Continuous Tramp Metal Removal for High-Speed Conveying

MPI’s Self-Clean Suspended Electromagnet is a robust, high-performance magnetic separation system engineered to automatically remove large and medium tramp iron from heavy burden depths of material on fast-moving conveyor belts. Featuring a durable oil-cooled electromagnet and a motorized self-cleaning belt system, this unit provides continuous, automated removal of ferrous contaminants, ensuring maximum protection for downstream processing equipment and reducing costly unplanned downtime.

Ideal for rugged industrial environments such as mining, aggregates, and recycling, the system is designed for conveyed speeds up to 250 feet per minute and excels in applications where consistent, hand-free operation is critical. The self-cleaning design eliminates the need for manual cleaning cycles, resulting in labor savings, increased throughput, and safer operation.

Benefits of the Self-Clean Suspended Electromagnet From Magnetic Products, Inc

-

Oil-Cooled Electromagnet for Maximum Strength

A sealed, oil-cooled coil ensures high magnetic field intensity and sustained performance during continuous operation—even in the most demanding industrial environments.

-

Self-Cleaning Belt System for Continuous Operation

The motorized belt automatically removes collected tramp metal, eliminating downtime associated with manual cleaning and ensuring uninterrupted system performance.

-

Designed for Fast Conveyor Systems

Optimized for product flow speeds of up to 250 feet per minute, this solution is ideal for high-throughput applications in mining, recycling, and aggregate processing.

-

Handles Large Burden Depths with Ease

Capable of penetrating deep into product layers, allowing for the reliable removal of medium to large ferrous contaminants across a wide range of material types and sizes.

-

Reduces Downtime and Labor Costs

Automated operation significantly reduces manual labor and production interruptions, lowering the total cost of ownership.

-

Protects Downstream Equipment from Damage

Prevents ferrous objects from reaching crushers, grinders, or sensitive processing equipment, reducing repair costs and production losses.

Heavy-Duty Construction for Harsh Environments

Engineered with rugged components to withstand vibration, dust, and demanding outdoor or industrial environments.

-

Flexible Installation Options

Can be customized or adjusted to fit various conveyor widths, product loads, and application-specific separation needs.

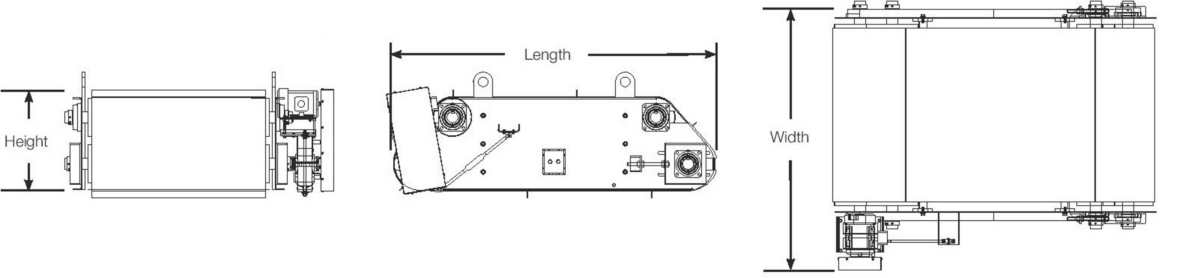

Self-Clean Suspended Electromagnet Product Details

Magnet Suspension & Positioning

The unit is suspended above a conveyor belt, typically perpendicular to the flow of product. Positioned at a strategic height, it creates a magnetic field that penetrates through the burden depth of conveyed material.

Tramp Metal Detection & Capture

As ferrous contaminants (such as bolts, tools, and scrap metal) pass beneath the magnet, they are drawn upward and held against the magnet face due to the powerful oil-cooled electromagnetic field.

Automatic Discharge via Self-Cleaning Belt

A heavy-duty, motor-driven belt travels continuously across the magnet’s surface, sweeping tramp metal away from the magnetic field to a discharge area—typically off the side of the conveyor. This automation eliminates the need to shut down the system for cleaning.

Continuous Protection

The system runs non-stop, ensuring that tramp metal is consistently removed from the process stream, protecting crushers, grinders, screens, and other sensitive equipment from costly damage.

Self-Clean Suspended Electromagnet Specification Table

US Customary Units

| MODEL # | LENGTH (IN.) | WIDTH (IN.) | HEIGHT (IN.) | BELT WIDTH (IN.) | WEIGHT (LBS.) | VOLTAGE | WATTAGE | MOTOR HP |

|---|---|---|---|---|---|---|---|---|

| ECBS-24 | 82 | 53 | 22 | 36 | 1700 | 115 | 1300 | 3 |

| ECBS-30 | 88 | 59 | 29 | 42 | 2800 | 115 | 4061 | 3 |

| ECBS-36 | 84 | 65 | 29 | 48 | 3800 | 115 | 5150 | 3 |

| ECBS-42 | 100 | 71 | 33 | 54 | 5100 | 115 | 6844 | 3 |

| ECBS-48 | 112 | 83 | 34 | 60 | 7000 | 115 | 7885 | 3 |

| ECBS-54 | 112 | 83 | 34 | 66 | 9300 | 115 | 9975 | 5 |

| ECBS-60 | 118 | 89 | 38 | 72 | 12500 | 230 | 14436 | 5 |

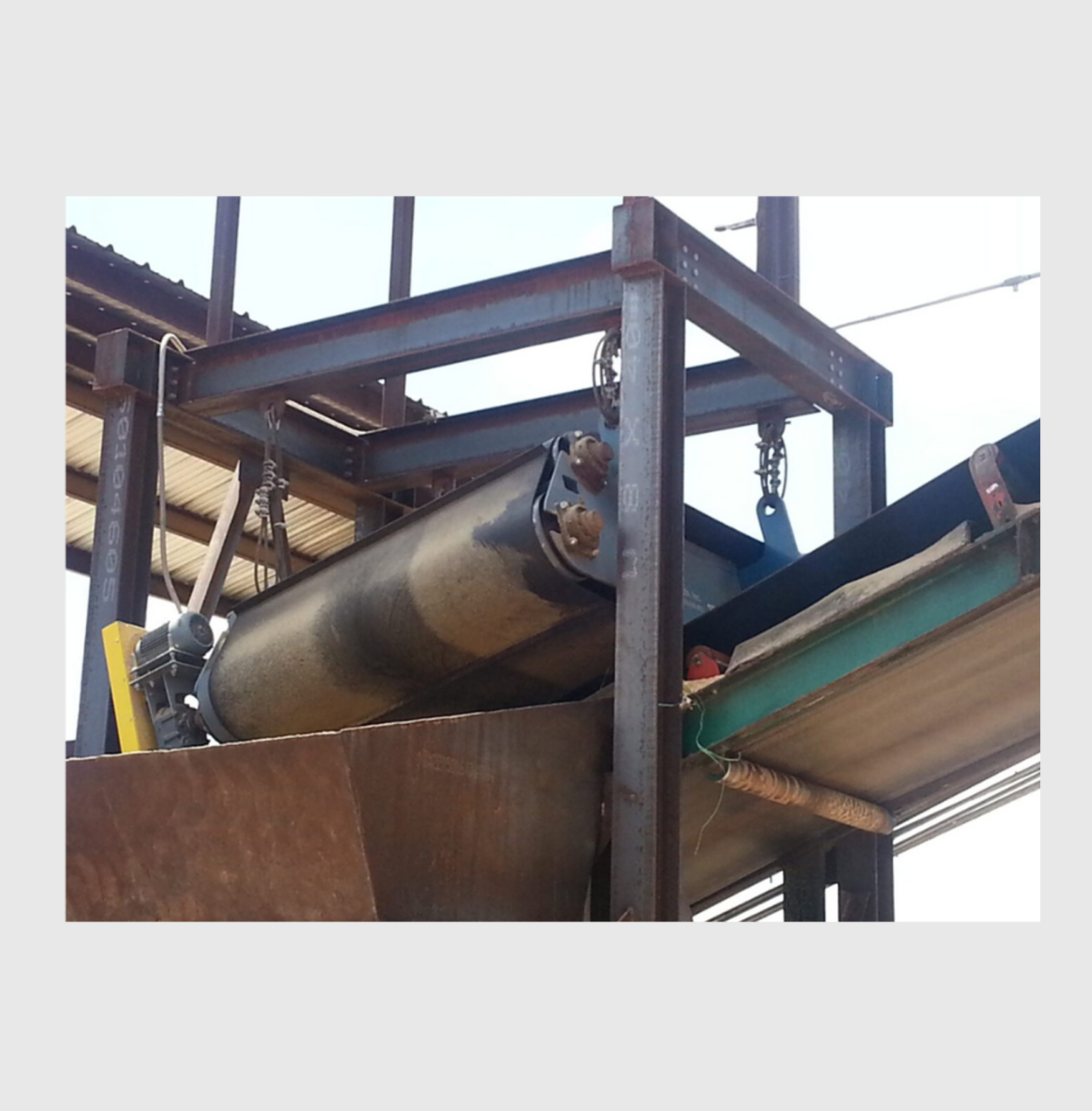

Self-Clean Suspended Electromagnet Installations & Variations

Self-Clean Suspended Electromagnet Installed at Quary for Coal, Taconite, and Limestone

Self-Clean Suspended Electromagnet Specified for Concrete Production, Removing Rebar, Tools, and Scrap Metal

Self-Clean Suspended Electromagnet Installed at a Steel Foundry to Prevent Contamination and Damage to Furnaces and Casting Lines