Ideal for Heavy Product Flows

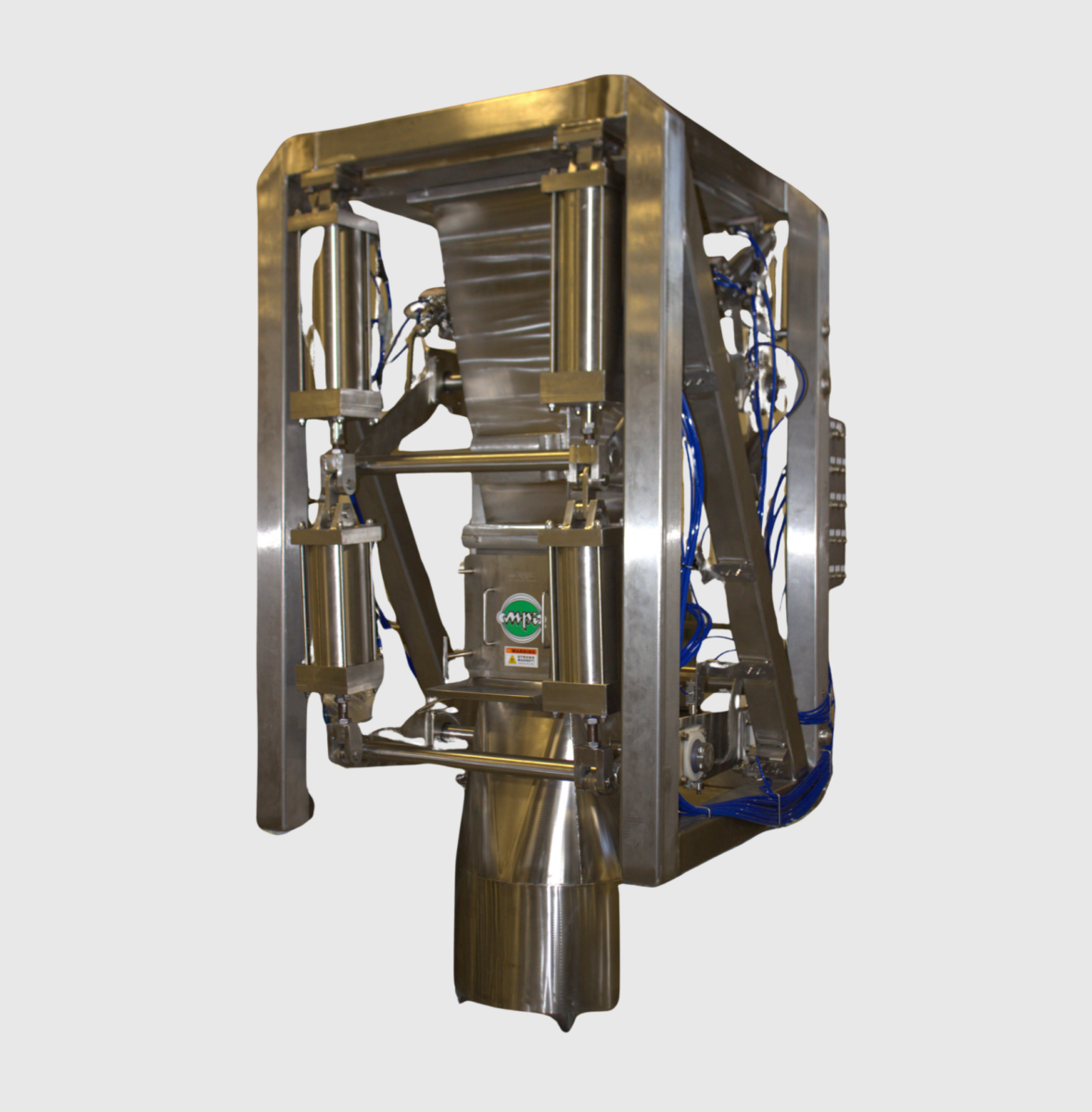

Magnetic Products Inc. (MPI) Manual-Clean Chute Magnets are expertly crafted to efficiently eliminate tramp metal contaminants from free-flowing materials in vertical or nearly vertical chute settings. These magnets are specifically designed for high-volume, gravity-fed product flows, successfully capturing medium to large ferrous contaminants in vertical chutes for materials such as grain, chemicals, food, and powders that may bridge or choke if passed through magnetic grates. By preventing metallic contamination in granular, powder, or bulk material flows, these magnets protect processing equipment and enhance product purity. They are ideal for industries including food processing, plastics, mining, and pharmaceuticals. Reliable, durable, and easy to maintain, MPI's Manual-Clean Chute Magnet is the most powerful option available.

Benefits of the Manual-Clean Chute Magnet From Magnetic Products, Inc

-

High-Strength Magnetic Circuit

Incorporates powerful rare-earth magnets to capture even the smallest ferrous particles.

-

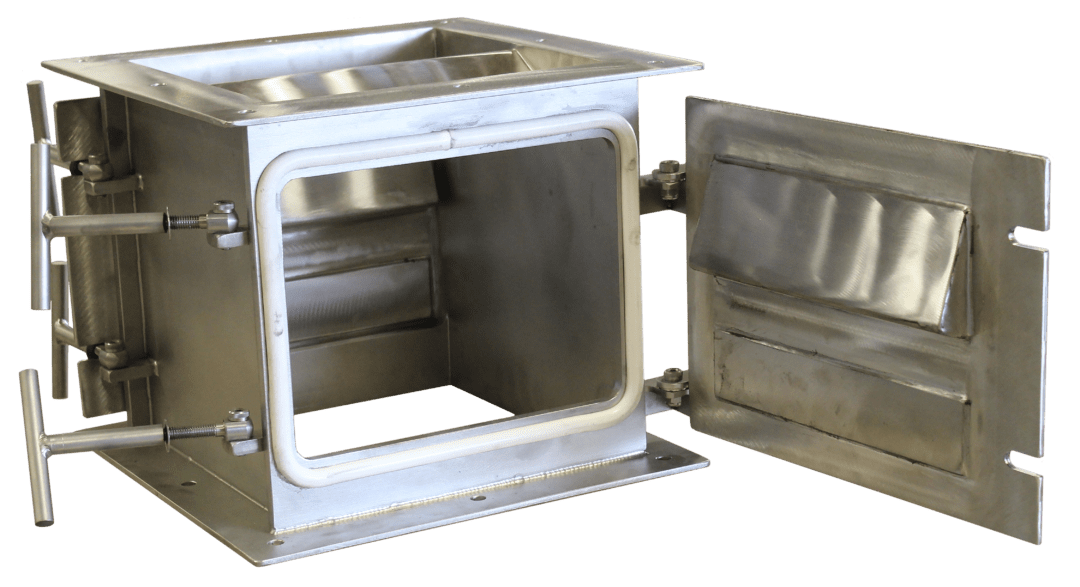

Durable Construction, Compact Design

Built with high-quality stainless steel for maximum durability and resistance to corrosion.

-

Customizable Sizes

Available in a variety of sizes to accommodate specific applications.

-

Easy Manual Cleaning

Simple and quick cleaning process reduces downtime and ensures operational efficiency.

-

Zero-Leak Gasket

Exclusive Sani-TIGHT Seal gasket design eliminates leaks and reduces gasket replacement.

-

FDA-Compliant Models

Options available for food-grade applications.

Manual-Clean Chute Magnet Product Details

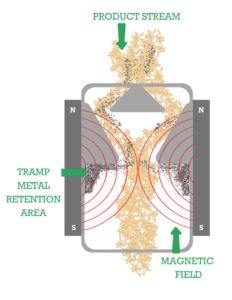

The MPI Manual-Clean Chute Magnet is installed within a chute or vertical material flow system. As material flows through the chute, the magnet creates a strong magnetic field that attracts and holds ferrous contaminants, preventing them from proceeding downstream.

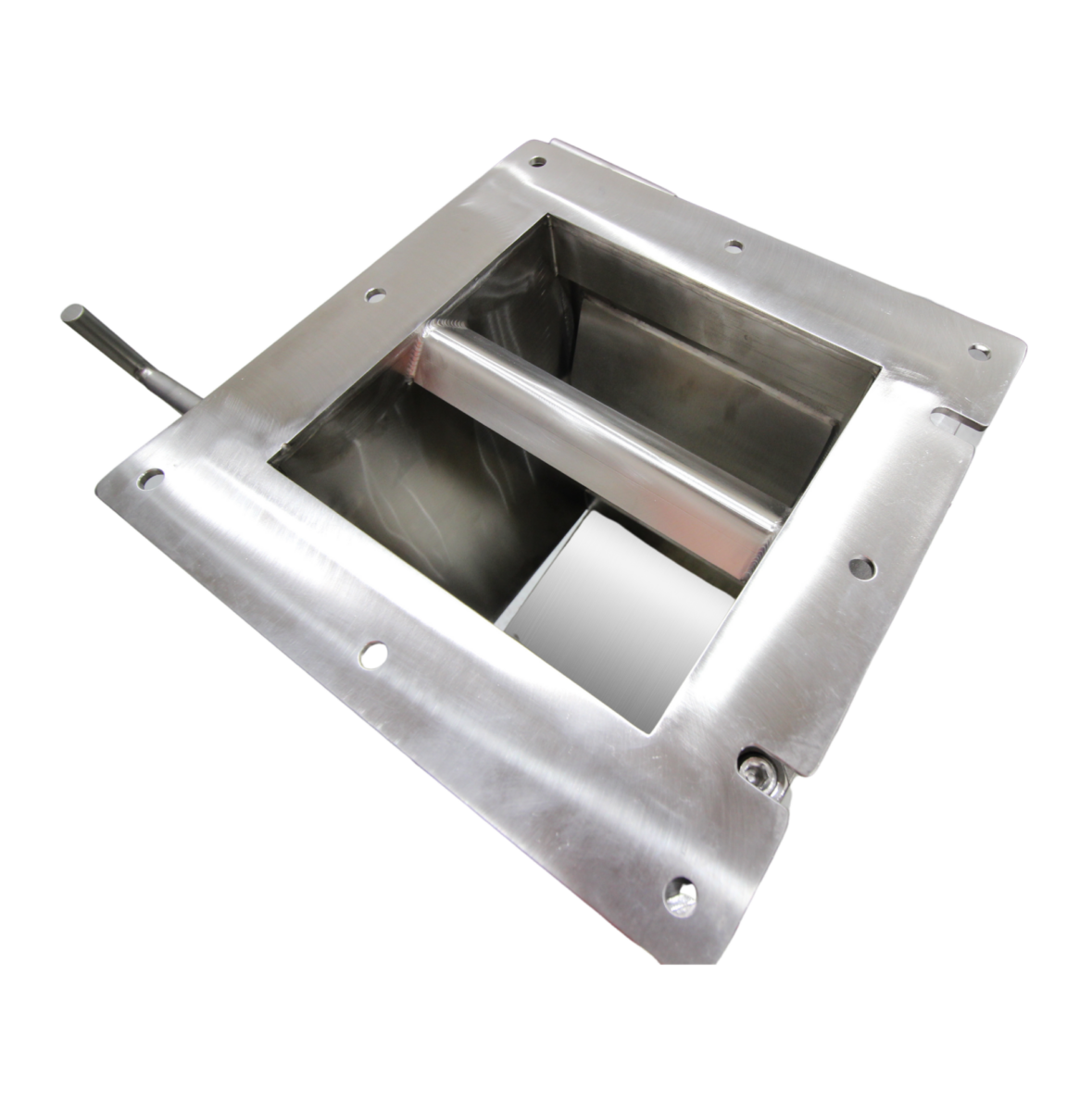

As product moves through the chute, it passes between two high-strength permanent plate magnets positioned on either side. These magnets generate an intense magnetic field, effectively attracting and capturing ferrous contaminants, including screws, bolts, metal shavings, and other tramp metal debris.

A strategically placed center diverter ensures efficient metal separation by directing the product stream toward the working surfaces of the stepped plate magnets. The stepped design enhances metal retention by minimizing tramp metal "wash-off," preventing contaminants from re-entering the product flow.

Tramp metal contaminants are captured from the product stream as it flows through the chute.

The MPI Manual-Clean Chute Magnet is designed to remove ferrous contaminants from free-flowing material within a vertical chute or gravity-fed process system. This system prevents tramp metal from contaminating downstream equipment or final products.

Periodically, operators manually clean the magnet by removing and discarding the trapped metal contaminants. This ensures consistent operation and optimal magnetic performance.

To maintain optimal performance, operators must periodically clean the chute magnet. This process involves:

- Accessing the magnet – The cleaning shell or operator safely reaches the captured contaminants within the chute.

- Removing tramp metal – The trapped ferrous debris is manually extracted from the collection area under the plate magnet’s step.

- Disposing of contaminants – Operators discard the collected metal outside the chute in a designated disposal area.

This manual cleaning process ensures continuous operation, maintains the magnet’s effectiveness in capturing unwanted metal particles, and protects downstream processing equipment.

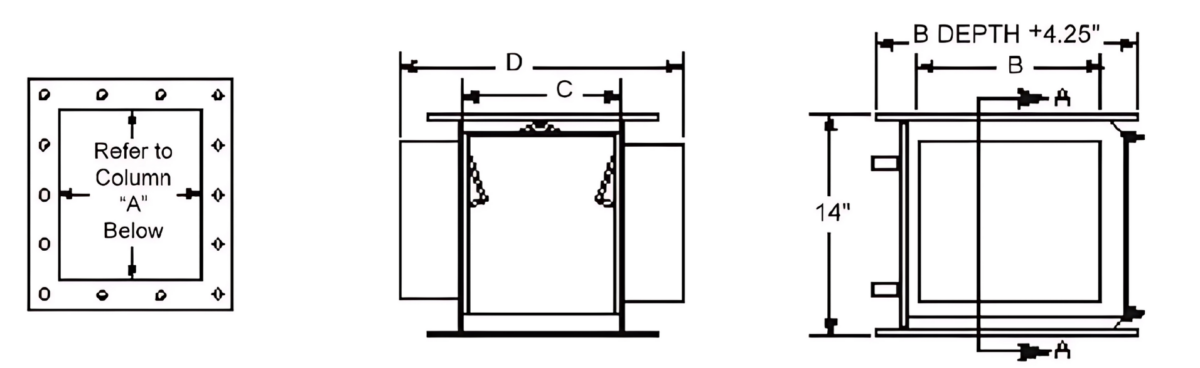

Manual-Clean Chute Magnet Specification Table

US Customary Units

| MODEL # | (B) FLOW OPENING (IN.) | (C) FLOW OPENING (IN.) | OVERALL LENGTH (IN) | APPROX. WEIGHT (LBS) | FLOW RATE (FT³/HOUR) |

|---|---|---|---|---|---|

| MC-808 | 8 | 8 | 12.25 | 154 | 1,200 |

| MC-810 | 10 | 8 | 14.25 | 192 | 1,500 |

| MC-812 | 12 | 8 | 16.25 | 231 | 2,000 |

| MC-1010 | 10 | 10 | 14.25 | 195 | 2,200 |

| MC-1012 | 12 | 10 | 16.25 | 233 | 2,500 |

| MC-1014 | 14 | 10 | 18.25 | 272 | 3,000 |

| MC-1016 | 16 | 10 | 20.25 | 311 | 3,500 |

| MC-1018 | 18 | 10 | 22.25 | 350 | 4,000 |

| MC-1020 | 20 | 10 | 24.25 | 389 | 5,000 |

| MC-1022 | 22 | 10 | 26.25 | 428 | 6,000 |

| MC-1024 | 24 | 10 | 28.25 | 467 | 7,000 |

| MC-1026 | 26 | 10 | 30.25 | 506 | 8,000 |

| MC-1028 | 28 | 10 | 32.25 | 545 | 10,000 |

| MC-1030 | 30 | 10 | 34.25 | 584 | 11,500 |

| MC-1032 | 32 | 10 | 36.25 | 622 | 13,300 |

| MC-1034 | 34 | 10 | 40.25 | 661 | 15,200 |

| MC-1036 | 36 | 10 | 42.25 | 700 | 17,000 |

Manual-Clean Chute Magnet Customizations and Variations

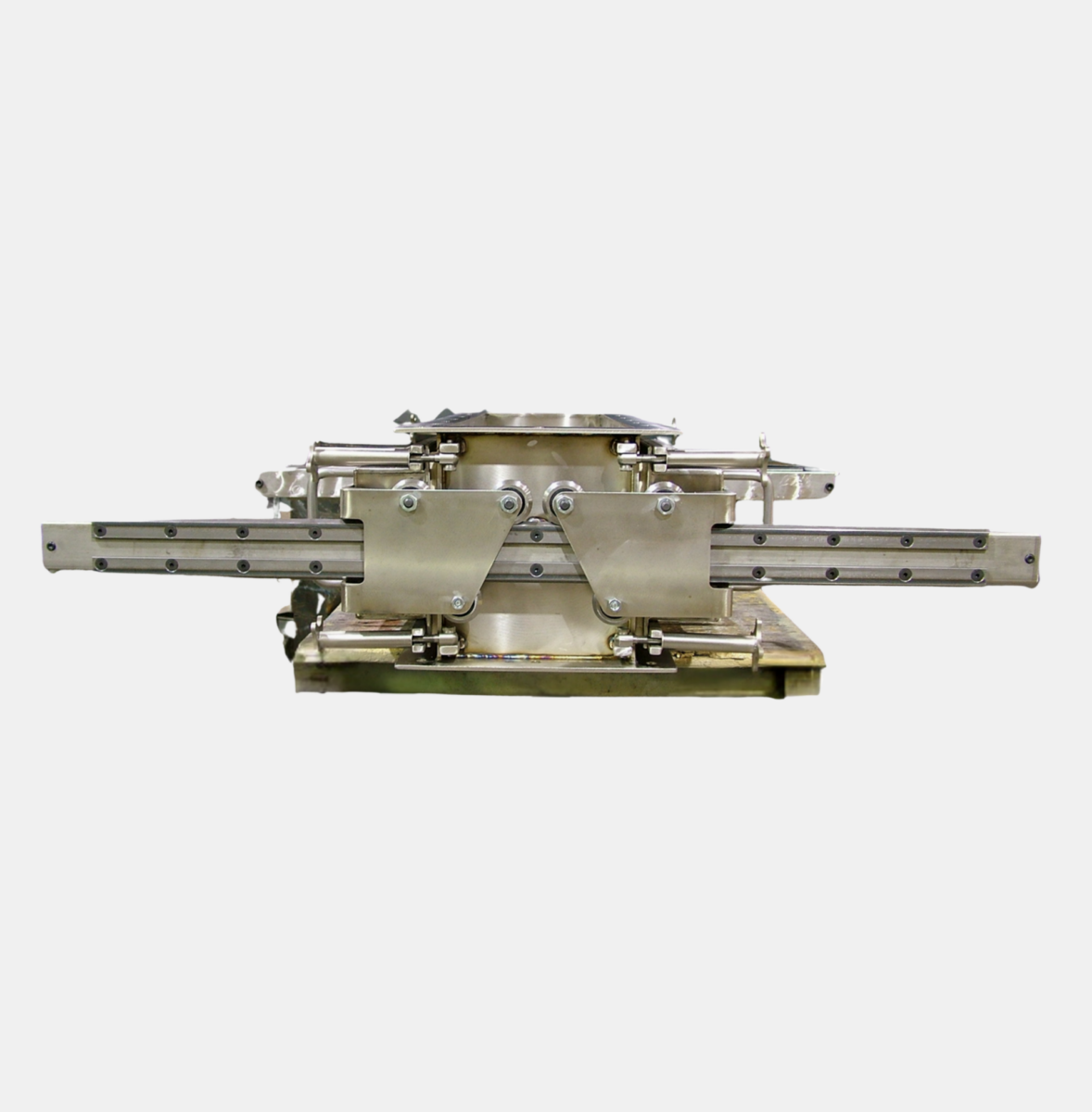

Chute Magnet Designed for Linear Installation

Chute Magnet Engineered for Fine Particle Processing Application

Chute Magnet Designed with Roller Slide for Easy Manual Cleaning