Tailored for Consistent, Uniform, Evenly Distributed Product Flow

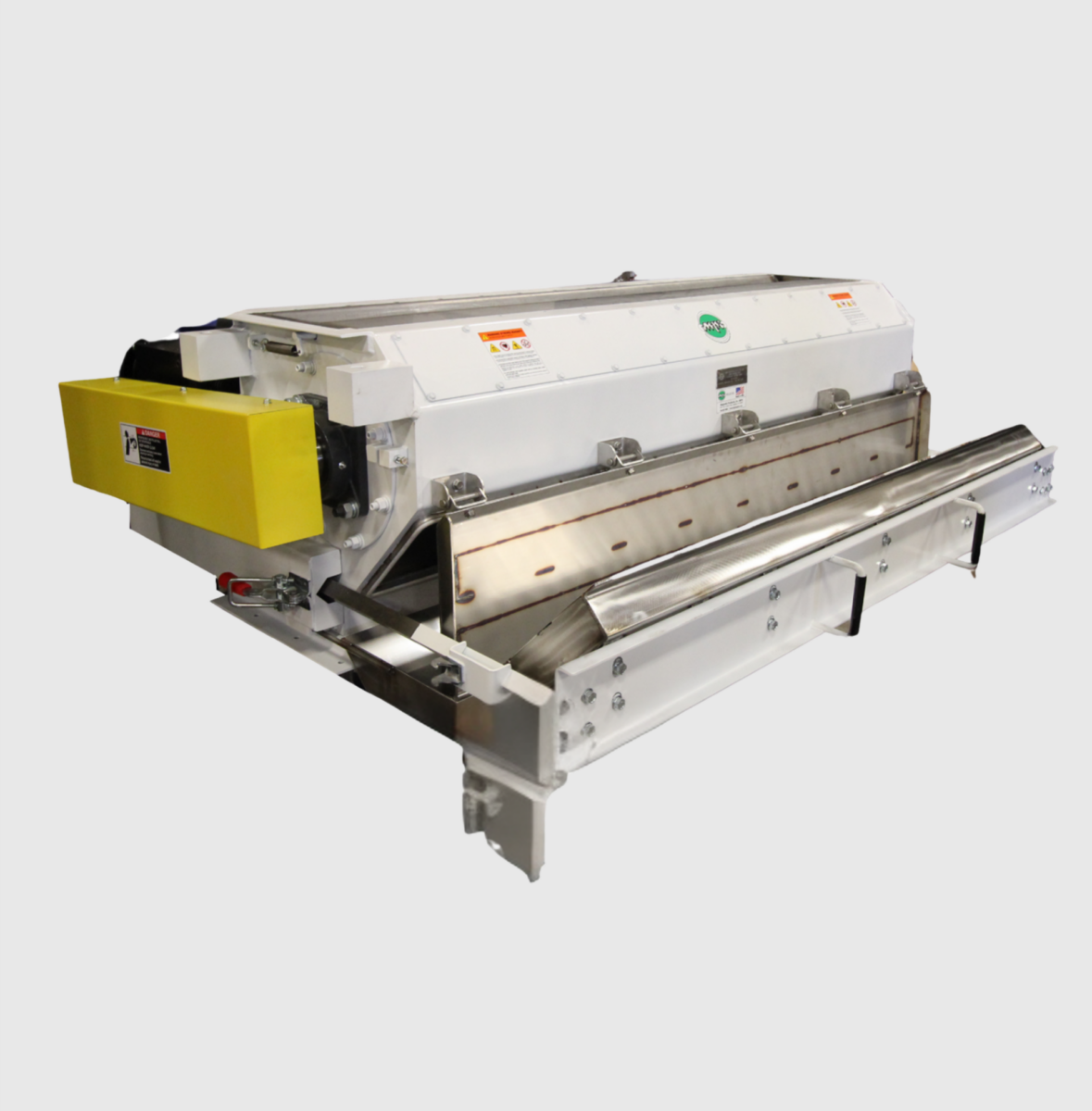

Magnetic Products Inc. (MPI) offers Magnetic Rotary Feeders designed to enhance the reliable and efficient feeding of dry, granular, or powdered materials while effectively extracting ferrous contaminants. These feeders seamlessly integrate into material handling systems across a variety of sectors, such as food processing, pharmaceuticals, plastics, and chemical manufacturing. MPI Magnetic Rotary Feeders combine precise material flow control with high-intensity magnetic separation to improve product purity and protect downstream equipment.

The Quick-Clean Rotary Feeder from MPI is specifically designed to efficiently extract ferrous contaminants from free-flowing bulk materials within pneumatic conveying systems and is tailored for applications that require frequent cleaning. Its manual pull-and-clean system allows for rapid and straightforward cleaning, thus reducing downtime. This feeder is well-suited for applications requiring frequent cleaning to uphold product purity and operational efficiency.

Benefits of the Quick-Clean Magnetic Rotary Feeder From Magnetic Products, Inc

-

Quick-Clean System

Features a manual pull-and-clean system, allowing operators to remove the magnetic core quickly.

-

Heavy-Duty Construction

Engineered for resilience in industrial settings.

-

Compact Design

Easily integrates into existing processing lines.

-

Powerful Rare Earth Magnets

High-intensity magnetic field ensures maximum metal separation. Ensures removal of ferrous contaminants, improving product quality.

-

Adjustable Rotor Speed

Optimizes material flow and separation efficiency.

-

Operator-Friendly

No special tools required for cleaning and maintenance.

Quick-Clean Magnetic Rotary Feeder Product Details

MPI’s Quick-Clean Magnetic Rotary Feeder is designed to efficiently remove ferrous contaminants from free-flowing bulk materials while ensuring smooth and controlled material flow. This feeder is ideal for applications requiring frequent cleaning, minimizing downtime and maximizing operational efficiency.

- Material Flow & Magnetic Separation

- Dry, granular, or powdered materials enter the feeder through the spring-loaded control gate, which ensures a steady, controlled flow.

- The feeder’s high-intensity Ceramic 8 permanent plate magnet captures ferrous contaminants as materials pass through.

- Quick-Clean Mechanism

- When cleaning is required, operators can easily pull the magnetic core from its housing using MPI’s exclusive pull-and-clean system.

- Once removed, trapped metal contaminants automatically fall away from the magnet, allowing for fast and hassle-free cleaning.

- Damage Prevention & Efficiency

- The spring-loaded control gate prevents damage by allowing large metal objects to pass through safely before being captured.

- The system eliminates the need for heavy lifting or extensive manual handling during maintenance.

By integrating Quick-Clean Rotary Feeders, businesses in food processing, pharmaceuticals, plastics, and chemical manufacturing can maintain product purity, protect downstream equipment, and enhance overall production efficiency.

Quick-Clean Magnetic Rotary Feeder Specification Table

US Customary Units

| MODEL # | FEEDER SIZE | (A) INLET/OUTLET OPENING WIDTH (IN.) | (B) FLANGE WIDTH (IN.) | MOTOR HORSEPOWER |

|---|---|---|---|---|

| MRF-103-QC | 3-ROW | 11 | 15.5 | 3/4 |

| MRF-104-QC | 4-ROW | 14.5 | 19 | 3/4 |

| MRF-105-QC | 5-ROW | 18 | 22.5 | 3/4 |

| MRF-106-QC | 6-ROW | 21.5 | 26 | 3/4 |

| MRF-107-QC | 7-ROW | 25 | 29.5 | 1 |

| MRF-108-QC | 8-ROW | 28.5 | 33 | 1 |

| MRF-109-QC | 9-ROW | 32 | 36.5 | 1 |

| MRF-110-QC | 10-ROW | 35.5 | 40 | 1 |

| MRF-111-QC | 11-ROW | 39 | 43.5 | 2 |

| MRF-112-QC | 12-ROW | 42.5 | 47 | 2 |

| MRF-114-QC | 14-ROW | 49.5 | 54.5 | 2 |

Quick-Clean Magnetic Rotary Feeder Customizations and Installations

Quick-Clean Magnetic Rotary Feeder for Animal Nutrition Facility

Large Quick-Clean Rotary Magnetic Feeder for Wheat and Grain Processing

Quick-Clean Magnetic Rotary Feeder for Railway Track Milling Application