Economical and Dependable Magnetic Protection

Protect your equipment and preserve product quality with MPI’s Suspended Plate Magnets—durable, energy-free magnetic separators engineered to extract ferrous contaminants from fast-moving product streams. Ideal for use over conveyor belts, vibratory feeders, and gravity chutes, these magnets are a cost-effective solution for preventing tramp metal from damaging downstream equipment. Designed with high-strength permanent magnetic circuits and customizable configurations, MPI’s suspended magnets deliver consistent, maintenance-friendly performance even in demanding environments. With no power requirements and enhanced separation efficiency at the discharge point, these separators offer dependable protection 24/7. Available in manual and quick-clean options; Intell-I-Mag® Compatible.

Benefits of the Suspended Plate Magnet From Magnetic Products, Inc

-

Zero Energy Consumption

Operates continuously without electricity—ensuring separation even during power outages and reducing overall operational costs.

-

Enhanced Separation at Discharge Point

Installed over the discharge area where material is in motion, enabling better separation of ferrous contaminants from the loosened product stream.

-

Focused Magnetic Field Design

MPI’s unique internal core projects the magnetic field directly into the material flow—maximizing tramp metal capture while minimizing stray magnetic interference.

-

Flexible Mounting Options

Can be mounted horizontally or inclined above conveyors, feeders, or chutes using adjustable suspension chains for optimal positioning.

-

Custom-Built for Your Process

Available in various sizes, strengths, and configurations to suit specific material handling requirements and throughput capacities.

-

Low Maintenance with Cleaning Options

Tramp metal is held firmly to the magnet face until manually removed; optional slider plates and swipe arms simplify cleaning while reducing operator contact with metal debris.

-

Durable, Non-Deteriorating Ceramic Magnets

High-power permanent magnets resist corrosion and moisture, require no recharging, and offer long-lasting strength without degradation.

-

Safe and Cost-Efficient Alternative to Electromagnets

No wiring, flameproof, corrosion-resistant, and lower in initial and operating costs compared to electromagnet units.

Suspended Plate Magnet Product Details

MPI’s Suspended Plate Magnets are installed directly above conveyor belts, vibratory feeders, or gravity chutes—typically suspended using durable adjustable chains. The magnet is strategically positioned either horizontally or at an angle above the product stream. For maximum efficiency, installation over the head pulley is recommended, especially where belt troughing is minimized, allowing the magnet to be placed closer to the material surface.

As material flows beneath the suspended magnet, the high-intensity magnetic field attracts and lifts ferrous contaminants—including nails, bolts, wires, and other tramp metal—from the product stream. These metal contaminants adhere to the magnet face and remain securely in place until manually removed during routine maintenance.

The discharge point installation leverages the material’s transition from a static to a kinetic state, which naturally separates tramp metal from the flow and enhances magnetic capture. Cleaning is straightforward and can be facilitated by optional accessories, such as swipe arms or slider plates, which allow for easier metal removal with minimal direct handling. For added convenience, units can be mounted on mobile carts, allowing operators to roll the magnet away from the conveyor for safe and easy cleaning.

By eliminating damaging metal contaminants from your process stream, MPI’s Suspended Plate Magnets help extend the life of downstream machinery, reduce downtime, and ensure product purity, making them a vital component of your facility’s metal control strategy.

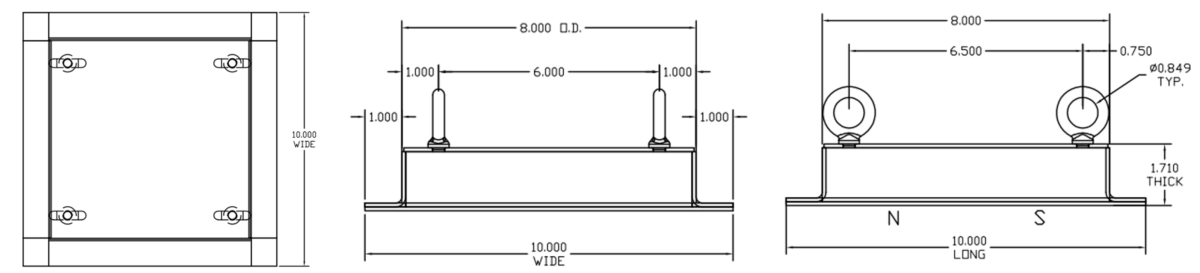

Suspended Plate Magnet Specifications

Suspended Plate Magnet Installations & Variations

Permanent Suspended Plate Magnet with Tramp Metal Collection

Permanent Suspended Plate Magnet Specified with Custom Framing

Permanent Suspended Plate Magnet Installed in Dry Rice Application