Sensor Enabled Magnetic Separation Monitoring

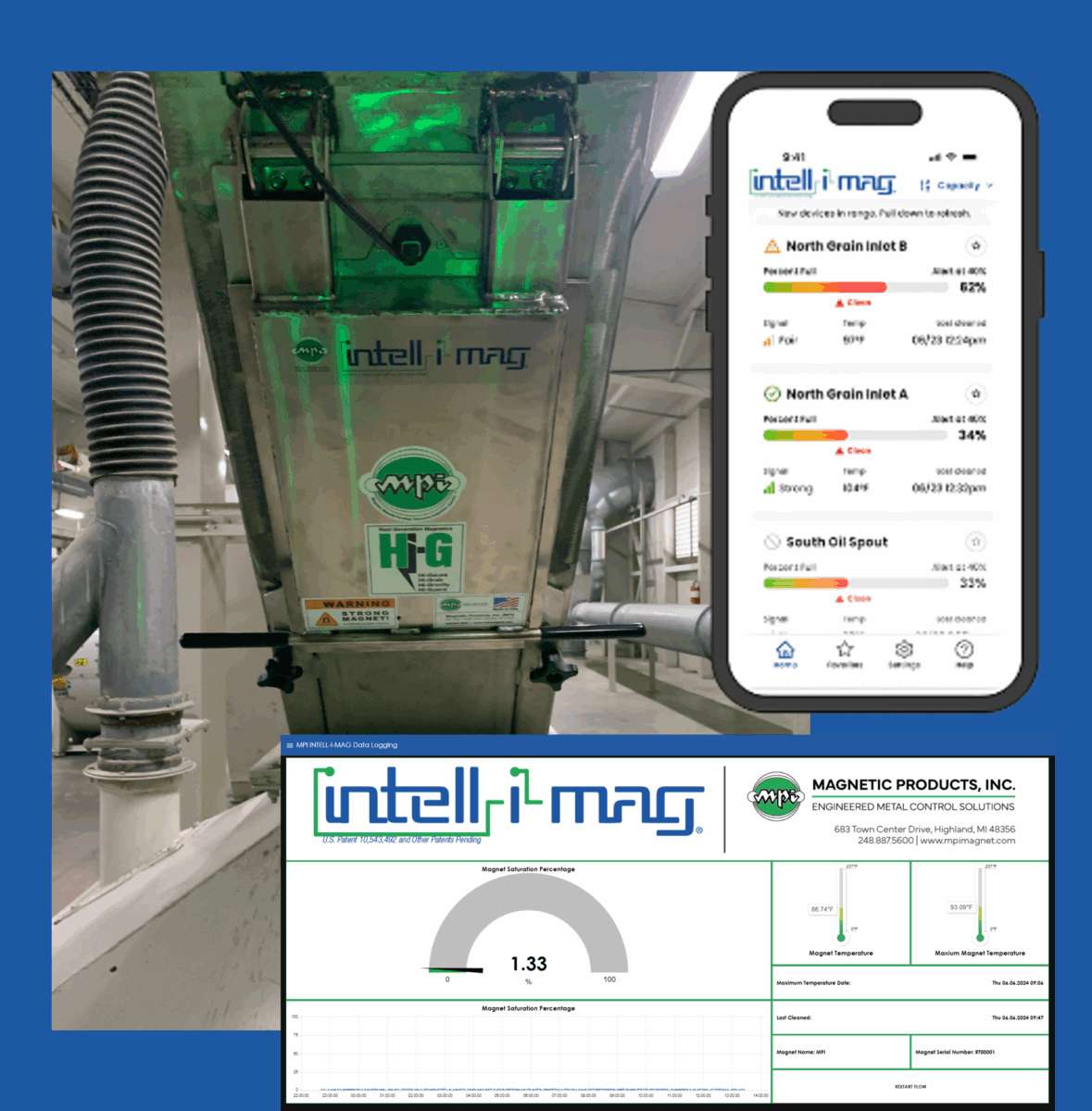

MPI’s patented Intell-I-Mag® is an advanced, sensor-enabled magnetic separator monitor that revolutionizes how industries track, manage, and validate magnetic separation performance. Engineered for critical control points in food, pharmaceutical, plastic, and powder processing environments, Intell-I-Mag® combines real-time magnetic load detection with integrated digital dashboards for unprecedented process visibility. Operators can monitor saturation levels, log cleaning cycles, and ensure regulatory compliance from a mobile device, local display, or remote dashboard. Whether you're managing a single separator or an entire facility of magnetic protection points, Intell-I-Mag® provides the actionable insight and automation needed to streamline operations and protect product integrity.

Benefits of the Intell-I-Mag® From Magnetic Products, Inc

-

Real-Time Magnetic Load Monitoring

Displays magnet saturation percentage, helping schedule cleaning only when needed—maximizing efficiency and minimizing downtime.

-

Mobile App Paired with Web Dashboard Integration

Monitor separators locally via Bluetooth or across your facility’s Ethernet network from any web browser.

-

Customizable Alerts & Thresholds

Set warning levels (e.g., 25% yellow, 50% red) for proactive cleaning and maintenance.

-

Regulatory Compliance & Audit Readiness

Automatically logs performance data and cleaning history to support FSMA, HACCP, GFSI, and 21 CFR Part 11 documentation.

-

Flexible Installation & Configuration

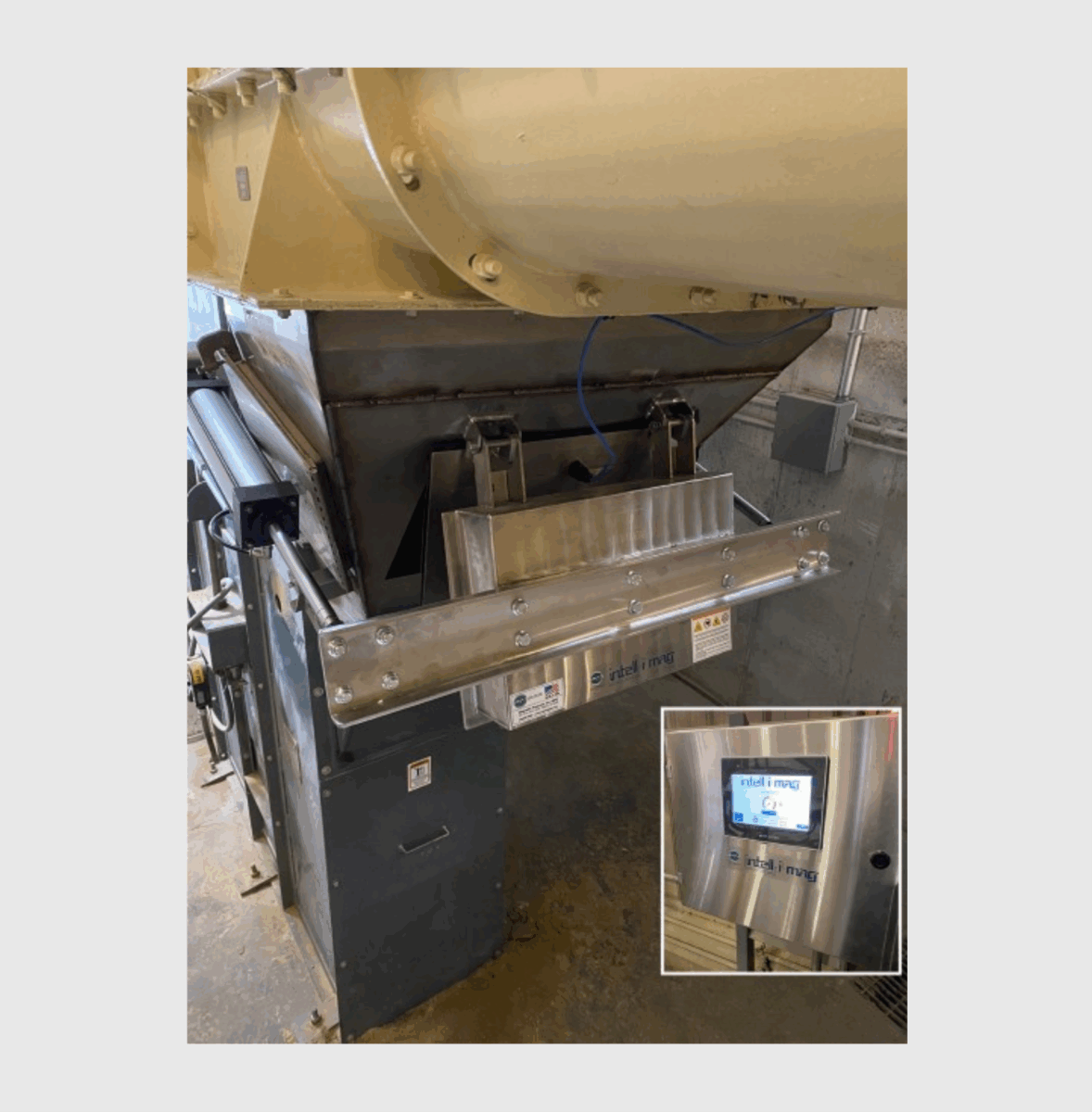

Configure via local interface, HDMI-connected touchscreen, or mobile app. Works with MPI’s most common magnetic separators.

-

PLC Integration for Automation

Enables full communication with facility control systems via IP assignment and Ethernet/IP protocols for Allen Bradley and other PLCs.

-

User-Centric Design

Through a simple user interface, you can name magnets (e.g., “Unload Pit 1”), review temperature history, and manage each unit’s status.

-

Multi-Device Monitoring

Track multiple separators across facilities and view trends through MPI’s centralized dashboard tools.

Intell-I-Mag® Product Details

-

Install the Intell-I-Mag® sensor and controller onto the supported magnetic separator (drawer, chute, inline, etc.).

-

Power on the unit and launch the Intell-I-Mag® mobile app (available for iOS and Android) or connect a touchscreen via HDMI for local display.

-

App scans for nearby devices via Bluetooth. Select the separator, assign a name, set alert thresholds, and configure IP/PLC settings.

-

Begin Monitoring: The dashboard displays saturation percentage, temperature readings, and historical trends.

-

Cleaning alerts are triggered when thresholds are reached. After cleaning, reset or recalibrate as needed.

-

Data is logged automatically for every cleaning event, temperature change, and performance threshold and is available for export and audit.

-

If connected via Ethernet, dashboards can be accessed remotely from any browser or exported for QA analysis.

Intell-I-Mag® Installations & Variations

Intell-I-Mag® Plate Magnet Installed in Food Processing Plant

Intell-I-Mag® Installed in Pet Food Processing

Self-Clean Intell-I-Mag® Installed for High-Volume Production Application