Conveyance Solutions for Automotive Metal Forming

MPI’s magnetic separation and scrap handling systems are critical in automotive manufacturing environments, especially in facilities that involve metal stamping, welding, machining, powder coating, and assembly operations. These processes generate significant amounts of ferrous scrap, fines, and contaminant particles that must be removed to protect equipment, maintain part quality, and streamline operations.

MPI’s magnetic separation and scrap handling systems are critical in automotive manufacturing environments, especially in facilities that involve metal stamping, welding, machining, powder coating, and assembly operations. These processes generate significant amounts of ferrous scrap, fines, and contaminant particles that must be removed to protect equipment, maintain part quality, and streamline operations.

MPI solutions are used:

-

At stamping lines to remove and manage press scrap safely and efficiently

-

In machining operations, to remove metal fines from coolants and lubricants

-

Ahead of welding and assembly stations to ensure parts are contaminant-free

-

In coating and finishing lines, to prevent defects caused by metal inclusions

They enhance safety, extend equipment life, ensure product quality, and support lean, automated production systems.

MPI magnetic solutions support the automotive sector from metal stamping to final assembly, enabling safe, clean, and efficient production. Whether protecting robotic welders from tramp iron or ensuring fluid systems are contaminant-free, MPI helps automotive manufacturers:

-

Improve part quality

-

Reduce downtime

-

Automate scrap removal

-

Meet strict OEM standards

-

Lower maintenance and production costs

Turnkey Solutions for Automotive Manufacturers From Magnetic Products, Inc

-

Protects High-Precision Equipment

Magnetic separators and filters prevent ferrous contaminants from damaging stamping dies, machining centers, and welding cells, reducing downtime and costly tooling replacement.

-

Supports Lean and Automated Production

MPI systems are designed for hands-free operation, helping automotive manufacturers meet lean manufacturing goals with minimal operator intervention.

-

Improves Quality Control

By ensuring that parts and fluids are contaminant-free, MPI solutions help maintain surface finish integrity, prevent coating defects, and avoid weld failures, which are critical for OEM and Tier 1 quality standards.

-

Streamlines Scrap Handling

Electric scrap shakers and magnetic conveyors efficiently manage metal offcuts from press lines, eliminating manual scrap removal and reducing trip hazards.

-

Enhances Workplace Safety

Enclosed, self-cleaning magnetic systems reduce exposure to sharp scrap and hot equipment, improving safety compliance and ergonomics on the factory floor.

-

Reduces Maintenance Costs

Tramp metal removal upstream of sensitive equipment leads to longer machine life and reduced unscheduled maintenance, which in turn saves money over time.

-

Compact, Space-Efficient Designs

MPI systems integrate into tight press pits, conveyor lines, and machining cells without disrupting material flow or floor layout.

-

Customizable for Line and Cell Integration

MPI products are available in manual, quick-clean, or self-clean designs and can be tailored to stamping presses, robotic welding lines, or CNC machining systems.

How Does the Automotive Industry Use Magnets and Industrial Conveyors?

| MPI PRODUCT TYPE | WHERE | WHY | WHEN | HOW |

|---|---|---|---|---|

| Electric Scrap Shakers (M-10 and M-50 Series) | Under stamping presses or forming stations | Automatically conveys trim scrap away from dies into bins | Oscillating motion drives scrap along attached troughs—no belts or air required | Used continuously during press operation to prevent buildup and downtime |

| Sheet and Plate Separators | At coil-fed lines and robotic destackers | Separates oily or stacked sheet metal for smooth de-stacking and feeding | Magnetic fields induce repelling forces between sheets | Installed at the beginning of stamping and blanking operations |

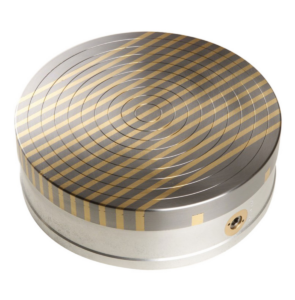

| Magnetic Conveyors (Beltless or Belt-Driven) | Under dies or forming stations to remove parts or scrap | Move ferrous material without external belts or rollers | Internal magnets carry material along a sealed track | Ideal for wet/oily environments or where exposed belts are not preferred |

| Drum Separators | In scrap reclamation or coolant return systems | Remove ferrous fines from high-volume metal flows | Magnetic drum captures and discharges metal while clean material continues | Used during bulk material recycling or coolant system filtering |

| Magnetic Filters (for Coolant & Lubricants) | In coolant return lines of machining centers or grinding machines | Remove microscopic metal particles to improve tool life and surface finish | Magnetic rods or bars capture fine contaminants before fluid recirculates | Used continuously in CNC, lathe, or grinding processes |

| Plate Magnets and Magnetic Chutes | In gravity or chute-fed material handling systems | Protect downstream sensors, actuators, and assembly components | Attracts and traps ferrous debris in product flow | Ideal for parts feeding stations, bolt bins, or hardware delivery |

| Metal Detectors | On conveyors feeding welding, machining, or assembly lines | Detect non-ferrous and ferrous contaminants not removed magnetically | Sends alert or actuates reject when metal is detected | Used in high-precision production for critical quality assurance |

Automotive Industry Compatible Products from Magnetic Products, Inc

- « Previous

- 1

- …

- 4

- 5

- 6