Ideal for High Volume Production and Product Applications Prone to Bridging

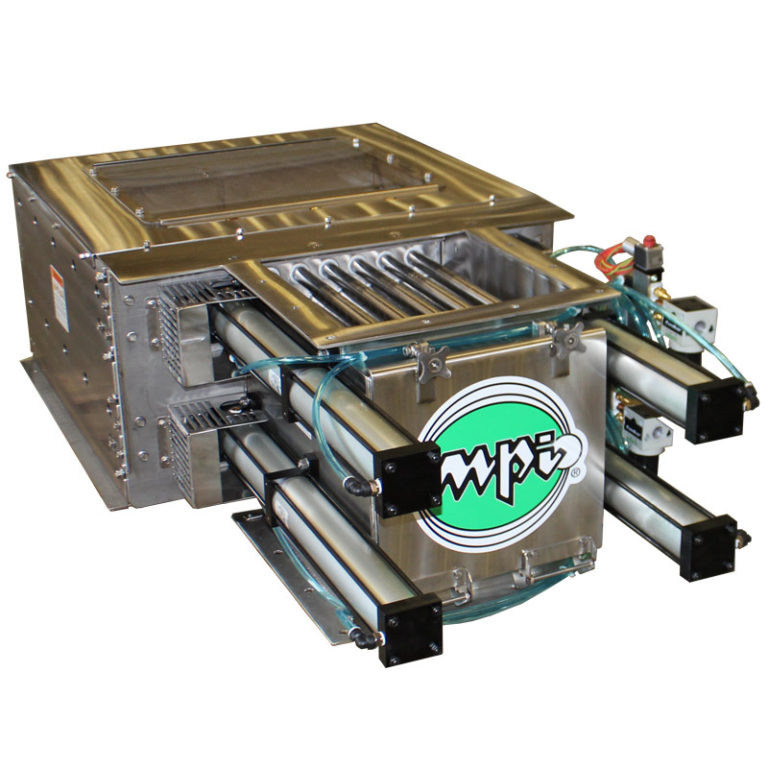

Magnetic Products Inc.'s 2" Continuous-Clean Drawer Magnets are designed to efficiently remove ferrous contaminants from dry powders and granular materials in industrial settings. Featuring multiple rows of 2-inch magnetic tubes, these magnets utilize MPI’s patented Intell-I-Mag® technology to create a strong magnetic field that captures small to medium ferrous debris. The design accommodates constant operation in high-contamination environments, ensuring effective tramp metal removal from vertical chutes.

With four tiers of magnets accessible via independent doors, the system enables cleaning without disrupting product flow, protecting milling, extruding, and mixing equipment. The high-intensity rare earth magnetic tubes are strategically arranged to prevent product bridging while maximizing filtration.

The continuous-cleaning mechanism ensures uninterrupted operation by using pneumatically controlled cylinders to extract and discharge collected metal contaminants. As tramp metal accumulates on the magnetic tubes, an automated sequence retracts them through a stripper assembly, efficiently removing debris and directing it into a designated discharge area. This automated cycle resets rapidly, allowing for ongoing filtration while reducing maintenance requirements and downtime in demanding processing environments.

Benefits of the Two Inch Tube Continuous-Clean Drawer Magnet From Magnetic Products, Inc

-

Equipped with Intell-I-Mag®

Enhances operational efficiency by reducing the need for processing line shutdowns for magnet inspections. This system features integrated sensors integrated that link to a dashboard and app, notifying operators when magnet saturation is reached. Cleaning assessments can be conducted without interrupting production, decreasing maintenance downtime and improving efficiency.

-

Continuous Product Flow & Automated Cleaning Cycle

No need to stop product flow during the magnet cleaning cycle, ensuring uninterrupted processing. Reduces manual labor and downtime with an efficient, solenoid-actuated cleaning process.

-

Easy Maintenance and Access

Rear access panel and bolt-on stainless steel safety cage simplify inspection and testing.

-

Enhanced Product Protection

Two magnet rows remain active while cleaning, maintaining product safety at all times.

-

Durable and Hygienic Design

Stainless steel construction with a Sani-TIGHT Seal™ gasket ensures long-lasting, sanitary operation.

-

Leak and Misalignment Prevention

Extended drawer front minimizes product leakage, while internal supports prevent misalignment.

-

Static Discharge Protection

Integrated grounding strap prevents static buildup, enhancing operational safety.

Two Inch Tube Continuous-Clean Drawer Magnet Product Details

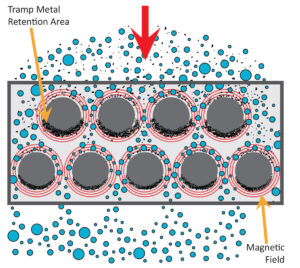

The 2" Continuous-Clean Draw Magnet ensures efficient metal separation by channeling product flow through a staggered array of high-intensity magnetic tubes. These tubes create a powerful magnetic circuit, capturing and retaining ferrous contaminants while preventing product bridging or choking.

During the automated cleaning cycle, pneumatically controlled cylinders sequentially retract one of the two magnetic tube drawers, pulling it through a stripper assembly to safely remove collected tramp metal outside the product stream. While one drawer is being cleaned, the other remains in operation, ensuring continuous product flow without interruption. This seamless, automated process maintains peak filtration efficiency while minimizing downtime and manual intervention.

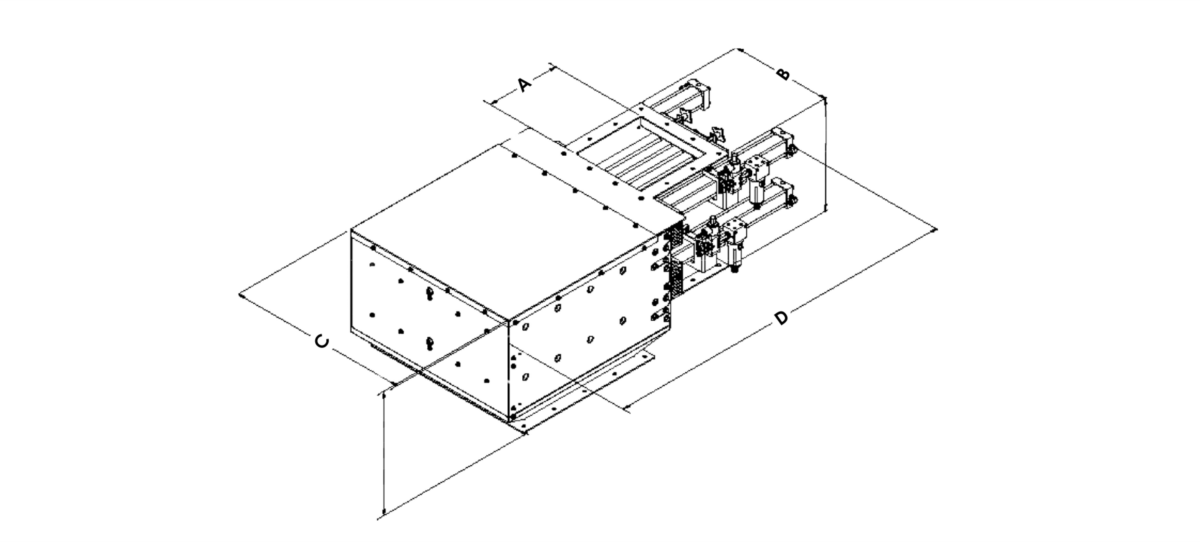

Two Inch Tube Continuous-Clean Drawer Magnet Specification Table

US Customary Units

| CONTINUOUS-CLEAN DMU MODEL # | (A) PRODUCT FLOW OPENING AREA (IN.2) | (B) FLANGE WIDTH (IN.) | (C) OVERALL WIDTH (IN.) | (D) OVERALL LENGTH (IN.) | # of MAGNETIC TUBES | APPROX. WEIGHT (LBS) |

|---|---|---|---|---|---|---|

| CFDMU-408-SC | 8 | 12.25 | 25.2 | 49.5 | 14 | 421 |

| CFDMU-410-SC | 10 | 14.25 | 27.2 | 53.5 | 18 | 469 |

| CFDMU-412-SC | 12 | 16.25 | 29.2 | 57.5 | 22 | 517 |

| CFDMU-414-SC | 14 | 18.25 | 31.2 | 61.5 | 26 | 565 |

| CFDMU-416-SC | 16 | 20.25 | 33.2 | 65.5 | 30 | 613 |

| CFDMU-418-SC | 18 | 22.25 | 33.2 | 69.5 | 34 | 661 |

| CFDMU-420-SC | 20 | 24.25 | 35.2 | 73.5 | 38 | 709 |

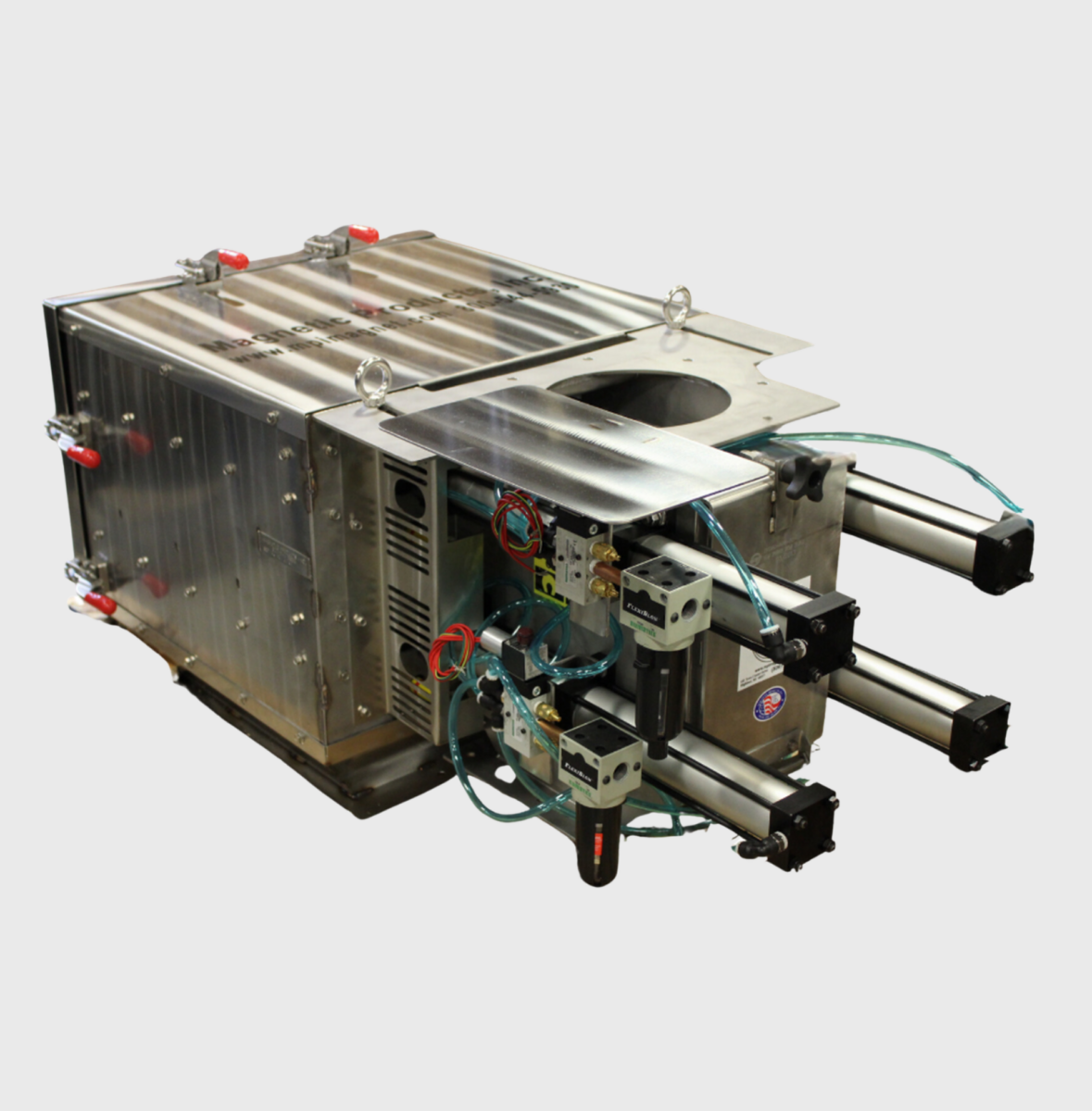

Two Inch Tube Continuous-Clean Drawer Magnet Installations and Variations

2" Continuous-Clean Drawer Magnet for Fine Particle Food Processing

3-Tier, 2" Continuous-Clean Drawer Magnet for High-Volume, Food Processing Prone to Bridging

2" Continuous-Clean Drawer Magnet for High-Volume, Chemical Processing Application