Cleaner Floors, Safer Workflows, and Higher Profitabilit

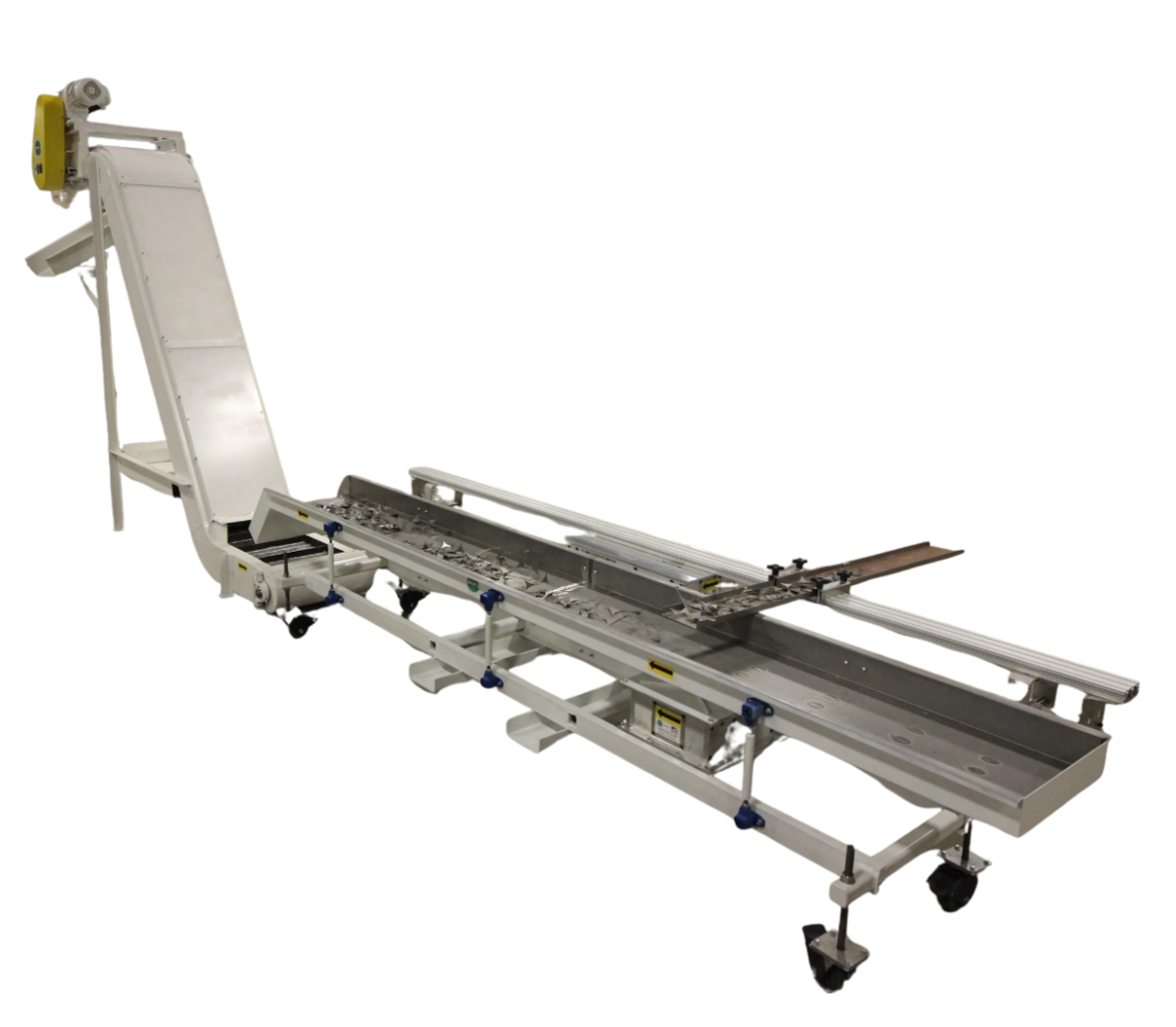

MPI’s Turnkey Scrap Conveying Systems are fully integrated material handling solutions designed to automate ferrous and non-ferrous scrap collection, transport, and discharge in stamping, machining, and fabrication environments. Built around MPI’s magnetic and mechanical conveying technologies, these systems are engineered to fit your plant layout, production rates, and scrap characteristics. Every component is coordinated to deliver safe, clean, and continuous scrap management from in- or above-floor conveyors to lift magnets, hoppers, and discharge chutes. MPI’s turnkey approach minimizes downtime, maximizes scrap value, and eliminates manual handling for safer, leaner operations.

Efficient scrap metal removal and parts handling equipment are essential for any metal forming operation. When executed properly, the supporting equipment for scrap and parts handling enhances the performance of metal forming machinery, allowing it to function at peak efficiency with minimal downtime. MPI's turnkey systems take a comprehensive approach to the entire parts and scrap handling process, designing complete solutions that maximize the return on investment for metal forming equipment. These turnkey systems are adaptable to both single and multiple machine layouts. Whether individual presses, lasers, machining centers, or extensive systems with multiple metal forming tools, MPI can design, build, control, and support the installation of a comprehensive solution tailored for manufacturers.

Benefits of the Turnkey Scrap Conveying Systems From Magnetic Products, Inc

-

Fully Integrated, Ready-to-Run Systems

Custom-engineered for your process flow, scrap volume, and facility layout — no integration guesswork.

-

Modular and Scalable Designs

Adaptable to both small single-press operations and large multi-line plants.

-

Magnetic & Mechanical Conveying Options

Supports beltless magnetic, hinged steel belt, or vibratory conveyors, depending on scrap type.

-

Automated Scrap Removal

Reduces labor, eliminates forklift scrap collection, and keeps press pits and floors clean.

-

Built for Harsh Environments

Heavy-duty frames and wear-resistant components handle hot, oily, or abrasive scrap.

-

Improved Safety & Ergonomics

Minimizes manual lifting and handling, reducing operator injury risk.

-

Optimized for Efficiency

Moves scrap directly to bins, hoppers, or compactors — streamlining plant operations.

-

Service & Support Included

MPI provides project planning, installation, controls integration, and post-install support.

Turnkey Scrap Conveying Systems Product Details

Assessment & Design

MPI engineers assess your scrap generation points, volumes, material types, and plant layout.

System Build

A tailored solution is created, combining conveyors (beltless magnetic, hinged steel belt, vibratory), chutes, sensors, and optional lift magnets.

Installation

Conveyors are installed to collect scrap from under press pits, machining centers, or work cells and transport it to centralized discharge points.

Scrap Collection

As material is generated, it automatically drops onto the conveyor system via integrated hoppers or chutes.

Magnetic or Mechanical Transport

Depending on the configuration, the scrap is moved via magnetic force (beltless) or physically conveyed (belted or vibratory) toward the discharge.

Scrap Discharge

Material is directed into hoppers, bins, or compactors for recycling or disposal.

Continuous Operation

The system operates in sync with production lines, removing non-stop scrap without interrupting workflow.

Ideal For

-

Stamping press lines

-

CNC machining centers

-

Metal fabrication plants

-

Automotive Tier 1 & Tier 2 suppliers

-

Appliance and electronics manufacturers

-

Any facility generating high volumes of ferrous or non-ferrous scrap

Turnkey Scrap Conveying Systems Installations & Variations

MPI Heavy-Duty Turnkey Shaker Conveyor for Tier 1 Automotive Supplier

MPI Heavy-Duty Turnkey Shaker Conveyor Installed at Metal Fabricator

Easy Install and Operation Shaker Conveyor for Ferrous and Non-Ferrous Parts Processing