When a manufacturer claims that they have the “strongest magnet tube on the market” what exactly are they saying? It boils down to their magnet having the highest holding force or highest Gauss level at the surface of the magnet. While this can be a useful measurement, this may not mean that magnet is the right solution for your application.

Regular inspections, cleaning, and maintenance of MPI magnetic separators are essential. This includes, but is not limited to the removal of the collected metal and checking fasteners and seals or other components to ensure they are in proper working condition. See answers to frequently asked questions related to separator maintenance.

In practical application, many magnets lose strength - or degrade - at a much faster rate than would happen naturally. If undetected, this leaves users open to potential metal events, damage to brand reputation, recalls, and other costly consequences. Accelerated strength loss can be caused by a number of environmental factors.

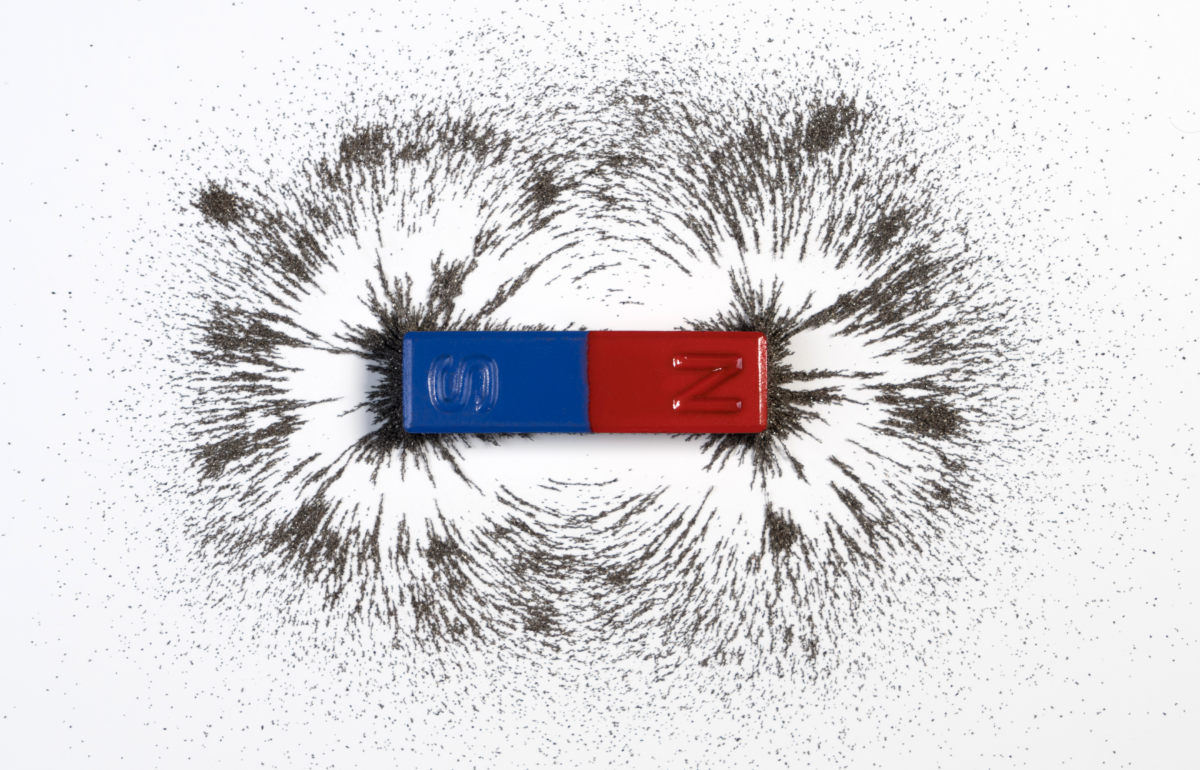

Because magnetic fields are transparent to the human eye, measuring their strength requires specialized tools that measure the working air gap of the magnetic circuit. There are currently two methods for testing a magnetic separator - Gauss Testing and Pull Testing - learn about both tests and instructional testing videos.

MPI’s engineered magnetic separation and metal sorting solutions safeguard your manufacturing process from raw material to finished product. Follow this roadmap showing where to place MPI solutions, which products to choose, and why they matter at each stage of your production flow.

Magnetic separation is a process whereby magnetically susceptible material is extracted from a mixture. Magnetic separators are useful in high volume process flows. They are placed inline so as not to introduce any foreign contaminants from external sources into your production facility.

The most common magnetic material in use today are Ceramic, Alnico, Samarium Cobalt, and Neodymium. Each is made up of different elements used for different applications. See pros and cons of the most common types.

Many customers inquire about magnetism, how to measure it, ways magnets are engineered to attract and retain metal and the types of magnetic circuitry. Find a list of the frequently asked questions compiled by MPI's magnet experts.

Drawer magnets are the most common method to capture fine ferrous tramp metal in medium flows. MPI drawer magnets improve product purity and protect processing equipment. Drawer magnets handle a wide range of separation tasks in mechanical or gravity flow applications

Metal sorting is a process where both large and small ferrous tramp metal is removed from processing lines - often in scrap handling, recycling, or mining applications, but can also be applicable for highly abrasive materials like sugarcane and wheat.