MPI's Permanent Magnet Parts Lifters offer a safe and efficient solution for handling small to medium ferrous components during fabrication, welding, and assembly. Designed for easy one-handed use, these lifters enhance speed and ergonomics while decreasing the need for manual gripping tools. Their reliable magnetic strength and compact design facilitate repetitive tasks and improve operator control, making them ideal for lean work cells. Additionally, MPI's Magnetic Rails and Pulleys support the secure, non-contact conveying of ferrous parts in automated systems, integrating seamlessly into various setups like belt or slider-beds. Built for durability and consistent holding power, these magnets reduce product slippage and downtime, promoting efficiency and process control in high-paced environments.

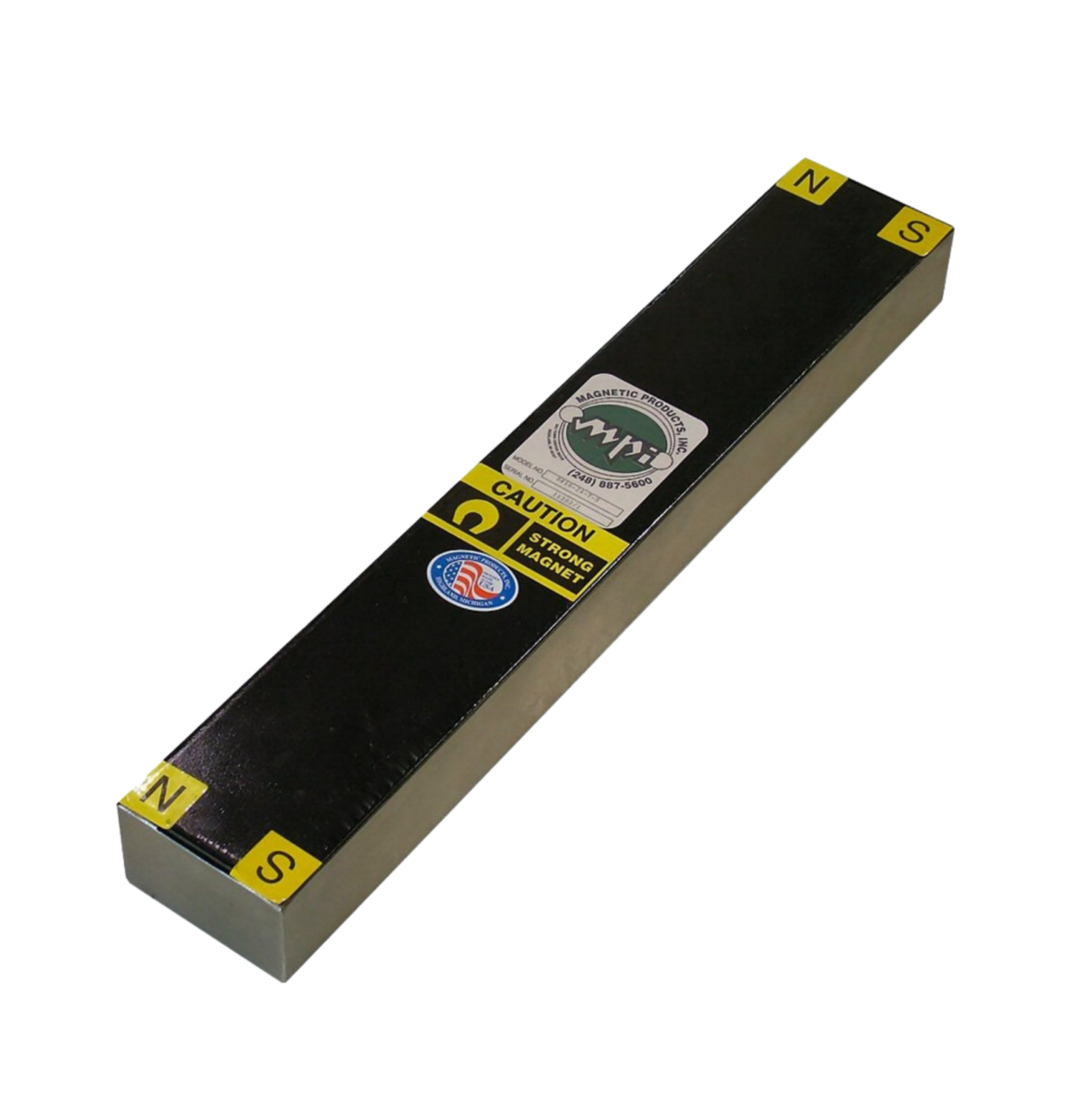

MPI’s Permanent Magnet Parts Lifter (PMPL) is a handheld, fail-safe tool designed for safe, quick lifting and positioning of small ferrous components. With no external power required, it enhances efficiency in welding, assembly, and machining by eliminating finger strain and improving grip consistency. Lightweight and ergonomic, the PMPL reduces operator fatigue, supports lean workstations, and increases throughput in repetitive part handling tasks.

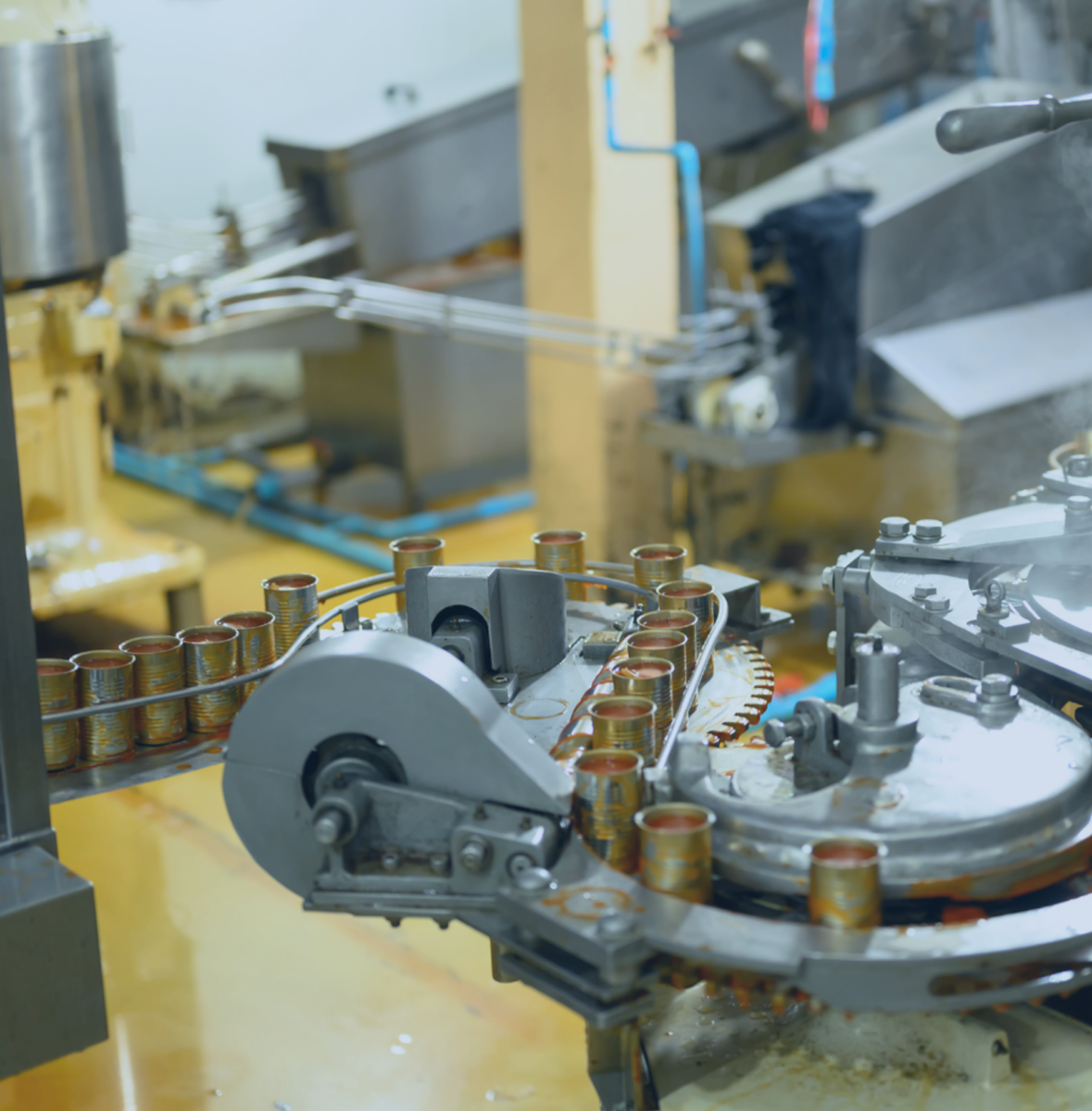

MPI Magnetic Rails deliver precise magnetic control for ferrous part positioning and conveying. Installed beneath or alongside conveyor belts, they hold, guide, or elevate metal parts in high-speed packaging, can handling, and part transfer lines. Their reliable, adjustable strength and rugged design reduce product misalignment and mechanical jams—ensuring smooth automation performance and reducing maintenance in metal transport applications.

MPI’s Workholding Pulleys integrate magnetic strength with rotating motion to securely hold ferrous components during automated conveying or machining processes. Ideal for part transfer, tensioning, or drive mechanisms, these pulleys enhance control in high-speed environments. Their compact design and long-lasting magnetic force reduce slippage, improve alignment, and ensure process stability—making them essential for consistent material flow in precision workholding and conveying applications.

Compatibility Check - Metal Detector Comparison

Unique Benefits and Considerations

| Magnet Type | Unique Benefits | Considerations |

|---|---|---|

| Permanent Magnet Parts Lifter (PMPL) | Safe, ergonomic one-handed lifting of small to medium ferrous parts. No power source required. Increases operator efficiency in repetitive tasks. | Limited to smaller/lighter parts. Manual operation may not suit automation lines. |

| Magnetic Rails | Holds ferrous parts in place during conveying or processing. Adjustable force, low maintenance. Ideal for high-speed, automated lines. | Only effective with ferrous materials. Requires precise system integration. |

| Workholding Pulleys | Combines magnetic holding with rotational drive. Maintains part control during motion. Supports high-speed transfer setups. | More complex to install and align. Best suited for systems with tight tolerances. |

Industries, Applications and Regulations

For assistance in selecting the most suitable magnetic arm tool, rail, or pulley for your application or for additional customization options, contact Magnetic Products Inc. today to speak with our team of experts!