effectively remove ferrous tramp iron contaminants from product streams in belt conveyor systems, operating continuously as head pulleys. These SR-series separators attract and retain metal until it exits the magnetic field, enabling the discharge of purified material. Ideal for industries such as recycling, mining, and food processing, where material purity is crucial, these durable magnets also help reduce equipment wear, minimize costly downtime, and enhance the quality of the final product.

Magnetic Belt Feeders are designed for applications where weakly ferrous materials, such as stainless steel or embedded contamination, need to be automatically removed from a product stream. The system uses a high-intensity rare earth magnetic design that increases the gauss on the surface of the belt compared to a magnetic head pulley design, ensuring a stronger and more consistent separation. This enhanced magnetic field effectively captures even the most challenging ferrous contaminants, improving product purity and protecting downstream processing equipment.

MPI's Eddy Current technology improves the separation of nonferrous metals, effectively extracting smaller particles such as aluminum and brass from non-conductive waste. Eddy Current Separators (ECS) are utilized in various sectors, including municipal waste processing, auto shredding, beverage can sorting, glass and foundry sand recovery, and recycling of windows, plastics, and scrap wood. The integration of advanced system controls and technological enhancements greatly increases the efficiency of metal removal.

Commingled Sorting Systems maximize resource recovery by efficiently separating mixed recyclables using magnetic, eddy current, and sensor-based technologies. Ideal for MRFs, waste management, and industrial recycling, they excel in processing heavily commingled materials like tire recycling, municipal solid waste, crushed batteries, and compounds, with a focus on ferrous metal reclamation and contamination reduction.

Detection sorting is a process that separates metals from a product stream by assessing conductivity or ferrous permeability. Utilizing advanced metal detection technology, the system continuously monitors the product. Upon detection of any conductive or ferrous metal, a sensor triggers a reject gate or air blast downstream to automatically eliminate the metal from the stream.

Compatibility Check - Automated Sorting Systems Comparison

Unique Benefits and Considerations

| Sorting Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Drum Separator | Heavy-duty design optimized for bulk ferrous metal removal, with minimal maintenance required. Robust and low-maintenance; effective for bulk ferrous metal separation; handles high material flow. | Limited to ferrous metals; not effective for non-ferrous material separation. |

| Separation Roll | High-intensity magnetic field for capturing fine ferrous contaminants, ideal for precision applications. High-intensity magnetic separation for fine ferrous contaminants; ensures maximum metal recovery. | Higher energy consumption; primarily effective for fine ferrous materials. |

| Magnetic Belt Feeder | Enhances efficiency of magnetic separation by optimizing material feed into downstream systems. Improves magnetic separation efficiency; ideal for feeding materials into other separation systems. | Requires proper material flow control; primarily enhances magnetic separation rather than standalone sorting. |

| Eddy Current Separator | Specialized in non-ferrous metal recovery using eddy currents to repel aluminum, copper, and brass. Efficient recovery of non-ferrous metals; enhances material purity; reduces manual sorting. | Best suited for non-ferrous separation only; requires proper feed control for optimal performance. |

| Commingled Sorting Systems | Versatile system capable of handling highly mixed waste streams, integrating multiple sorting technologies. High-efficiency separation of mixed recyclables; reduces contamination; customizable for various waste streams. | Higher initial investment; requires integration into existing sorting lines. |

| Detection Sorting | Uses advanced optical and sensor-based detection to precisely separate materials by composition. Precise material identification using advanced sensors; ideal for separating all metals from other contaminants. | Sensor-based sorting requires regular calibration; effectiveness depends on material composition. |

Industries, Applications and Regulations

For assistance in selecting the most suitable automated sorting system for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!