Easy Integration into Belted Conveyor Systems

MPI’s Magnetic Pulleys transform standard conveyor head or tail pulleys into automatic tramp metal separation points. Replacing conventional pulleys at the discharge end of a belt conveyor, they attract and hold ferrous debris or loose metal fragments within bulk materials. As the belt turns, clean material discharges normally while metal clings to the pulley surface and is carried under the belt, dropping off below into a collection bin. Ruggedly built for continuous operation in aggregate, recycling, bulk solids, and scrap handling, MPI Magnetic Pulleys protect downstream crushers, grinders, or process lines from metal damage while recovering valuable ferrous material.

Benefits of the Workholding Pulleys From Magnetic Products, Inc

-

Continuous Metal Removal

Automatically separates tramp metal without interrupting flow.

-

Simple Retrofit

It replaces any standard conveyor pulley; there is no complex installation.

-

Protects Downstream Equipment

Prevents costly damage to crushers, grinders, or mixers.

-

Cost-Effective Recovery

Recovers valuable scrap metal for recycling revenue.

-

Low Maintenance

No moving parts beyond the conveyor belt; sealed magnet core.

-

Heavy-Duty Construction

Withstands harsh environments and abrasive bulk materials.

-

Versatile Applications

Suitable for aggregates, mining, recycling, and bulk solids.

-

Energy-Free Operation

Permanent magnet core requires no power.

Workholding Pulleys Product Details

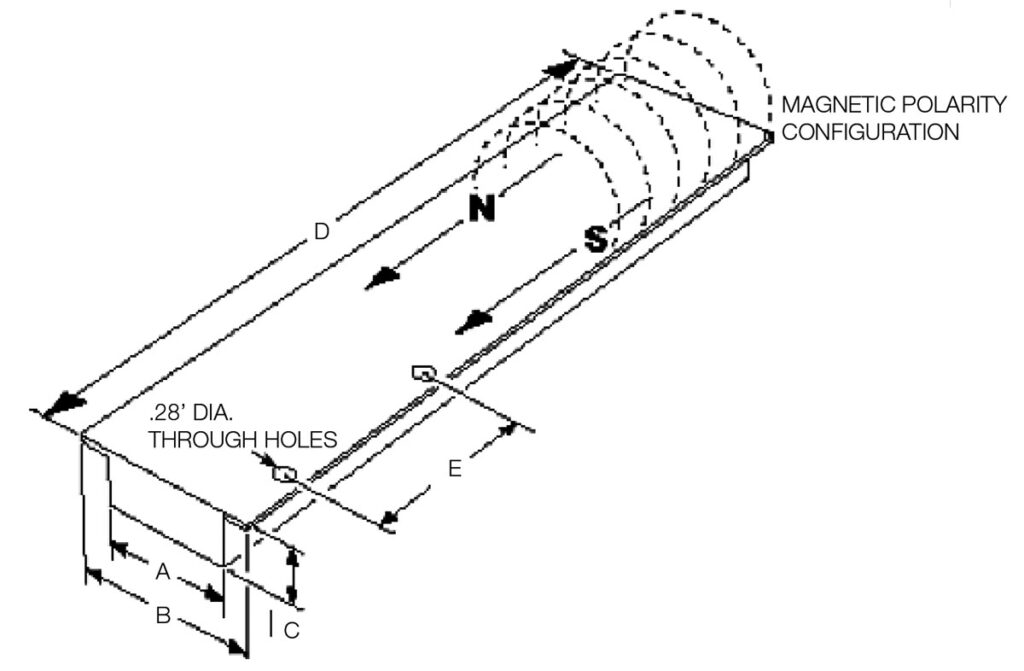

Magnetic Box Rails and T-type box Rails are usually mounted in tandem with magnetic pulleys and other rails beneath a conveyor’s belt. The standard design provides quick installation to a conveyor’s framework or table and can be custom-designed and manufactured to your specifications.

Pulleys are typically used as transfer devices in belt conveyors. As metal nears the pulley’s magnetic field, it is attracted and held to the conveyor’s belt until it reaches the transfer point.

- Install: Replace your conveyor’s head (or tail) pulley with MPI’s Magnetic Pulley.

- Convey: Bulk material travels on the belt to the discharge end.

- Attract: As material reaches the pulley, embedded magnets attract and hold ferrous pieces to the pulley’s surface.

- Separate: Non-ferrous or clean material follows its typical discharge trajectory.

- Carry: The belt’s rotation carries the captured metal underneath the pulley.

- Discharge: Metal loses contact with the magnetic field past the bottom, dropping into a separate chute or bin.

Workholding Pulleys Specification Table

US Customary Units. WIDTH (B): Built to customer’s specifications (1″ flange, standard). LENGTH (D): Built to customer specifications (up to 8″). TAP DISTANCE (E): Built to customer specifications (12″ on-center in backplate standard).

| RAIL AND PULLEY MODEL # | (A) INNER WIDTH (IN.) | (C) THICKNESS (IN.) |

|---|---|---|

| BR-2 | 2.63″ | 0.56″ |

| BR-4 | 4.19″ | 0.81″ |

| BR-6 | 4.19" | 1.06" |

| BR-8 | 4.19" | 1.31" |

| BR-12 | 4.19" | 1.94" |

| BR-16 | 5.19" | 2.56" |

| BR-24 | 8.19" | 4.06" |

| BRT-2 | 2.63" | 0.56" |

| BRT-4 | 4.19" | 0.81" |

| BRT-6 | 4.19" | 1.06" |

| BRT-8 | 4.19" | 1.31" |

| BRT-12 | 4.19" | 1.94" |

| BRT-16 | 5.19" | 2.56" |

| BRT-24 | 8.19" | 4.06" |

Workholding Pulleys Installations & Variations

MPI Magnetic Pulleys for Automatic Separation of Tramp Metal Without Interrupting Flow

MPI Magnetic Pulleys for Tire Shredding and Recycling Application

MPI Magnetic Pulleys for Canning Application