MPI Feeder Magnets are designed to remove ferrous contaminants from free-flowing materials at the beginning of processing lines, ensuring downstream equipment protection and product purity. Installed above or within vibratory feeders, belt conveyors, or chutes, these powerful magnets attract and capture tramp metal from powders, granules, and small parts as they are conveyed. Ideal for food, plastics, chemical, and recycling industries, MPI Feeder Magnets offer high-intensity separation in a compact, easy-to-maintain design. With manual or quick cleaning options, they improve product quality, reduce equipment wear, and support regulatory compliance for metal contamination control.

Engineered for applications that necessitate frequent cleaning, the Quick-Clean Rotary Feeder is equipped with a manual pull-and-clean system. This design allows operators to swiftly remove the magnetic core, ensuring that any metal contaminants fall away from the magnet for rapid and effortless cleaning. This efficiency reduces downtime while maintaining effective separation of ferrous materials. It is particularly suited for industries where halting material flow for cleaning is essential. Ideal for operations that demand regular manual cleaning with quick turnaround times.

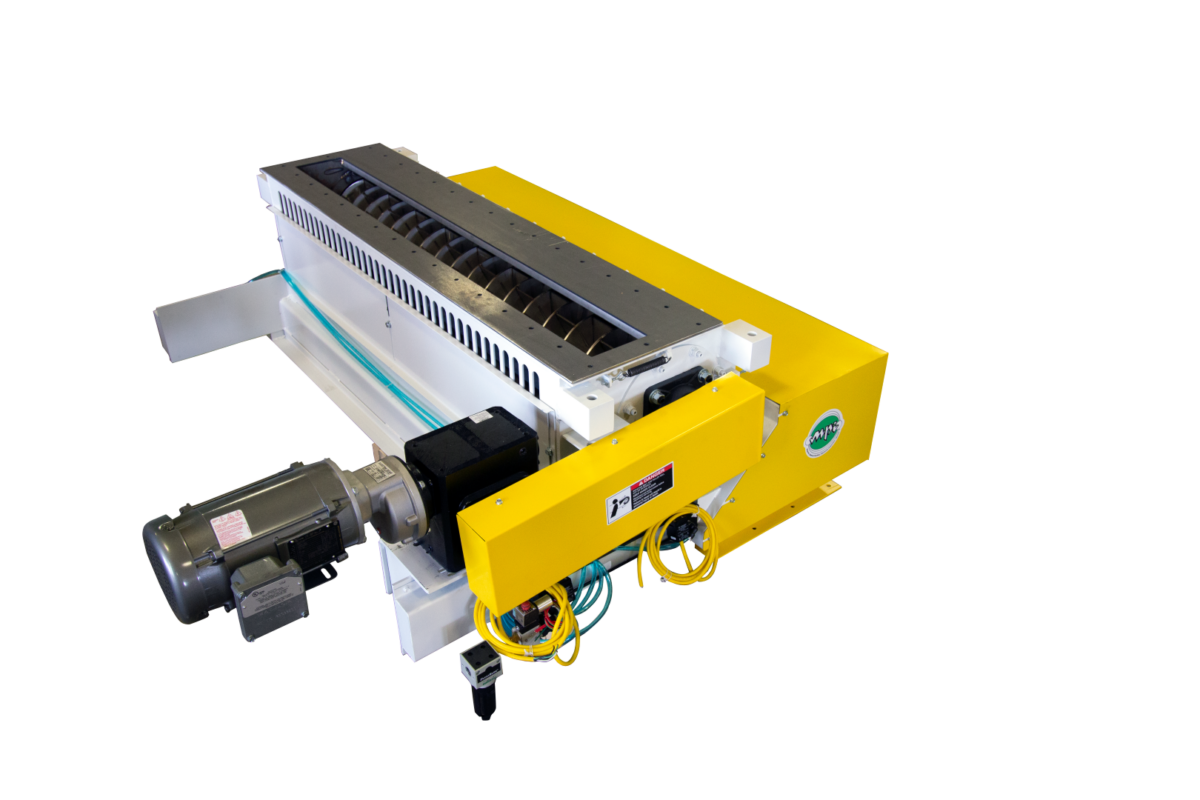

The Self-Cleaning Magnetic Rotary Feeder operates continuously with an automated cleaning system that removes ferrous contaminants without manual intervention. Using a wiper or air-blast mechanism, it ensures a steady material flow and reduces downtime. Built with high-strength rare earth magnets and durable stainless steel, it is ideal for high-capacity processing in industries like food, plastics, and chemicals, enhancing efficiency and minimizing cross-contamination.

Compatibility Check - Feeder Magnet Comparison

Unique Benefits and Considerations

| Free Flow Feed Type | Unique Benefits | Considerations |

|---|---|---|

| Quick-Clean Rotary Magnetic Feeders | Precise material flow control, effective metal separation, easy to maintain. | Requires manual cleaning, leading to periodic stoppages. |

| Self-Clean Rotary Magnetic Feeders | Fully automated operation, minimizes downtime, maximizes efficiency. | Higher cost, more complex system. |

Industries, Applications and Regulations

For assistance in selecting the most suitable feeder magnet for your application or for additional customization options, contact Magnetic Products Inc. at info@mpimagnet.com today to speak with our team of experts!