Compact, Reliable Scrap Removal for Press and Metal Forming Applications

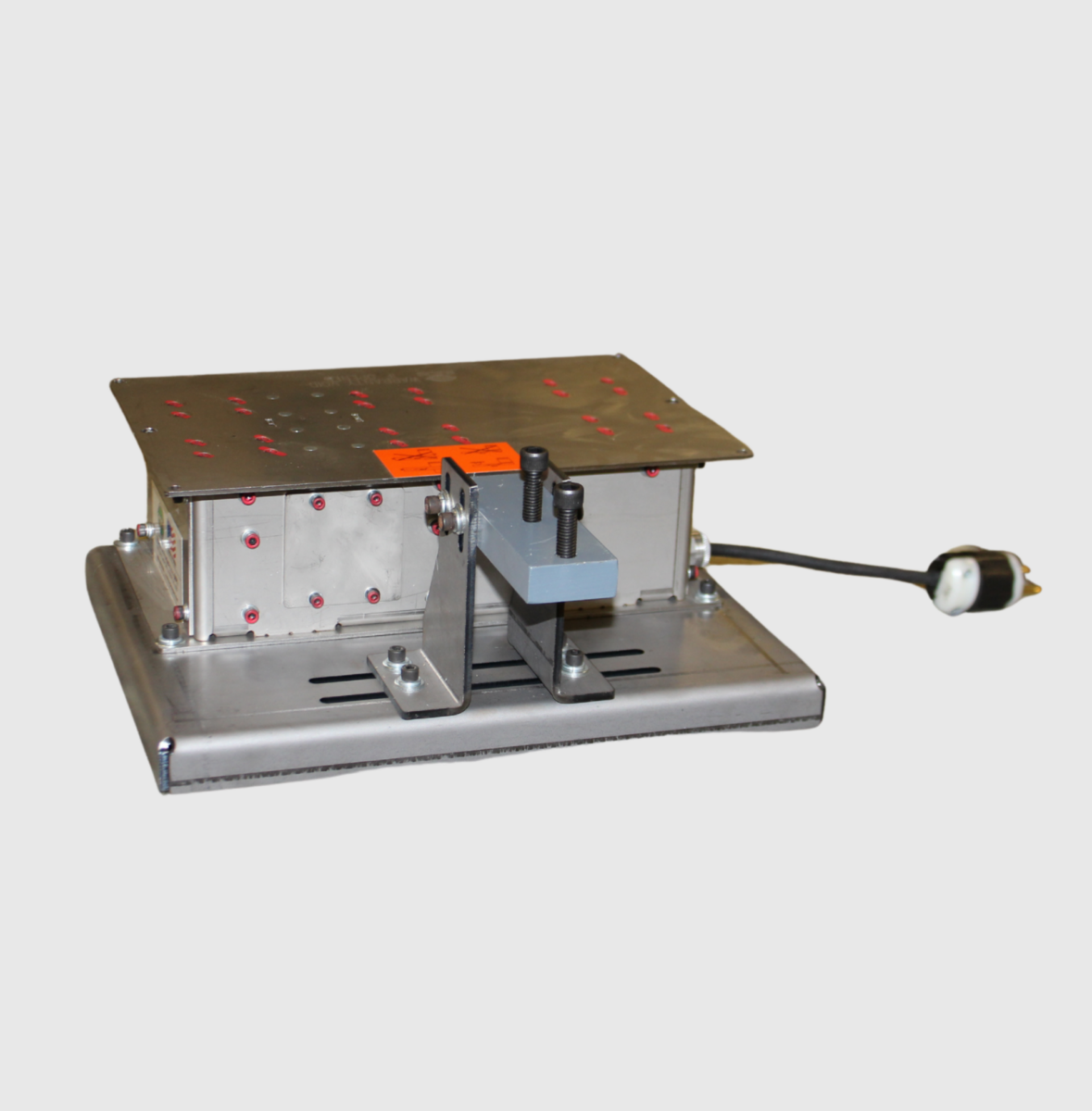

The MPI M-10 Electric Scrap Shaker is a compact, low-maintenance conveyor system engineered to move stamping and trimming scrap from under presses or forming stations with smooth, quiet, and efficient motion. Designed for light-to-moderate-duty applications, the M-10 replaces noisy and failure-prone belt or pneumatic conveyors with an electromechanical drive system that delivers consistent linear motion without complex mechanics or excessive wear parts.

The M-10 Electric Scrap Shaker uses a direct-drive electric motor to generate horizontal oscillations that move scrap material along bolted-on troughs. It is ideal for space-constrained work cells, robotic automation environments, and stamping operations seeking dependable scrap handling without hydraulic leaks, belts, or compressed air.

Engineered for 24/7 reliability and minimal operator involvement, the M-10 Electric Scrap Shaker can be easily integrated into new or existing press lines and supports multiple trough configurations for flexible layout planning.

Benefits of the M-10 Electric Scrap Shaker From Magnetic Products, Inc

-

Electric Drive – No Compressed Air or Hydraulics

Powered by a durable, sealed electric motor—no need for shop air, hydraulic lines, or maintenance-heavy pneumatic actuators. Reduces energy costs and system complexity.

-

Smooth, Quiet Linear Motion

Produces a consistent oscillating movement with minimal noise and vibration, creating a safer, more comfortable work environment than traditional scrap-handling solutions.

-

Compact, Low-Profile Design

It fits easily under presses or in tight areas with minimal vertical clearance. It is ideal for cell-based manufacturing and robotic workstations where space efficiency matters.

-

Reliable, Maintenance-Light Operation

Few moving parts and a direct-drive system mean less wear, fewer breakdowns, and reduced downtime, and there are no belts, bearings, or springs to replace frequently.

-

Flexible Trough Configuration

Compatible with single or multiple bolted-on troughs in various sizes and shapes, this system allows for scrap discharge from multiple stations to a centralized collection point.

-

Easy Integration into Existing Lines

Mounts directly to the floor, table, or machine base. Compact electrical controls and standardized voltages make integration with automation systems straightforward.

-

Robust, Industrial Construction

Built for durability in industrial environments with a heavy-duty welded steel frame and sealed electrical components. Suitable for oily, dusty, or dirty conditions common in stamping and trimming operations.

-

Safe and Operator-Friendly

No exposed pinch points or rotating components. Offers improved operator safety and eliminates tripping hazards from belt systems or tangled air hoses.

M-10 Electric Scrap Shaker Product Details

The MPI M-10 Electric Scrap Shaker uses a linear oscillating motion to move stamping scrap, offcuts, or small parts along attached troughs and into designated collection bins or scrap hoppers.

Drive System Activation

The system is powered by an electric direct-drive motor connected to an internal eccentric drive mechanism. When activated, it produces rapid linear reciprocating motion (a forward and backward horizontal “shake”).

Oscillating Motion Transfers Scrap

The motion is transferred to the bolted-on scrap troughs, which are mounted directly to the shaker’s drive base. As the trough vibrates:

- Inertia moves the scrap forward during each cycle

- The backward stroke resets the tray position without pulling the material back

- This creates a steady, stepwise motion toward the discharge point

Scrap Discharge

Scrap material is conveyed along the trough until it reaches the end, where it falls into a hopper, container, or conveyor system for disposal or recycling.

Continuous or Intermittent Operation

The M-10 can run continuously or be triggered by a PLC, sensor, or press control system to operate only when scrap is present, maximizing energy efficiency.

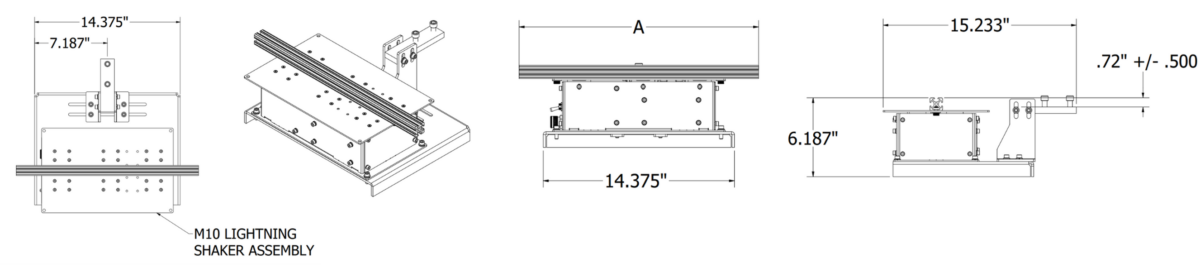

M-10 Electric Scrap Shaker Specification Table

US Customary Units

| MODEL FEATURE | M-10 Motor Only | M-10 System |

|---|---|---|

| Power Input | 110 VAC, single phase | 110 VAC, single phase |

| System Weight | 24 lbs. | 28 lbs. |

| Design Capacity (Pans and Scrap) | 10 lbs. | 10 lbs. |

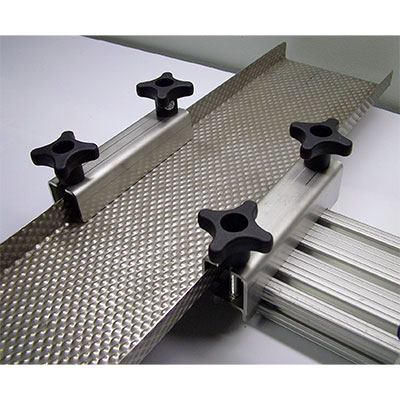

| Crossbar Width Included | Not Included | 18 in. |

| T-Slot Sizes Included | Not Included | 0.50″ Thick x 1.375″ Wide and 3/4″ Thick x 1.75″ Wide |

| Quick Release Pan Mount Bracket Accessory | Not Included | Not Included |

M-10 Electric Scrap Shaker Installations & Variations

MPI M-10 Electric Scrap Shaker for Compact Robotic Workstation

M-10 Electric Scrap Shaker in Shop Without Air, Hydraulic Lines, and Pneumatic Actuators

MPI M-10 Electric Scrap Shaker Mounted for Scrap Discharge from Multiple Stations