Drawer Magnets are designed with multiple durable magnetic tubes to effectively eliminate small to medium-sized ferrous contaminants from free-flowing product streams, thereby enhancing product integrity and protecting processing machinery across various industries such as food and beverage, pharmaceuticals, plastics, chemicals, recycling, and mining. They are the preferred method for capturing fine ferrous tramp metal in medium flows and can handle a variety of separation tasks in mechanical or gravity flow applications. As products flow through the housing, they cascade over staggered magnetic tubes, allowing ferrous contaminants to adhere to the magnets and be drawn away to prevent wash-off. MPI offers different types of drawer magnets for specific processing needs, including high-throughput systems, precision contaminant removal, gravity-fed applications, and hygienic environments. Their commitment to innovative design and performance has made MPI a leader in permanent magnet separators, with various sectors relying on their drawer magnets for the protection of products and equipment.

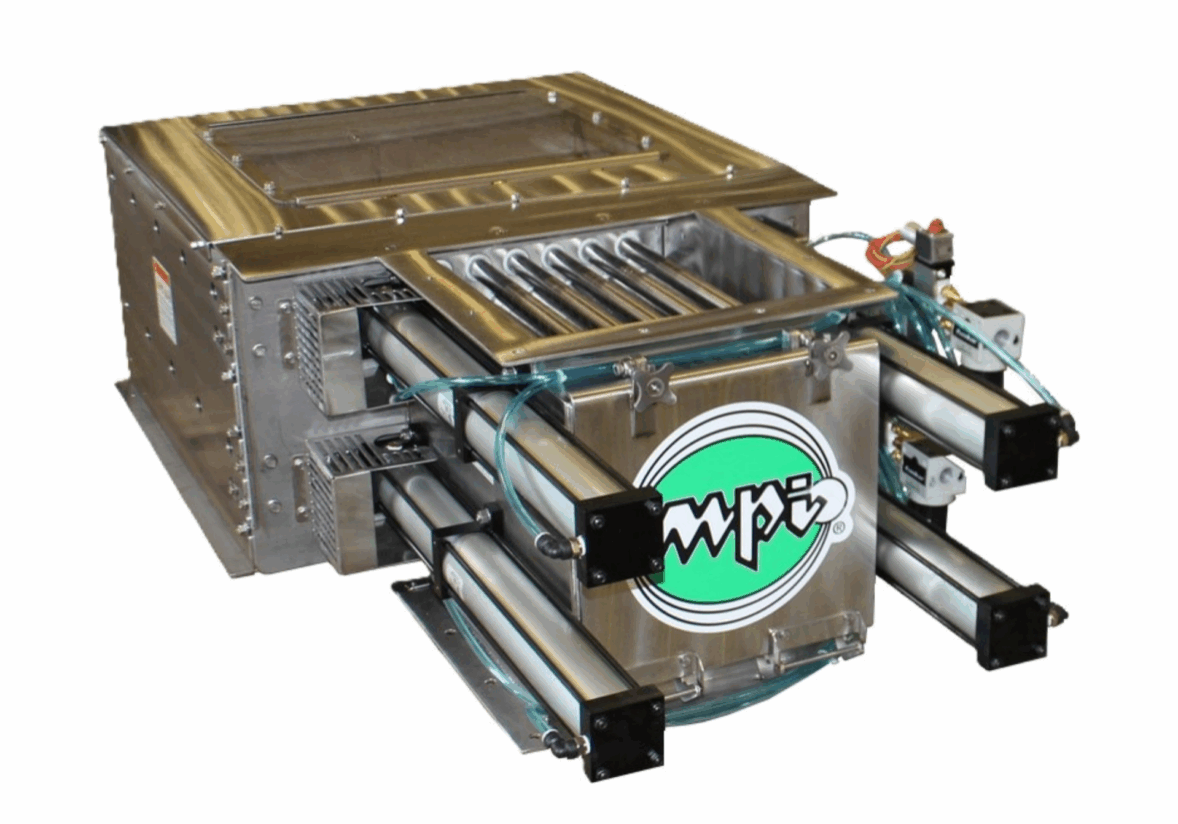

Magnetic Products Inc.'s 2" Continuous-Clean Draw Magnets are engineered for efficient separation of ferrous contaminants from dry powders and granular materials. These high-performance magnets feature an automated cleaning process, suitable for challenging environments. Utilizing one or more rows of 2-inch diameter magnetic tubes, they effectively filter ferrous metals from bulk product streams. Each system includes the patented Intell-I-Mag® technology, enhancing performance with a stronger magnetic field designed to capture small to medium-sized ferrous contaminants, while also allowing for future upgrades.

MPI's 2" Self-Clean Drawer Magnets efficiently capture small contaminants like wire and metal shavings from dry powder or granular products in vertical chutes. They feature a self-cleaning mechanism that automatically removes ferrous materials from magnetic tubes, minimizing manual intervention and downtime. The seamless cleaning process, powered by air or mechanical systems, ensures consistent performance. Utilizing rows of 2” diameter magnetic tubes, these magnets filter ferrous metal from bulk product streams and are compatible with MPI's patented Intell-I-Mag® technology.

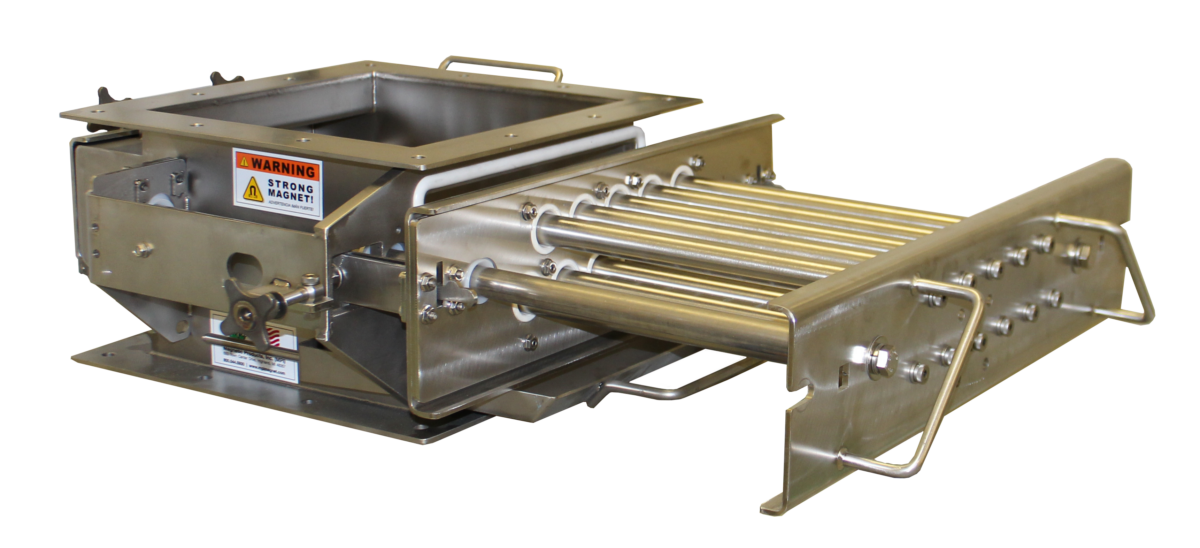

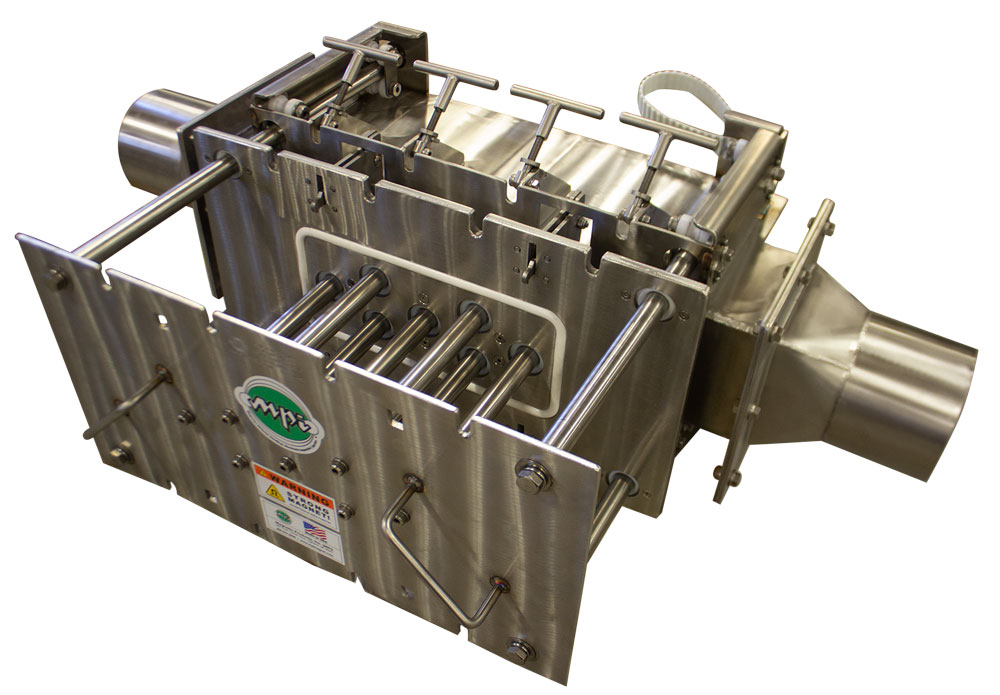

MPI Manual Quick-Clean Drawer Magnets feature two tiers of high-intensity rare earth magnetic tubes that ensure the highest levels of magnetic filtration through direct product contact on the tubes, removing ferrous tramp metal from the product stream. The quick-clean mechanism simplifies maintenance by allowing operators to pull out the magnetic assembly, which then automatically wipes off collected metal contaminants into a designated disposal area. This streamlined process reduces downtime and improves operational efficiency while maintaining peak magnetic performance.

Manual-Clean Drawer Magnets are engineered to eliminate medium and small ferrous tramp metal contaminants from dry, granular, free-flowing product streams in vertically positioned gravity-fed chutes. MPI’s Manual-Clean Drawer Magnets are expertly crafted to extract medium and small ferrous tramp metal contaminants from dry, granular, free-flowing product streams in gravity-fed vertical chutes. They safeguard processing equipment, including milling, extruding, and mixing machinery, while enhancing product quality.

Round Spout Drawer Magnets are designed for easy installation in round applications, effectively removing medium and small ferrous tramp metal contaminants from dry, granular, free-flowing product streams in vertical chutes and spouts. They are particularly suitable for sifter and screener discharge spouts, as they eliminate the need for mounting transitions or flanges. These magnets provide a cost-effective solution for protecting processing equipment and product purity.

Carbon Steel and Stainless-Steel Drawer Magnets are designed with extremely durable carbon or stainless-steel housings and provide effective tramp metal protection for plastic injection molding and extrusion machinery, especially in applications with high levels of tramp metal in plastic regrind materials. These magnets remove ferrous metal impurities from dry, free-flowing materials in gravity-fed systems, offering a robust and cost-effective solution for safeguarding processing equipment and maintaining product integrity.

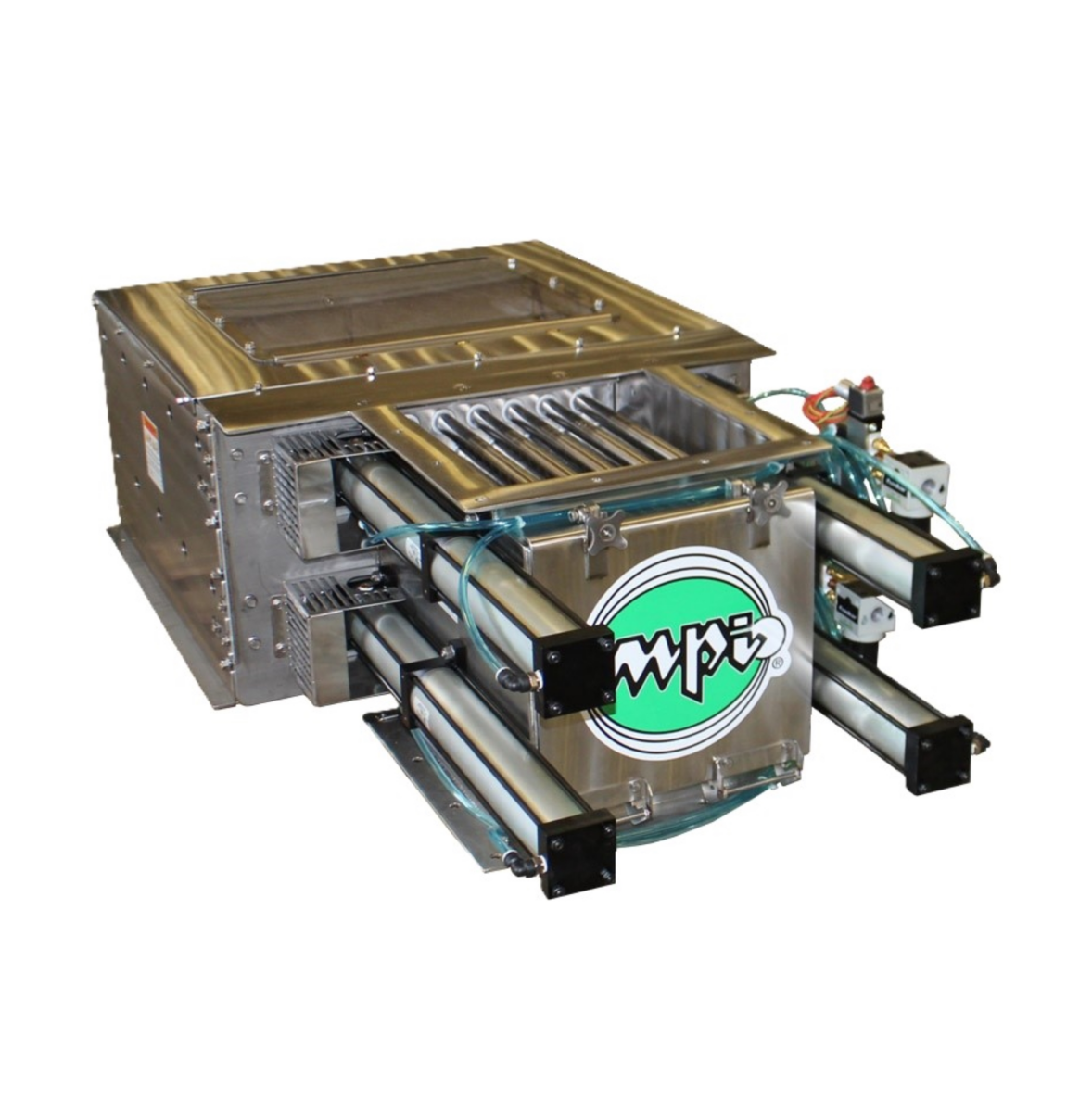

MPI's Continuous Clean Drawer Magnets are designed to efficiently remove small to medium tramp metal from dry powders and granules in gravity-fed chutes. Featuring four tiers of staggered 1-inch rare earth magnetic tubes, the system enhances filtration and prevents clogs. Its continuous cleaning mechanism allows for uninterrupted product flow, utilizing pneumatically controlled cylinders to extract accumulated metal without pausing the filtering process. The magnetic tubes retract through a stripper assembly, which automatically separates and collects metal contaminants into a designated discharge area. This setup minimizes downtime and maintenance while safeguarding processing equipment and ensuring product quality.

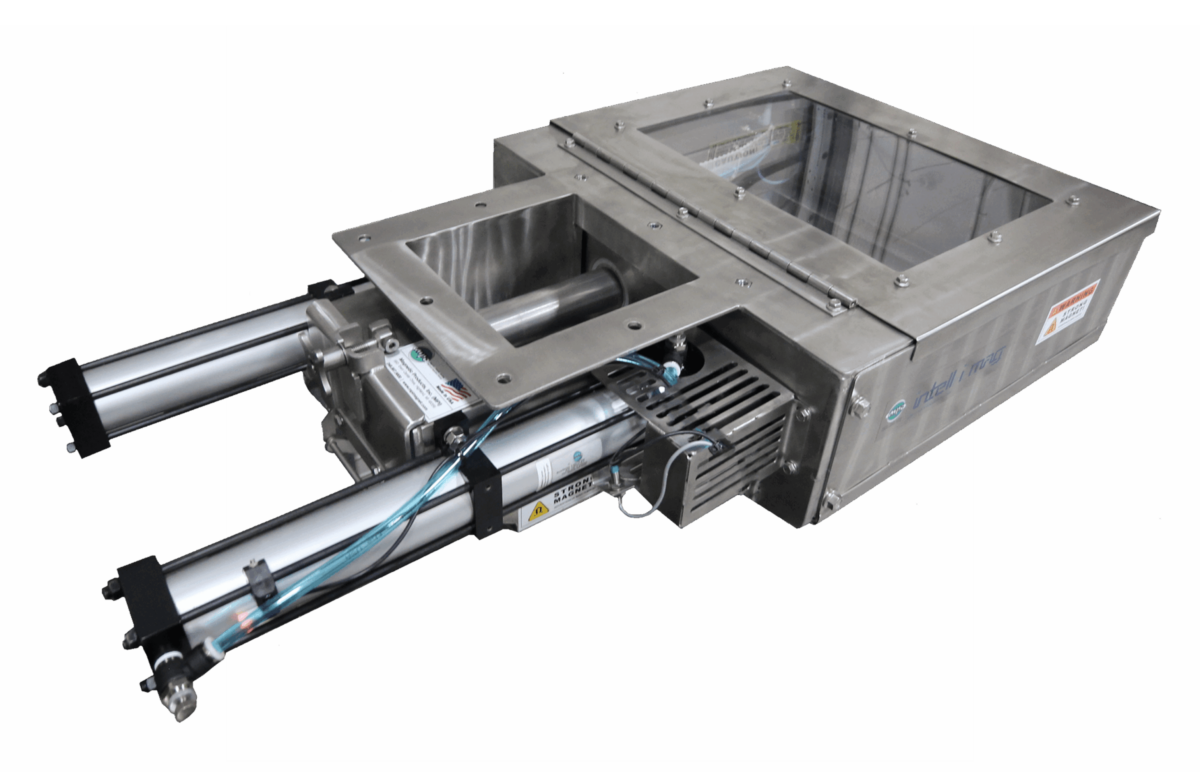

MPI's Self-Clean Drawer Magnets are engineered to capture small metal contaminants in gravity-fed chutes, protecting equipment during milling and mixing while maintaining product quality. They feature dual tiers of 1-inch high-intensity rare earth magnetic tubes arranged in a staggered layout for optimal interaction with the product stream, effectively removing ferrous tramp metal without bridging. The system includes an automated self-cleaning mechanism that requires minimal manual effort; as materials pass through, tramp metal is attracted to the tubes, which pneumatically retract through a stripper assembly to dislodge and collect contaminants. This ensures continuous operation, lessening maintenance requirements and reducing production downtime.

MPI’s Inline Quick-Clean Drawer Magnets offer effective magnetic separation of ferrous contaminants from dry, free-flowing materials in both pneumatic and gravity-fed systems. With a design focused on user convenience, the quick-clean feature enables operators to safely and efficiently extract collected metal, minimizing downtime. These drawer magnets are particularly suited for the food, plastics, chemical, and powder processing sectors, aiding in equipment protection, enhancing product quality, and adhering to industry safety standards, all while facilitating maintenance and optimizing process uptime.

MPI’s Inline Self-Clean Drawer Magnets automate the removal of ferrous contaminants from dry, free-flowing materials in pneumatic and gravity-fed systems. Engineered for continuous operation, these systems eliminate manual cleaning, minimize downtime, and improve worker safety. Powerful magnetic cartridges capture and discharge metal debris without interrupting product flow. Ideal for demanding processing environments in food, plastics, and chemical industries, MPI’s self-cleaning drawer magnets ensure consistent metal control, product integrity, and regulatory compliance with minimal operator intervention.

Compatibility Check - Drawer Magnet Comparison

Unique Benefits and Considerations

| Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| 2" Continuous-Clean Drawer Magnet | Equipped with Intell-I-Mag®. Engineered for 24/7 high-contamination processes. Two tiers of magnets in separate drawers enable cleaning without disrupting processes. The independent top and bottom tiers are cycled separately while the product flows ensuring magnetic protection during the pneumatic cleaning process. It protects equipment while upholding high product quality standards and prevents unnecessary downtime by not having to shut down your process to find your magnetic separator did not need to be cleaned. | Highest initial cost. May not be necessary for small-scale or intermittent applications. |

| 1" Continuous-Clean Drawer Magnet | Engineered for 24/7 high-contamination processes. Four tiers of magnets in two separate drawers enable cleaning without shutting down production. It protects equipment while upholding high product quality standards and prevents unnecessary downtime by not having to shut down your process during the cleaning cycle.Four tiers of magnets in two separate doors enable cleaning without disrupting processes. Protects equipment while upholding high product quality standards. | High initial cost. May not be necessary for small-scale applications. More prone to product bridging in applications with larger product particle sizes. Not Intell-I-Mag® compatible. |

| 2" Self-Clean Drawer Magnet | Equipped with Intell-I-Mag®. Automated cleaning for minimal maintenance needs. It protects equipment while upholding high product quality standards and prevents unnecessary downtime by not having to shut down your process to find your magnetic separator did not need to be cleaned. | Higher initial cost compared to Quick-Clean and Manual-Clean models. Production must be shut down during the cleaning cycle. |

| 1" Self-Clean Drawer Magnet | Two-tiers of staggered magnetic tubes enhance separation efficiency. Protects equipment while upholding high product quality standards. | Higher initial cost compared to Quick-Clean and Manual-Clean models. Production must be shut down during the cleaning cycle. Not Intell-I-Mag® compatible. |

| 1" Manual Quick-Clean Drawer Magnet | Two-tiers of staggered magnetic tubes enhance separation efficiency. Ergonomic-pull drawer design guarantees high product purity. Faster and easier cleaning process than manual clean separators, reducing downtime. | Not Intell-I-Mag® compatible. Higher initial cost compared to manual-clean models. The operator must physically cycle the drawer to clean the magnet tubes, requiring more time and effort than the Self-Clean or Continuous-Clean models. Production must be shut down during the cleaning cycle. |

| Manual-Clean Drawer Magnet | Two-tiers magnetic tubes enhance separation efficiency. Cost-effective and simple to operate. | Not Intell-I-Mag® compatible. Requires the operator to manually remove captured tramp metal by hand, requiring more time and effort. |

| Round Spout Drawer Magnet | Designed for round gravity-fed spouts. Removes the need for mounting transitions in areas with little room. Very easy to integrate and install. The most economical of MPI's drawer magnets. | Not Intell-I-Mag® compatible. May require custom configurations for non-standard spout sizes. |

| Carbon or Stainless-Steel Drawer Magnet | Delivers optimal tramp metal protection in plastic injection molding and extrusion scenarios. Heavy-duty design for managing plastic regrind materials with elevated metal contamination levels. | Not Intell-I-Mag® compatible. Not ideal for all industries or applications. |

| Inline Quick-Clean Drawer Magnets | The manual, fast-pull drawer design simplifies routine cleaning. It is ideal for low—to mid-volume production lines, lowering the upfront cost while providing adequate protection. Efficient manual cleanout. Lower maintenance complexity. Great for batch or shift-based operations. Tool-less access for operator ease. | Requires line stoppage for cleaning. The operator must manually remove contaminants. Less ideal for high-frequency cleaning needs. |

| Inline Self-Clean Drawer Magnets | Automated metal removal improves operational efficiency with continuous, high-volume processes. It minimizes interruptions and enhances safety. It reduces labor costs and improves ergonomics, particularly in hazardous or hard-to-reach areas. It also eliminates downtime typically associated with cleaning. | Higher initial investment. Requires more installation space and control integration. May be overkill for small or batch-only processes. |

Industries, Applications and Regulations

For assistance in selecting the most suitable drawer magnet for your application or for additional customization options, contact Magnetic Products Inc. at info@mpimagnet.com today to speak with our team of experts!