Workhorse for High Volume Product Streams

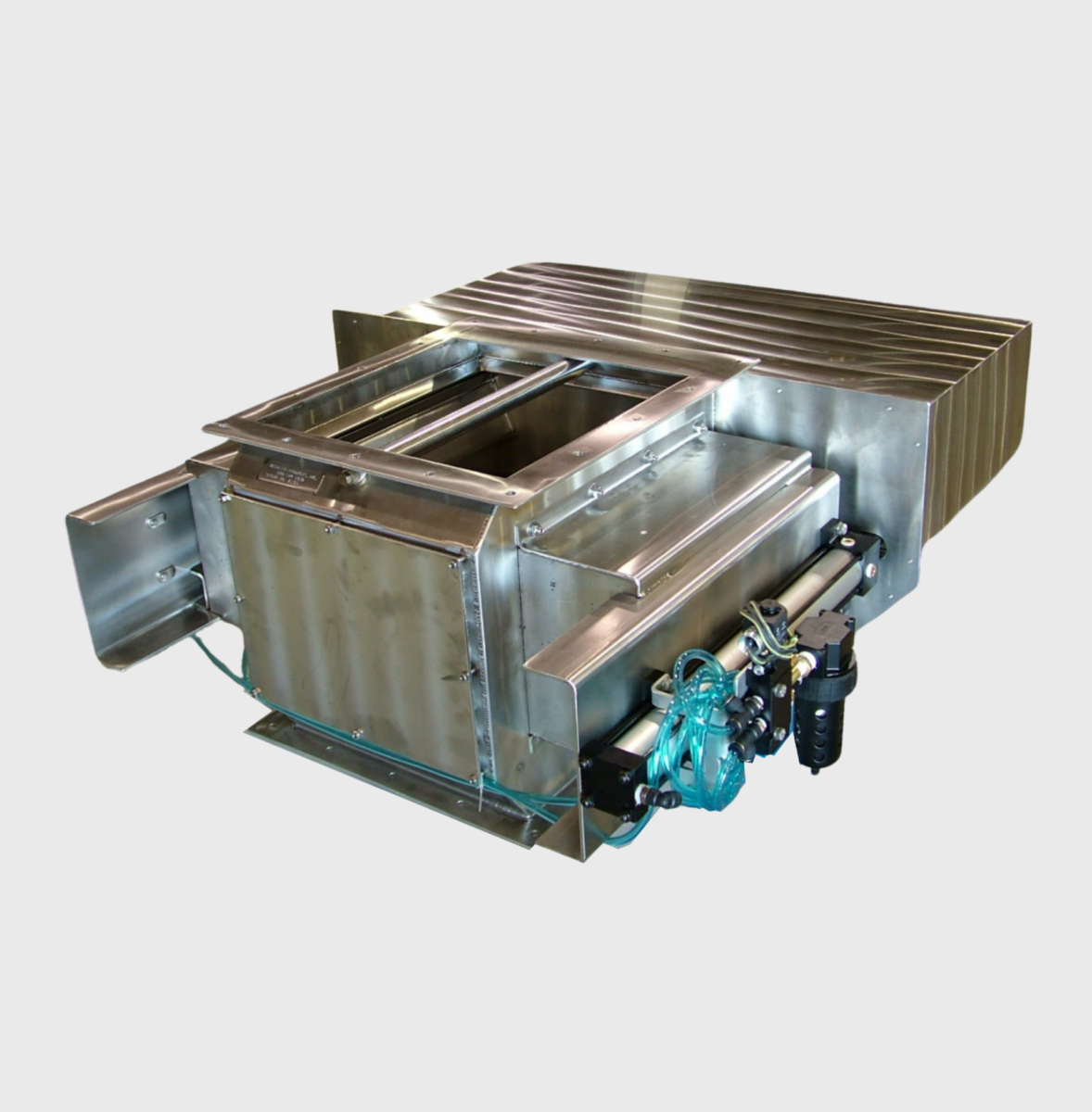

Magnetic Products Inc. (MPI) Self-Clean Chute Magnets are designed for automated and continuous removal of tramp metal contaminants from free-flowing materials in vertical or near-vertical chute applications. These magnets offer a hands-free cleaning mechanism, eliminating the need for manual intervention while maintaining high performance. Ideal for industries such as food processing, pharmaceuticals, recycling, and mining, the self-clean chute magnets enhance productivity, minimize maintenance downtime, and ensure the highest level of product purity and equipment protection.

Benefits of the Self-Clean Chute Magnet From Magnetic Products, Inc

-

Automatic Cleaning Mechanism

Eliminates manual cleaning with a timed or sensor-based cleaning cycle, ensuring uninterrupted operation and reducing labor costs.

-

Powerful Magnetic Circuit

Utilizes high-strength Ceramic 8 or rare-earth magnets to effectively capture both fine and coarse ferrous contaminants.

-

Heavy-Duty, Hygienic Construction

Built with robust stainless steel for durability and corrosion resistance in demanding environments. FDA-compliant food-grade options are available for sanitary applications.

-

Sani-TIGHT Seal™ Gasket

The compression-style O-ring gasket provides a 100% positive seal, preventing over-compression and allowing for easy, adhesive-free removal during washdowns.

-

Continuous Operation

Designed for uninterrupted operation, reducing downtime and labor costs.

-

Compact and Flexible Design

Fits easily into existing chute systems with minimal modification.

-

Food-Grade Options

FDA-compliant models available for food and pharmaceutical applications.

-

Advanced Contaminant Capture

Center diverter and stepped magnetic faces enhance metal separation efficiency for superior tramp iron removal.

-

Enhanced Safety & Reliability

Equipped with safety guards, air filters, and NEMA 9 enclosed solenoids to ensure compliance with industrial standards.

Self-Clean Chute Magnet Product Details

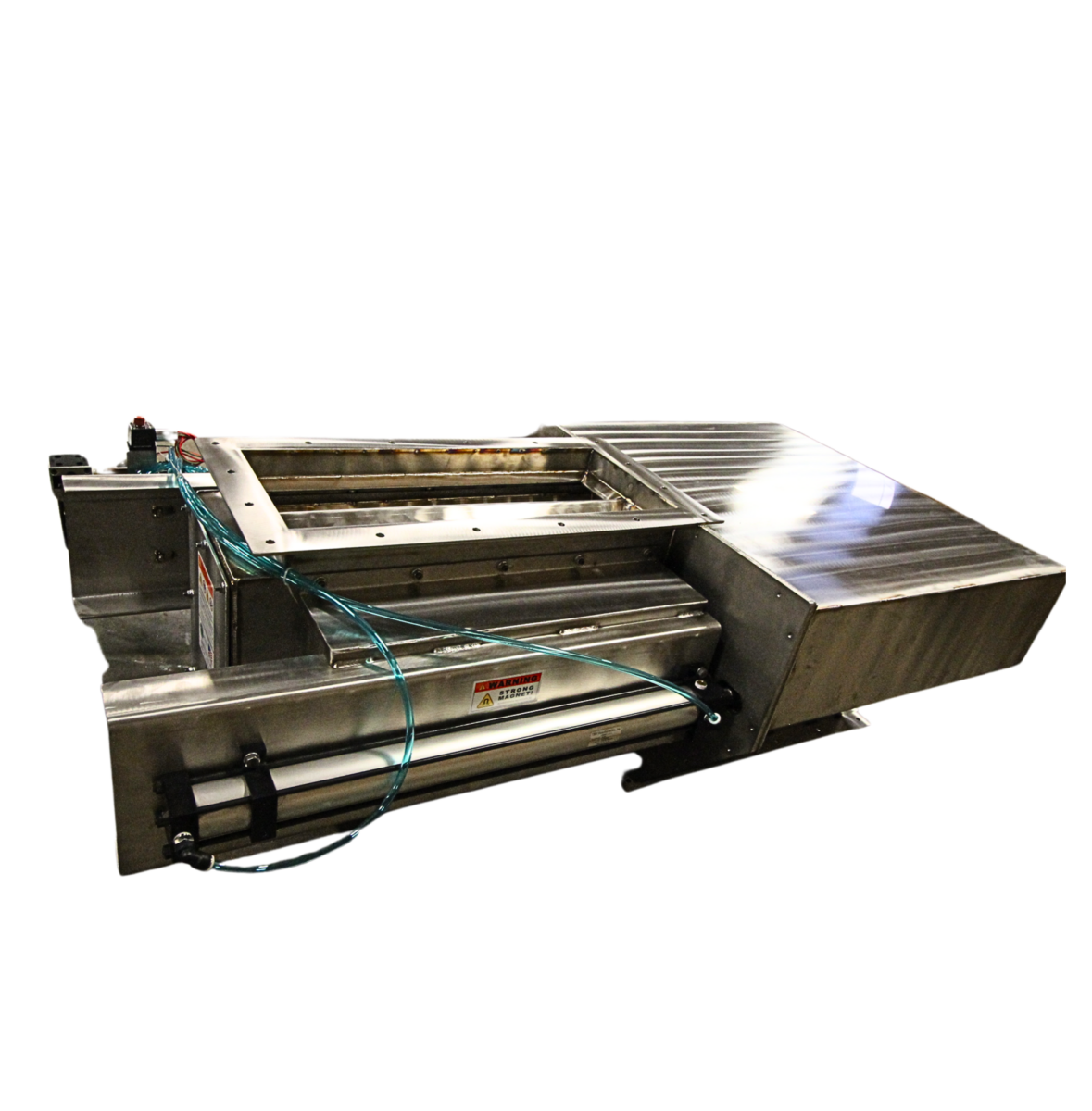

The MPI Self-Clean Chute Magnet is engineered for continuous, automated removal of ferrous contaminants in vertical or near-vertical chute applications. Featuring robust Ceramic 8 permanent magnets, this system effectively captures and holds metal debris, thereby ensuring product purity and safeguarding downstream machinery. Its pneumatically operated self-cleaning mechanism, managed by a timer or sensor, eliminates the necessity for manual maintenance while allowing for uninterrupted material flow.

Designed for installation in vertical or near-vertical chutes, MPI Self-Clean Chute Magnets intercept and retain ferrous contaminants as material moves through the chute. The magnetic field generated by the magnets attracts and secures metal objects. The self-cleaning mechanism regularly removes the captured contaminants without halting the material flow. This automated cleaning process, governed by a timer or sensor, ensures reliable operation while minimizing manual upkeep.

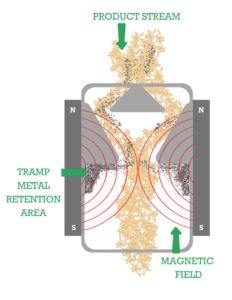

Product flow occurs between two large permanent plate magnets positioned on either side of the chute. A center diverter channels the product toward the working surfaces of these plate magnets, which are stepped to reduce tramp metal "wash-off." Contaminants are collected under the stepped design of the plate magnet, and the cleaning shell or operator safely removes any trapped metal to a disposal area outside the chute.

As the material advances through the chute, it passes between two large, high-strength permanent plate magnets that generate a powerful magnetic field, attracting and securely holding ferrous contaminants such as screws, bolts, metal shavings, and other debris.

The center diverter enhances the separation process by directing the product stream toward the magnets’ active surfaces. The stepped design of the plate magnets prevents the re-release of captured metal, ensuring contaminants remain retained until they are automatically expelled.

The self-cleaning mechanism operates continuously without interrupting the material flow, following these essential steps:

-

Detection & Retention – Ferrous contaminants are drawn to and held by the plate magnets as the product flows past.

-

Pneumatic Cleaning Cycle Initiation – A programmed pneumatic cleaning shell activates at predetermined intervals or upon sensor detection.

-

Metal Contaminant Removal – The cleaning shell retracts automatically, dislodging and transporting trapped tramp metal to a designated disposal area outside the chute.

-

Magnet Reset for Continuous Operation – The system quickly resumes its active state, ensuring smooth material processing.

By automating the cleaning procedure, the MPI Self-Clean Chute Magnet minimizes downtime, reduces manual intervention, and guarantees consistent and efficient metal removal. This leads to improved product quality, enhanced operational efficiency, and superior protection of equipment in industrial processing environments.

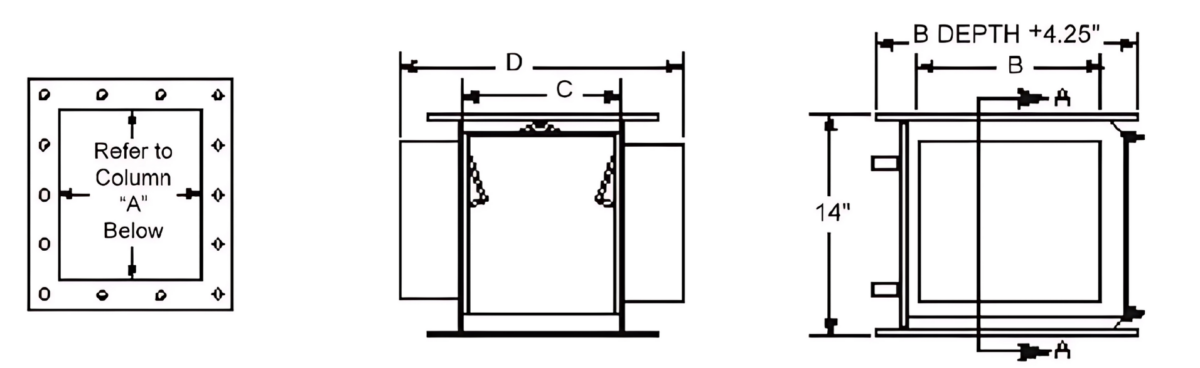

Self-Clean Chute Magnet Specification Table

US Customary Units

| SELF-CLEAN CHUTE MAGNET MODEL # | FLOW OPENING (A) - IN | OVERALL LENGTH (B) - IN | APPROX. WEIGHT- LBS | FLOW RATE - FT3/HR |

|---|---|---|---|---|

| MC-1010-SC | 10 | 36 | 215 | 2,200 |

| MC-1012-SC | 12 | 40 | 258 | 2,500 |

| MC-1014-SC | 14 | 44 | 301 | 3,000 |

| MC-1016-SC | 16 | 48 | 344 | 3,500 |

| MC-1018-SC | 18 | 52 | 387 | 4,000 |

| MC-1020-SC | 20 | 56 | 430 | 5,000 |

| MC-1022-SC | 22 | 60 | 473 | 6,000 |

| MC-1024-SC | 24 | 64 | 516 | 7,020 |

| MC-1026-SC | 26 | 68 | 559 | 8,500 |

| MC-1028-SC | 28 | 72 | 602 | 10,000 |

| MC-1030-SC | 30 | 76 | 645 | 11,500 |

| MC-1032-SC | 32 | 80 | 688 | 13,300 |

| MC-1034-SC | 34 | 84 | 731 | 15,200 |

| MC-1036-SC | 36 | 88 | 774 | 17,000 |

Self-Clean Chute Magnet Customizations and Variations

Self-Clean Chute Magnet Developed for Carbon and Graphite Manufacturing

Self-Clean Chute Magnet Used in Aquaculture