Magnetic Products Inc. (MPI) Grate Magnets and Magnetic Tubes are engineered to effectively remove ferrous metal contaminants from various product streams, ensuring product purity and protecting processing equipment. Designed for use in gravity-fed systems, MPI Grate Magnets provide high-intensity magnetic separation in a compact, versatile form, making them ideal for industries such as food processing, plastics, pharmaceuticals, and chemicals. MPI Magnetic Tubes, made in the USA, offer a flexible and efficient solution for capturing small to medium-sized ferrous contaminants in both dry and liquid products. Built for durability, these tube magnets feature fully welded end plugs with 1/4”-20 tapped holes, eliminating the need for crimped or mechanically sealed components. Whether used individually or as part of a grate magnet assembly, MPI’s magnetic solutions deliver superior protection and performance across various applications.

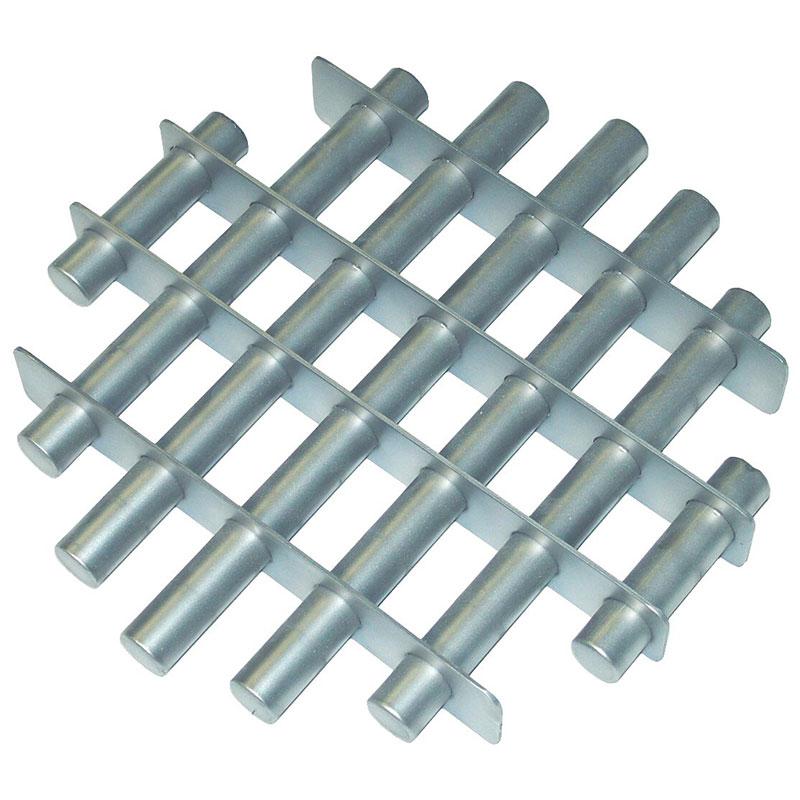

MPI grate magnets are designed to effectively remove medium and small ferrous tramp metal contaminants from dry, granular product streams in various applications like gravity-fed chutes, hoppers, and bins. Known as hopper magnets or magnetic separators, these devices are easy to install and maintain, providing economical magnetic protection for processing equipment such as milling and mixing. The system consists of a series of 1-inch diameter magnetic tubes arranged with 1-inch spacing, supported by a durable welded stainless-steel frame. As contaminants are attracted, they accumulate on the underside of the tubes, preventing any “wash-off.” All components are fully welded for maximum durability, and MPI grate magnets are proudly made in the USA.

MPI magnetic tubes, made in the USA, effectively remove small to medium ferrous tramp metal contaminants from various product streams, including both dry and liquid products. These tubes address contamination caused by metal wear, protecting process equipment and ensuring a high-quality metal-free output. Each tube features fully welded ends with 1/4”-20 tapped holes for durability and easy installation, eliminating the use of crimped or mechanically sealed end plugs. Product streams flow around the 1” diameter tube magnets, capturing contaminants which then settle beneath the tubes, preventing wash-off. Designed for easy cleaning, the tubes provide efficient ferrous metal filtration and can be used individually or in multiple row configurations.

Compatibility Check - Magnetic Grates & Tubes

Unique Benefits and Considerations

| Features/Benefits | Square Grate Magnets | Round Grate Magnets | Magnetic Tubes |

|---|---|---|---|

| Design | Square-shaped, ideal for hoppers and bins with square openings | Round shape, suited for round openings like pipes and chutes | Individual magnetic rods that can be used in various configurations |

| Magnetic Strength | Ceramic or high-intensity rare-earth magnets available | Ceramic or high-intensity rare-earth magnets available | Ceramic or high-intensity rare-earth magnets available |

| Contaminant Capture | Effectively captures ferrous metal contaminants in dry and free-flowing materials | Excellent for fine ferrous contamination in powders, pellets, and granular materials | Strong capture capability, but depends on spacing and arrangement |

| Ease of Installation | Drop-in design for easy installation in square or rectangular openings | Drop-in design for round openings, easy to retrofit | Flexible placement in existing equipment or custom housing |

| Ease of Cleaning | Easy to remove and clean, available in manual or self-cleaning options | Similar to square grates, easy to clean manually or automatically | Can be time-consuming to clean individually |

| Best Use Cases | Dry powders, granules, and free-flowing materials in square or rectangular processing lines | Dry powders, granules, and free-flowing materials in round processing lines | Dry powders, granules, and free-flowing materials in |

| Durability | Made from stainless steel, highly durable | Made from stainless steel, highly durable | Made from stainless steel, highly durable |

| Customizability | Custom sizes and configurations available | Custom sizes and configurations available | Fully customizable in terms of length and arrangement |

Industries, Applications and Regulations

For assistance in selecting the most suitable grate magnet or magnetic tube configuration for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!