Powerful, Oil-Cooled Electromagnet

MPI's Quick-Clean Suspended Electromagnets are engineered to effectively eliminate both large and small tramp metal from product streams transported by vibratory beds or belts at speeds reaching 250 feet per minute. These powerful oil-cooled electromagnets are specifically designed to extract large and medium tramp metal from conveyed products that have significant burden depths.

The Quick-Clean Suspended Electromagnets function as robust oil-cooled electromagnetic plate magnets, positioned above the product streams. It is crucial to place the magnet in a location along the production line that facilitates easy maintenance, ensuring that no integral components of the conveying system, such as idler rollers, pulleys, or belt support plates, become magnetized during operation.

Benefits of the Quick-Clean Suspended Electromagnet From Magnetic Products, Inc

-

Powerful Oil-Cooled Electromagnet

The internal coil is immersed in a dielectric oil bath, allowing the magnet to operate at higher intensities and longer duty cycles without overheating—ideal for demanding, continuous-use environments.

-

Effective Tramp Metal Removal at High Burden Depths

Engineered to remove both large and medium-sized tramp iron from conveyed materials with deep burden layers, this solution maximizes protection for downstream crushers, grinders, and processing equipment.

-

Quick-Clean Design for Faster Maintenance

The manually operated quick-clean configuration enables operators to safely access and remove accumulated metal from the magnet surface with minimal downtime, requiring no tools or disassembly.

-

Designed for Belt and Vibratory Conveyors

Versatile mounting options make the ERBM ideal for use over both belt conveyors and vibratory beds, handling material flow rates up to 250 feet per minute with consistent separation efficiency.

-

Rugged, Industrial-Grade Construction

Built with heavy-duty steel housing and impact-resistant components, the ERBM is well-suited for harsh operating conditions across various industries, including mining, recycling, aggregate, and others.

-

Energy-Efficient Performance

While the unit requires electrical power, the oil-cooled design enhances thermal efficiency and magnetic field strength, reducing energy waste and increasing the lifespan of internal components.

-

Equipment and Product Protection

By removing ferrous contaminants from product streams, the ERBM prevents costly equipment damage, reduces fire and explosion risks, and helps maintain high-quality end products.

-

Field-Adjustable Suspension Height

Suspension Height can be adjusted based on burden depth, material size, and desired separation performance, allowing the system to be fine-tuned for specific applications and installations.

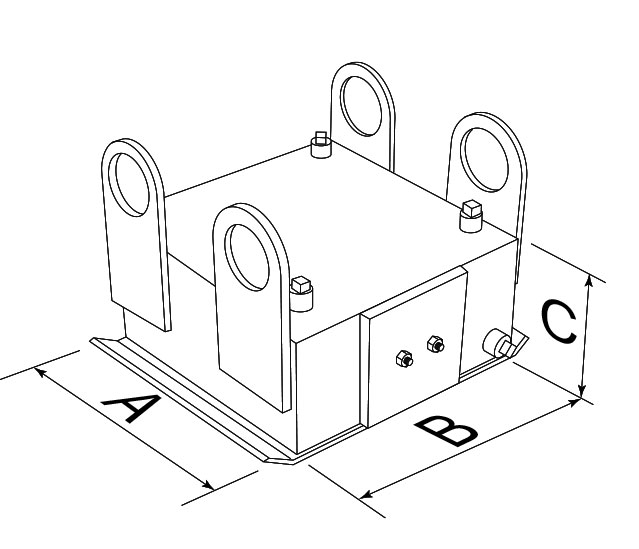

US Customary Units

| MODEL # | (A) MAGNET WIDTH (IN.) | (B) MAGNET LEGNTH(IN.) | (C) MAGNET HEIGHT (IN.) | VOLTAGE | WATTAGE | UNIT WEIGHT (LBS.) |

|---|---|---|---|---|---|---|

| ERBM-18 | 18 | 18 | 9 | 115 VDC | 900 | 750 |

| ERBM-24 | 24 | 24 | 12 | 115 VDC | 1600 | 1000 |

| ERBM-30 | 30 | 30 | 15 | 115 VDC | 2500 | 1750 |

| ERBM-36 | 36 | 36 | 18 | 115 VDC | 3600 | 2500 |

| ERBM-42 | 42 | 42 | 21 | 230 VDC | 4900 | 3750 |

| ERBM-48 | 48 | 48 | 24 | 230 VDC | 6400 | 5250 |

| ERBM-54 | 54 | 54 | 27 | 230 VDC | 8100 | 7000 |

| ERBM-60 | 60 | 60 | 30 | 230 VDC | 10000 | 9000 |

Quick-Clean Suspended Electromagnet Installations & Variations

Quick-Clean Suspended Electromagnet for Wood Chip and Mulch Processing

Quick-Clean Suspended Electromagnet for Sand and Gravel Application

Quick-Clean Suspended Electromagnet for Processing Recycled Plastic Streams