Magnetic Products Inc. (MPI) Gravity Feed Metal Detectors are state-of-the-art systems specifically engineered to identify and eliminate ferrous, non-ferrous, and stainless-steel contaminants from freely flowing bulk materials. These detectors are perfectly suited for high-volume environments, delivering outstanding sensitivity and dependable performance. They play a crucial role in maintaining product quality and safeguarding downstream equipment across a range of industries, such as food processing, pharmaceuticals, chemicals, and plastics.

Our gravity feed metal detectors, often referred to as drop-through or free-fall metal detectors, are expertly crafted to detect metal contamination in continuously flowing granules or powders. They are optimal for assessing dry, bulk materials, including sugar, flour, plastic granules, gravel, tablets, and capsules, among others.

Equipped with sensitive sensors, the CASSEL Inspection gravity feed metal detectors are capable of identifying even the tiniest metal contaminants. Fast-switching separation flaps promptly remove these contaminants from the product stream during the production process.

All gravity feed metal detectors are custom-designed and can be tailored to meet the specific needs of each production environment.

Gravity feed type metal detectors are used in gravity feed pipes and provide the highest performance in detecting magnetic and non-magnetic metals. Ideal for powdered, granular, or free-flowing bulk materials, these detectors ensure contaminant removal without interrupting product flow. They are commonly used in food, pharmaceutical, chemical, and plastics industries where precision and product purity are critical.

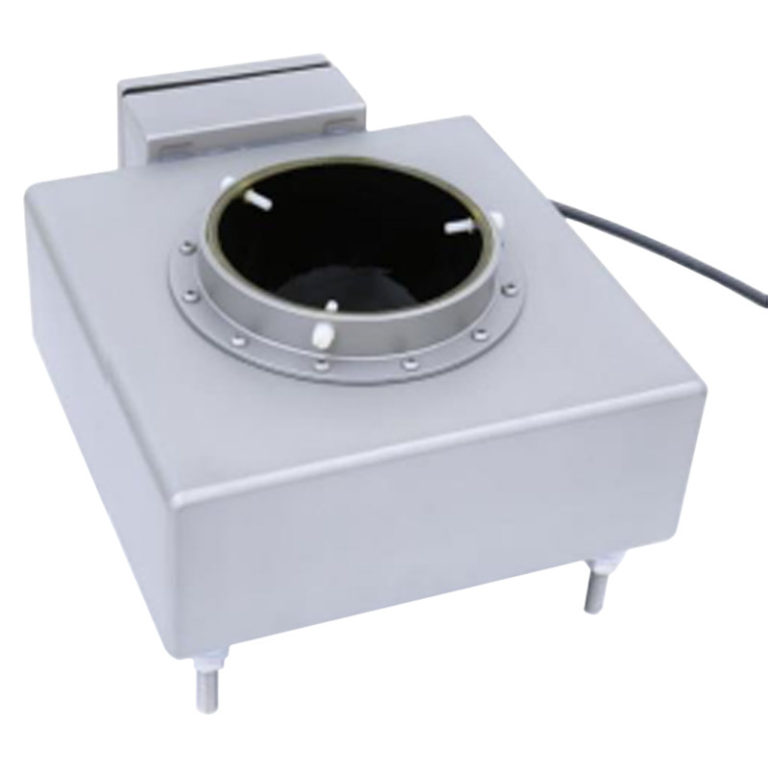

The Compact Gravity Feed Metal Detector has a low assembly height and is specially designed for limited space applications in free-flowing product lines. Despite its small footprint, it delivers high-sensitivity detection of ferrous, non-ferrous, and stainless-steel contaminants. Its streamlined design makes it ideal for integration into tight processing areas without sacrificing performance or throughput.

Pro-Tector systems combine the excellent ferrous separation performance of a magnet with the non-ferrous and stainless detection of a metal detector, all in one compact unit. This integrated solution offers a powerful first line of defense against metal contamination in bulk material handling. Its space-saving design simplifies installation and maintenance, making it ideal for high-efficiency processing environments where both detection and separation are critical.

The Gravity Packaging Throat Metal Detector is designed for vertical installation in packaging systems, specifically for free-falling products. Positioned between the product hopper and forming tube, it detects ferrous, non-ferrous, and stainless-steel contaminants before sealing. Its compact and hygienic design enables easy integration into existing vertical form-fill-seal (VFFS) lines, ensuring product integrity and maintaining packaging speeds.

The R Sensor type detects magnetic and non-magnetic metals, making it ideal for use in the medical-pharmaceutical sector, sanitary products, food, and chemical powders. Its design ensures that products fall through the sensor head for optimal performance. The system’s compact footprint and high detection sensitivity make it a reliable choice for integrating gravity-fed processing lines with strict quality requirements.

METAL SHARK® PH types are used at the outlet of a tablet press and provide the highest performance in detecting magnetic and non-magnetic metals. Designed specifically for pharmaceutical applications, they offer ultra-high sensitivity and fast reject response to ensure product safety and regulatory compliance. Their compact, GMP-compliant design integrates seamlessly into tablet production lines without disrupting throughput.

Compatibility Check - Gravity Feed Metal Detector Comparison

Unique Benefits and Considerations

| Gravity Feed Metal Detector Type | Unique Benefits | Considerations |

|---|---|---|

| Gravity Feed Metal Detector | High sensitivity; Ideal for free-falling bulk materials; Compatible with various industries. | Requires sufficient vertical space; May need support frame or customized chute. |

| Compact Gravity Feed Metal Detector | Low-profile design; Perfect for space-constrained installations; Maintains high detection. | Limited throughput compared to full-sized models; Best for lower-volume applications. |

| Pro-Tector | Combines magnetic separation and metal detection; Saves space; Reduces false rejects. | More complex setup; Requires integration of both magnet and detector components. |

| Throat Metal Detector | Designed for vertical form-fill-seal lines; High speed; Integrates well with packaging equipment. | Not suitable for non-packaging systems; Limited to certain machine configurations. |

| Metal Detector R (Ring Sensor) | Compact and reliable; Suited for powdered and fine product applications; Easy integration. | Smaller aperture limits material flow size; Mostly for low to medium capacity lines. |

| Metal Detector PH (Pharma) | Ultra-high sensitivity; GMP-compliant design; Ideal for tablets and capsules in pharma environments. | Specialized for pharmaceutical use only; Higher cost and validation requirements. |

Industries, Applications and Regulations

For assistance in selecting the most suitable gravity metal detection solution for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!