Conveyance Solutions for the Metal Stamping and Fabrication Industries

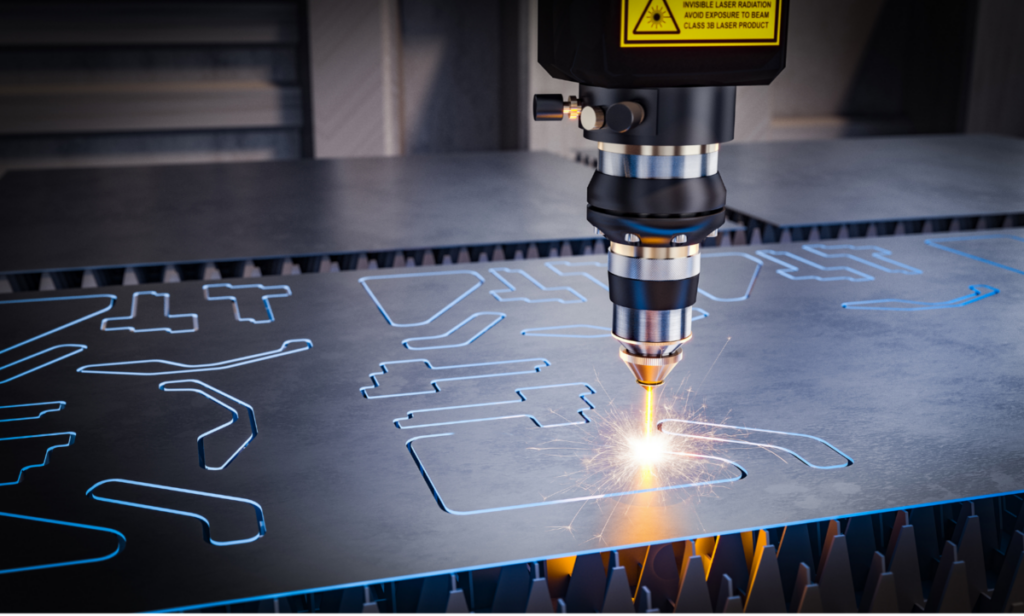

MPI’s magnetic products and scrap handling systems are essential for improving process efficiency, part quality, and plant safety in the metal stamping and fabrication sector. Stamping operations generate significant amounts of ferrous scrap, slugs, and tramp metal, while fabrication involves handling steel sheets, small parts, and shavings.

MPI solutions are used to:

-

Remove and manage scrap metal generated during die cutting and punching.

-

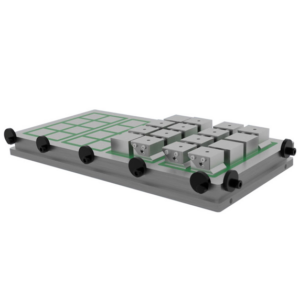

Separate stacked or oily sheet metal blanks for reliable feeding.

-

Transfer parts and scrap with magnetic conveyors and chutes.

-

Protect tools, dies, and downstream equipment from jams or metal debris.

-

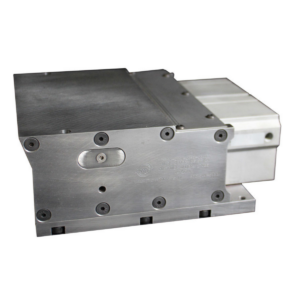

Securely hold metal workpieces during welding, machining, or assembly.

Where they are used:

-

Under presses and punch stations.

-

In robotic destacker systems and feed lines.

-

Along the scrap evacuation and collection paths.

-

Near sorting, welding, and inspection stations.

-

In CNC or machining centers, handling metal parts.

MPI’s magnetic and scrap handling solutions help automotive, appliance, construction, and industrial OEMs run cleaner, safer, and more efficient metalworking operations. By automating scrap removal, improving material control, and protecting equipment, MPI:

-

Reduces downtime and die damage.

-

Improves productivity and part accuracy.

-

Enhances worker safety and ergonomics.

-

Supports lean, automated manufacturing environments.

-

Increases scrap recovery and operational ROI.

Turnkey Solutions for Metal Stamping and Fabrication From Magnetic Products, Inc

-

Maximizes Uptime Through Automated Scrap Handling

Electric scrap shakers and magnetic conveyors remove scrap continuously, preventing manual cleanout delays and allowing presses to run longer.

-

Prevents Die and Press Damage

Tramp metal or lingering scrap can damage tooling; MPI solutions eliminate leftover slugs or offcuts from forming areas to protect high-value assets.

-

Improves Worker Safety and Ergonomics

MPI systems help eliminate slip hazards and minimize the direct handling of sharp, heavy materials by automating scrap removal and reducing floor clutter.

-

Supports Lean and Robotic Operations

MPI products integrate into robotic press lines, destackers, and high-speed automation systems, keeping material flow clean and controlled.

-

Reduces Equipment Downtime and Maintenance

Captured scrap is isolated and managed without contaminating moving parts or clogging chutes, increasing productivity and reducing unscheduled service.

-

Improves Part Flow and Accuracy

Sheet separators and part-handling magnets reduce double-sheet errors, ensure clean blanks, and help correctly guide parts into pick-and-place tooling.

-

Quiet, Energy-Efficient Alternatives to Air Shakers

Electric scrap shakers offer a low-noise, low-maintenance solution that outlasts traditional air-powered systems while reducing energy costs.

-

Customizable to Fit Existing Press Pits and Fabrication Lines

MPI solutions are available in modular or custom-engineered designs to retrofit legacy equipment or support expansion of automated stamping lines.

How Does the Metal Stamping and Fabrication Industry Use Magnets and Industrial Conveyors?

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

| Electric Scrap Shakers (M-10 and M-50 Series) | Under stamping presses, die stations, or turret punch tables | Automatically moves scrap and slugs away from production areas. Replaces loud, maintenance-prone pneumatic systems with efficient, long-life electric units. | Continuously during production to prevent scrap buildup | Oscillating magnetic drives move metal along troughs into bins or conveyors |

| Sheet and Plate Separators | Coil-fed and robotic destacking systems | Separate stacked sheet metal blanks to prevent double-sheet feeding. Improves feeding accuracy and protects dies from stacked misfeeds. | At the start of press lines or forming operations | Magnetic force induces a repelling effect between oily sheets |

| Magnetic Conveyors (Beltless or Belted) | Under presses or forming stations, along scrap lines | Transport ferrous parts or scrap without exposed belts or rollers. Ideal for dirty environments with minimal maintenance needs. | Where wet, oily, or abrasive scrap is present | Internal magnets pull metal along a sealed track |

| Magnetic Chutes and Slide Conveyors | Under sloped surfaces or press exits | Guide and capture falling scrap for controlled collection. Cleaner die areas and reduced need for manual bin positioning. | Where space is limited or inclined evacuation is needed | Magnetic zones attract scrap, directing it toward discharge bins |

| Magnetic Pulleys and Drums | At scrap separation or reclaim stations | Automatically separate ferrous scrap from mixed material streams. Improves scrap sorting and recovery for recycling or resale. | After press pits or at reclaim sortation areas | Magnetized pulleys or rotating drums lift and eject metal |

| Magnetic Workholding Tools | Welding, grinding, inspection, or machining stations | Securely hold ferrous parts in place. Improves part quality and reduces operator error. | For repeatable part positioning or during manual fabrication | Switchable or permanent magnets grip workpieces |

| Part Handling Magnets | Manual or robotic pick-and-place systems | Grip and move small ferrous parts cleanly and precisely. Faster, more reliable part transfer with minimal damage. | During loading, transfer, or post-inspection | Magnetic grippers pick up parts, often with quick-release |