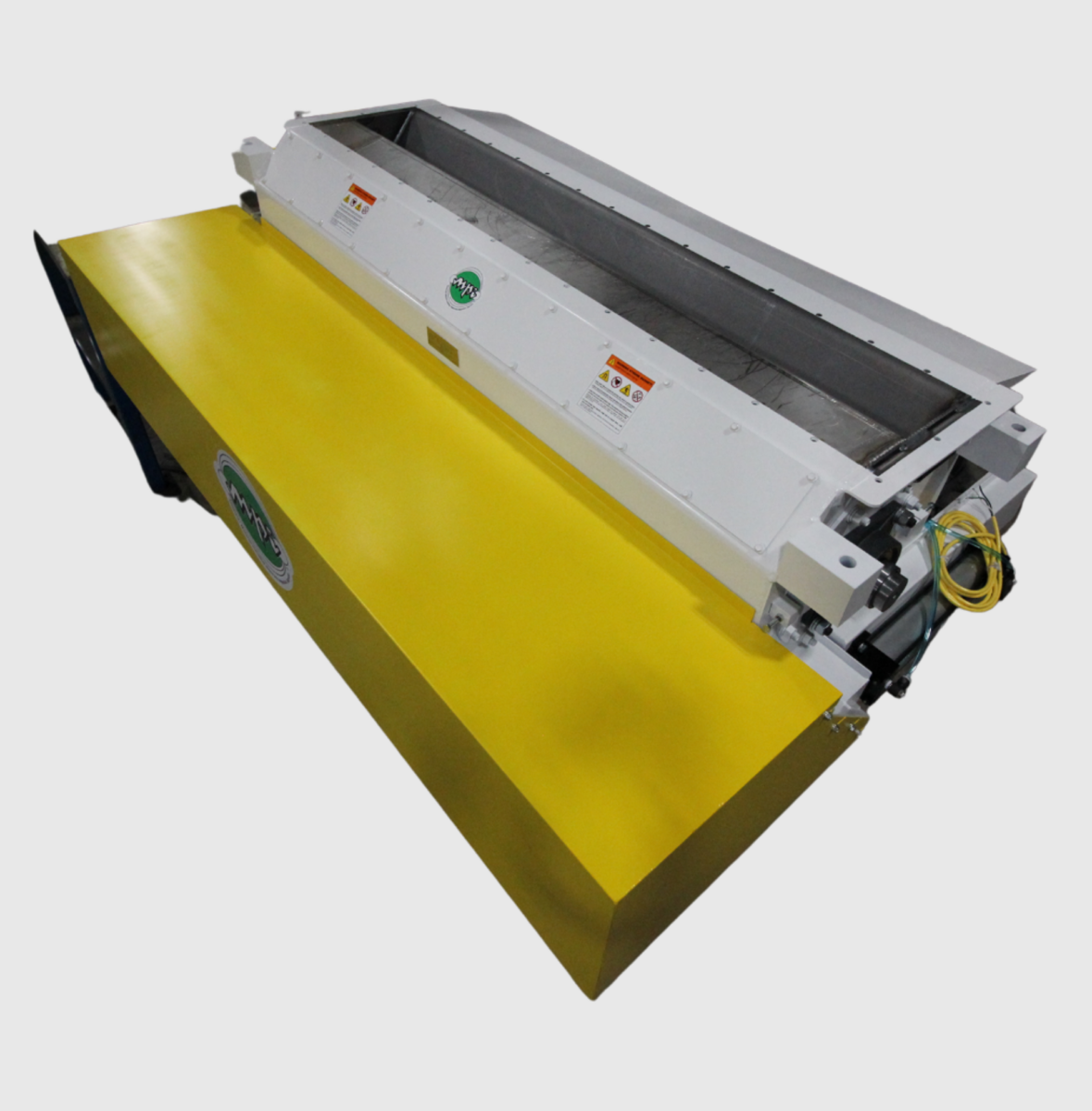

Evenly Distribute Contaminant-Free Feed for Continuous Operation and Minimal Maintenance

The Self-Cleaning Magnetic Rotary Feeder is designed for continuous, automated operation, featuring an autonomous cleaning system that removes ferrous contaminants without manual intervention. It employs a wiper or air-blast mechanism to clear the magnetic surface, ensuring a steady flow of materials and reducing production downtime. Constructed with high-strength rare earth magnets and robust stainless steel, it is durable and effective for high-capacity processing in industries like food, plastics, and chemicals. This feeder enhances production efficiency, cuts labor costs, and minimizes the risk of cross-contamination. For processes requiring frequent manual cleaning, the Quick-Clean Rotary Feeder offers a manual pull-and-clean system for easy maintenance and quick turnaround times.

Benefits of the Self-Clean Magnetic Rotary Feeder From Magnetic Products, Inc

-

High-Intensity Magnetic Circuit

Powerful magnets capture fine and coarse ferrous contaminants to ensure product purity.

-

Protected Rotary Feeding Mechanism

Provides consistent and controlled material flow, minimizing clogging and ensuring operational efficiency. Prevents metal contamination in downstream processing equipment.

-

Durable Construction

Made with high-quality stainless steel for corrosion resistance and long-lasting performance.

-

Continuous Operation, Hands-Free Cleaning

No need to stop production for cleaning. Pneumatic system removes contaminants automatically, reducing manual labor.

-

Customizable Sizes

Available in a variety of sizes to accommodate specific application needs.

-

FDA-Compliant Models

Options available for food-grade applications.

-

Enhanced Safety

The enclosed safety cage prevents exposure to moving parts.

Self-Clean Magnetic Rotary Feeder Product Details

MPI Magnetic Rotary Feeders are installed in material handling systems where controlled feeding and contaminant removal are required. As materials enter the feeder, the rotary mechanism evenly distributes them across the magnetic field created by high-intensity magnetic tubes. The magnets attract and retain ferrous contaminants, ensuring only contaminant-free materials pass downstream. Cleaning processes can be manual or automated, depending on the model, ensuring consistent performance and minimal operator intervention.

- Material Flow & Magnetic Separation

Bulk materials enter the feeder through a spring-loaded control gate, ensuring a steady, regulated flow.

The powerful 400-series Ceramic 8 permanent plate magnet captures and holds ferrous contaminants as materials pass through the system.

- Automated Self-Cleaning Process

The self-cleaning pneumatic system is activated at pre-set intervals or manually as needed.

Pneumatic cylinders automatically retract the magnetic core from the housing, releasing trapped metal contaminants.

As the magnet retracts, ferrous particles fall away and are collected in a designated discharge chute or collection tray, preventing recontamination.

- Safety Cage for Operator Protection

The system is enclosed within a safety cage, preventing accidental exposure to moving parts and ensuring compliance with safety regulations.

The safety cage allows maintenance personnel to perform inspections without risk of injury, making it an operator-friendly design.

- Damage Prevention & Continuous Flow

The spring-loaded control gate protects against damage by allowing large metal objects to pass safely before being captured.

Since the cleaning process is fully automated, there is no need to stop material flow, reducing downtime and improving efficiency.

Self-Clean Magnetic Rotary Feeder Specification Table

US Customary Units

| MODEL # | FEEDER SIZE (IN.) | (A) INLET/OUTLET WIDTH (IN.) | (B) FLANGE WIDTH (IN.) | MOTOR HORSEPOWER |

|---|---|---|---|---|

| MRF-103-SC | 3-ROW | 11 | 15.5 | 3/4 |

| MRF-104-SC | 4-ROW | 14.5 | 19 | 3/4 |

| MRF-105-SC | 5-ROW | 18 | 22.5 | 3/4 |

| MRF-106-SC | 6-ROW | 21.5 | 26 | 3/4 |

| MRF-107-SC | 7-ROW | 25 | 29.5 | 1 |

| MRF-108-SC | 8-ROW | 28.5 | 33 | 1 |

| MRF-109-SC | 9-ROW | 32 | 36.5 | 1 |

| MRF-110-SC | 10-ROW | 35.5 | 40 | 1 |

| MRF-111-SC | 11-ROW | 39 | 43.5 | 1 |

| MRF-112-SC | 12-ROW | 42.5 | 47 | 2 |

| MRF-114-SC | 14-ROW | 49.5 | 54.5 | 2 |

Self-Clean Magnetic Rotary Feeder Installations and Variations

Self-Clean Magnetic Rotary Feeder with Transition for High-Explosion Risk Environment

Extra Large Self-Clean Magnetic Rotary Feeder for Sorghum Manufacturing for Fuel Ethanol, Food, and Livestock Feed

Self-Clean Magnetic Rotary Feeder for Wheat and Millet Processing