MPI’s Application Specific Metal Detectors are purpose-built solutions engineered to meet the unique challenges of specialized production environments. These detectors are tailored for operations where standard metal detection systems may struggle due to product effects, space constraints, extreme temperatures, or highly customized material flows. Whether dealing with wet, conductive, high-salt, or high-acid products—or inspecting within confined machinery—MPI develops detection systems that balance precision, adaptability, and reliability.

Designed in collaboration with customers and supported by MPI’s engineering expertise, these detectors are available in a wide range of configurations, including in-line, compact, high-speed, high-temperature, and sanitary options. Advanced signal processing and customizable controls ensure optimal sensitivity while minimizing false rejects. Ideal for industries such as food, pharmaceutical, plastics, textiles, and recycling, MPI’s application-specific detectors deliver consistent contaminant detection without compromising product quality or line efficiency.

The Liquid Metal Detector is specifically engineered for fluid and paste-like products, including sauces, dairy items, baby food, jams, and liquid pharmaceuticals. Designed for seamless integration into pressure or vacuum pipeline systems, it continuously inspects product flow using a high-sensitivity detection cell that accurately identifies ferrous, non-ferrous, and stainless-steel contaminants. The system's hygienic, stainless-steel design is CIP (Clean-in-Place) compatible, supporting fast, sanitary maintenance with minimal downtime. Its high-pressure capability and compact footprint make it ideal for demanding environments where space is limited, and safety is paramount. This detector ensures consistent product purity while protecting both consumers and processing equipment.

The compact metal detector is specifically designed for sausage pumps and stuffer machines, enabling real-time inspection of meat emulsions and fillings during processing. Its small size allows for easy installation in tight production spaces without compromising detection performance. Equipped with high-sensitivity sensors, it effectively identifies ferrous, non-ferrous, and stainless-steel contaminants in challenging high-density and high-fat products. Constructed from hygienic, washdown-ready materials, it complies with stringent food safety standards and supports Clean-in-Place (CIP) processes. An integrated reject valve facilitates the swift removal of contaminated products, thus reducing waste and protecting downstream equipment.

The Pneumatic Lines Metal Detector is designed for installation in both vacuum and pressure conveyor pipelines, making it ideal for the inspection of powders, granules, and free-flowing bulk materials in enclosed systems. Commonly used in the food, plastics, chemical, and pharmaceutical industries, this detector continuously monitors product flow and quickly identifies ferrous, non-ferrous, and stainless-steel contaminants. It features a high-speed, automatic reject mechanism that ensures minimal product loss while maintaining system integrity. With a compact, hygienic design and compatibility with Clean-in-Place (CIP) procedures, it supports safe, efficient operation in high-throughput production environments where contamination control is critical.

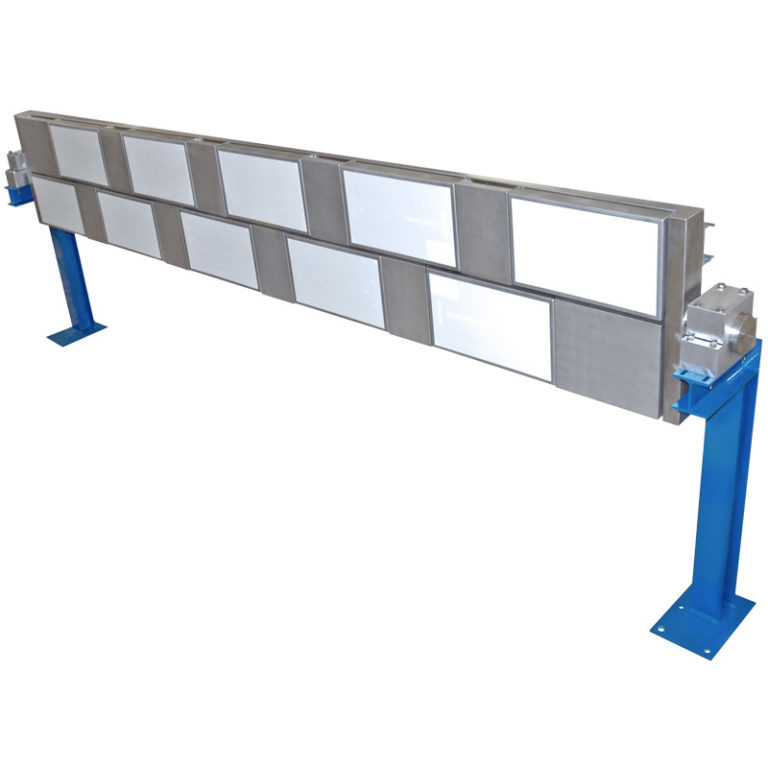

The Metal Detector COMBI is a highly sensitive, multi-segment sensor system specifically engineered for the inspection of wide-format materials such as nonwoven fabrics, transformer boards, paper, and textiles. Its segmented sensor array allows for precise localization of metal contaminants across the full width of the product, enabling targeted rejection that minimizes material loss and maximizes efficiency. Designed for high-speed, continuous processing lines, the COMBI combines durable construction with advanced signal filtering to deliver consistent performance in demanding industrial environments. It is ideal for quality-critical applications where early detection of metal particles ensures product integrity, equipment protection, and industry compliance standards.

The Flat Plate Metal Detector (FL type) is a high-performance detection sensor designed for installation either beneath or above conveyed materials. Engineered for use in continuous production lines, it provides reliable identification of both magnetic and non-magnetic metal contaminants with exceptional sensitivity. The FL type is ideally suited for applications in fleece, textile, foil, and nonwoven material manufacturing, where early detection of foreign metal objects is essential to maintain product quality and protect downstream equipment. Its flat, low-profile design allows for easy integration into compact machinery layouts, while its robust construction ensures stable performance in high-speed, high-volume operations.

Compatibility Check - Application Specific Metal Detector Comparison

Unique Benefits and Considerations

| Application Specific Metal Detector Type | Unique Benefits | Considerations |

|---|---|---|

| Liquid Metal Detector | Ideal for fluid and paste-like products; CIP-compatible; High sensitivity in flowing systems. | Not suitable for solid or dry products; Requires integration with pressurized pipelines. |

| Meat Metal Detector | Compact design for sausage and stuffer machines; Hygienic; High detection in dense, fatty products. | Limited to meat emulsion lines; May require custom reject setup. |

| Pneumatic Line Metal Detector | Designed for vacuum and pressure pipelines; Fast reject system; Maintains flow integrity. | Requires sealed pipeline system; Not suitable for large particulates or non-flowing materials. |

| COMBI Metal Detector | Segmented detection zones; Pinpoint contaminant location; Minimizes waste in wide material inspection. | Designed for wide, flat materials only; Larger footprint in production line. |

| Flat Plate Metal Detector | Low-profile; Easy integration above or below material; Excellent for textile, foil, and fleece production. | Limited to surface or near-surface detection; Not ideal for deep or dense product layers. |

Industries, Applications and Regulations

If you need assistance in selecting the most suitable Application-Specific Metal Detector for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!