Magnetic Separation Solutions for the Aggregate, Minerals, and Mining Industries

MPI’s magnetic separation systems protect equipment, improve product quality, and ensure process efficiency in aggregate, mineral, and mining operations. These environments often process abrasive, high-volume, and metal-laden materials such as sand, gravel, limestone, crushed rock, ores, and recycled concrete. Unwanted tramp iron and ferrous contaminants, introduced through raw material handling, equipment wear, or scrap metal intrusion, can severely damage crushers, screens, conveyors, and mills.

MPI magnets remove these hazards upstream before they cause damage and downstream to ensure final product purity. The goal is to:

-

Prevent costly downtime

-

Extend equipment life

-

Protect belts and crushers

-

Meet customer quality specs

-

Reduce maintenance and risk

Magnetic separators are used throughout the material flow, from receiving and primary crushing to screening, stockpiling, and loading out. Typical placement includes:

-

At infeed conveyors to remove rebar, bolts, or scrap from raw material

-

Ahead of crushers, screens, or grinders to protect wear surfaces

-

After primary or secondary crushing to remove liberated metal fragments

-

Before final stockpile or bagging, to ensure a contaminant-free product

-

At recycling recovery points for concrete, asphalt, or mineral fines

MPI’s solutions provide critical protection and process assurance across the entire mining and aggregate value chain. From reducing downtime and protecting expensive equipment to ensuring high-purity product output, MPI products are purpose-built for tough applications and customizable to your facility’s needs. These systems increase ROI, reduce risk, and support consistent, high-volume production under extreme operating conditions.

Features and Benefits for Aggregate, Minerals, and Mining from Magnetic Products, Inc

-

Heavy-Duty, High-Impact Construction

MPI separators are built with rugged housings, abrasion-resistant liners, and heavy-duty frames to withstand harsh quarry and mining environments with minimal wear.

-

Reliable Tramp Metal Removal

Powerful permanent and electromagnets remove dangerous ferrous materials from the flow, protecting crushers, screens, and conveyor belts from catastrophic damage.

-

Continuous Operation with Minimal Downtime

Self-cleaning and manual-cleaning options allow operators to remove metal without halting material flow, which is essential for 24/7 production in mining and aggregate plants.

-

High-Throughput Efficiency

MPI’s magnetic solutions are designed to handle large material volumes without choking or flow restriction, maintaining peak plant productivity.

-

Field-Configurable Mounting Options

Chute, crossbelt, inline, and overbelt installations allow flexible magnet placement across mobile and fixed plant layouts.

-

Reduced Maintenance Costs

MPI products reduce unplanned maintenance, downtime, and part replacement costs by preventing metal-induced equipment damage.

-

Enhanced Product Quality and Purity

Magnetic separation ensures the final material is free from iron fragments, increasing product value and meeting downstream customer and end-user specifications.

-

Scalable and Customizable Solutions

MPI offers standard and engineered solutions to fit a wide range of belt widths, flow rates, and installation constraints.

How Does the Aggregate, Minerals, and Mining Industry Use Magnets?

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

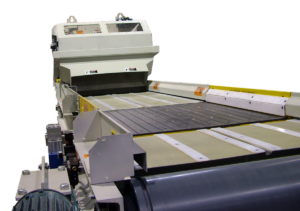

| Electromagnet Suspended Separators (Manual-Clean and Self-Clean) | Suspended over conveyor belts | Removes large tramp metal (wrenches, rebar, bolts) before it reaches crushers or screens | Typically placed at the front of material processing or ahead of high-value equipment | Creates a deep-reaching magnetic field across the belt; self-cleaning models continuously discharge collected metal via a rotating belt |

| Permanent Magnet Suspended Separators (Manual-Clean and Self-Clean) | Over light- to medium-duty belts or portable equipment | Low-power, maintenance-light separation of medium-sized ferrous items | Ideal for mobile crushers, screeners, or remote locations with limited power | Magnet captures metal and holds it until cleaned manually or by belt discharge (self-clean model) |

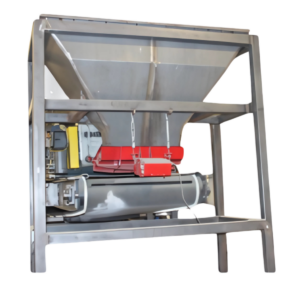

| Drum Separators (Dry and Wet) | Installed inline with product flow (gravity-fed or conveyor-fed) | Separates fine and coarse ferrous material in dry mineral or bulk processing | Often used post-crushing or pre-screening | Ferrous particles are attracted to the rotating drum and carried away from the main product stream |

| Magnetic Head Pulleys | Replaces standard conveyor head pulley | Automatically separates ferrous contaminants as product discharges from the belt | Installed at discharge points, especially in recycling or aggregate blending lines | Magnetic zone on pulley surface attracts metal, which is discharged beneath the belt, while clean material continues forward |

| Crossbelt Separators (Overbelt Magnets) | Mounted across wide conveyors | Enables continuous, automated removal of tramp iron without contact with the material stream | Common in primary and secondary crushing circuits | Ferrous metal is lifted from the product stream and ejected off the side via a transverse cleaning belt |

| Plate Magnets and Magnetic Chutes | Mounted inside gravity-fed chutes or beneath belt transitions | Protects downstream equipment by removing smaller tramp iron | Ideal for flow transitions, scalping decks, or vibrating feeders | Plate surfaces attract metal as material slides or falls past |

| Metal Detectors | Inline with conveyors before high-risk equipment | Detects both ferrous and non-ferrous contaminants not caught by magnets | Often installed in conjunction with magnets as a secondary layer of protection | Triggers alarms or reject mechanisms when metal is detected within the product stream |

Aggregate, Minerals, and Mining Industry Compatible Products from Magnetic Products, Inc

- « Previous

- 1

- 2

- 3

- 4